Structural Manometers

GAO Tek’s structural manometers are devices used to measure pressure differences in structural systems. They ensure the integrity and safety of buildings, vessels, pipelines, and other structures. These manometers can be liquid column, inclined, or digital, providing accurate readings of pressure differentials. GAO’s structural manometers are used in construction, maintenance, and civil engineering applications to monitor structural performance and detect abnormalities in systems such as HVAC ductwork, pipelines, and containment vessels.

GAO Tek’s structural manometers are composed of pressure sensor or transducer, liquid or gas medium, tube or chamber, digital display, reference point, and casing.

The other common names of manometers are pressure gauges, pressure meters, pressure instruments, barometers, liquid column gauges, U-Tube manometers, inclined tube gauges, bourdon tube gauges, differential pressure gauges, vacuum gauges, mercury manometers, absolute pressure gauges, compound gauges, micro manometers, and digital pressure sensors.

Manometer with Long Measure Range (Linearity/Hysteresis)

Manometer with Temp Compensation (USB Communication)

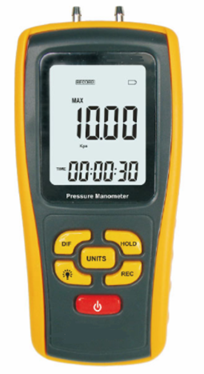

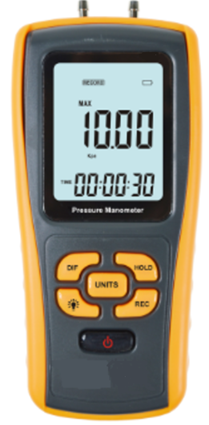

Pressure Gauge for 11 Selectable Measure Units (Data Hold)

Portable Digital Manometer (Blister Card)

Portable Digital Manometer (cmH2O, Bar)

Portable Digital Manometer (Dual LCD)

Portable Digital Manometer (Error Indication)

Portable Digital Manometer (Light Weight)

Portable Digital Manometer (Low Range Indicator)

GAOTek Portable Digital Manometer (Ozin2, ftH2O)

GAOTek Portable Digital Manometer (Under Range Indicator)

Portable Digital Pressure Manometer (Data Hold)

Digital Multi-Function Sound Level Meter (Max Hold Value)

Digital Manometer with USB Interface (Mbar, KPa)

Digital Manometer with USB Interface (High Accuracy)

Digital Manometer with USB Interface (Hg, mmHg)

Digital Manometer with USB Interface (H2O, Psi)

Manometer With Overload Sign (Pressure)

GAO Tek’s structural manometers have the following functions:

- Pressure Measurement: Our structural manometers measure pressure differences in structural systems.

- Structural Integrity Monitoring: GAO’s structural manometers help detect abnormalities and ensure the structural integrity of buildings and systems.

- Troubleshooting and Diagnosis: Our structural manometers aid in identifying and resolving issues in structural systems.

- Research and Development: Our structural manometers contribute to research on structural behavior and advancements.

- Leak Detection: GAO’s structural manometers are capable of detecting leaks in structural systems by monitoring pressure differentials and identifying abnormal variations.

- Environmental Monitoring: GAO’s structural manometers can be utilized to monitor and analyze pressure changes in environmental systems, such as water distribution networks, to ensure efficient and sustainable resource management.

GAO Tek’s structural manometers are rugged, versatile, and precision measurement instruments. They comply with applicable industry standards such as ASME B40.100, ASTM E2512, ISO 376, ANSI/ASHRAE 120, AWWA M45, API MPMS chapter 5, NFPA 24, BS EN 13445-3, ASCE 7, and CSA Z662.

Our structural manometers help our customers comply with relevant U.S. government regulations such as:

- National Institute for Occupational Safety and Health (NIOSH) regulations

- American Petroleum Institute (API) standards and regulations

- Pipeline and Hazardous Materials Safety Administration (PHMSA) regulations

- National Fire Protection Association (NFPA) codes and standards

- Federal Energy Regulatory Commission (FERC) regulations

- Nuclear Regulatory Commission (NRC) regulations

Our structural manometers help our clients in complying with relevant Canadian government regulations such as:

- Canadian Standards Association (CSA) standards and regulations

- Transportation of Dangerous Goods (TDG) regulations

- National Energy Board (NEB) regulations

- Canadian Nuclear Safety Commission (CNSC) regulations

- Technical Standards and Safety Authority (TSSA) regulations

- Natural Resources Canada (NRCan) regulations

- Health Canada regulations, such as the Hazardous Products Regulations (WHMIS)

Our structural manometers have the following applications:

- HVAC Systems: GAO’s structural manometers are used to measure pressure differentials in heating, ventilation, and air conditioning (HVAC) systems, ensuring proper air balance and performance.

- Pipelines: Our structural manometers are utilized to monitor pressure variations in pipelines for oil, gas, water, and other fluids, aiding in leak detection and maintenance.

- Hydraulic Systems: Our structural manometers are employed to measure pressure in hydraulic systems, including machinery, equipment, and industrial processes.

- Industrial Processes: our GAO’s structural manometers are used in various industrial processes that involve pressure-sensitive operations, such as manufacturing, chemical processing, and power generation.

- Aerospace and Aviation: Our structural manometers assist in measuring pressure variations in aerospace and aviation systems, including aircraft, spacecraft, and ground support equipment.

- Structural Monitoring: GAO structural manometers are utilized for real-time monitoring of pressure changes in structural systems, aiding in the assessment of structural integrity and identifying potential issues.

Our structural manometers can be shipped overnight within the continental U.S. and Canada, and can be shipped globally.