Vibration Meters

GAO Tek’s structural vibration meters are rugged, versatile and precision measurement instruments. They comply with applicable industry standards such as ISO 10816, AISC 360-16, ACI 318-19, IEC 60068-2-6 and ASTM E2128-01.

Our structural vibration meters help our customers comply with relevant U.S. government regulations such as:

- Occupational Safety and Health Administration (OSHA)

- American National Standards Institute (ANSI)

- International Building Code (IBC)

- National Fire Protection Association (NFPA)

Our structural vibration meters help our clients in complying with relevant Canadian government regulations such as:

- Canadian Centre for Occupational Health and Safety (CCOHS)

- Canadian Standards Association (CSA)

- National Building Code of Canada (NBC)

- Canadian Fire Alarm Association (CFAA)

The other common names of vibration meters are vibration analyzers, seismometers, vibrometers, vibration sensors, accelerometers, vibration measurement devices, vibroscopes, vibration detectors, vibration monitoring equipment, condition monitoring tools, vibration testing instruments, vibration measurement instruments, vibration data loggers, vibration level meters, vibration diagnostic tools, vibration analysis equipment, dynamic balancing tools, vibration gauges, vibrographs, vibration recorders, vibrocheckers, vibration inspection devices, vibration inspection tools, machine condition monitoring equipment, and structural health monitoring instruments.

GAOTek Digital Acoustics Vibration Meter

GAOTEK 3-Dimensional Vibration Meter

GAOTek Compact LED Stroboscope Vibration Meter

GAOTek Concrete Vibration Analyser

GAOTEK Digital Handheld Portable Vibration Meter

GAOTek Digital Vibration Meter

GAOTek Digital Vibration Meter

GAOTek Digital Vibration Meter

GAOTek Digital Vibration Tension Meter

GAOTek Digital Vibration Tester

GAOTEK Digital Vibrometer with Displacement Tester

GAOTek Display Digital Vibration Meter

GAOTEK Handheld Laser Vibrometer

GAOTEK Handheld low Frequency Vibrometer

GAOTek High Accuracy Vibration Meter

GAOTEK Industrial Vibration Meter Probe

GAOTEK Mini Digital Vibrometer

GAOTek Multi Channel Vibration Meter

GAOTek Pen-Type Vibration Meter

GAOTEK Portable Digital Vibration Test Meter Measuring Instrument Equipment

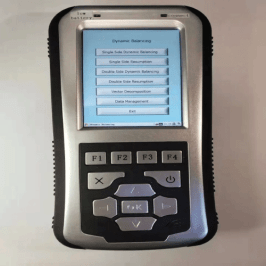

GAOTek Portable Dual Channel Vibration Analyzer Balancer

GAOTek Portable Probe Vibration Meter

GAOTek Portable Probe Vibration Meter

GAOTek Portable Split Vibration Meter

GAO’s structural vibration meters are composed of accelerometer, signal conditioner, display unit, data storage, battery, cables and connectors, cables and connectors.

GAO’s structural vibration meters are specialized vibration meters that are used to measure and analyze the vibrations in buildings, bridges, and other structures. They are designed to detect and monitor vibration levels that can indicate structural damage or fatigue, and provide data that can be used to assess the integrity and safety of the structure. Our structural vibration meters use accelerometers and other sensors to measure vibration levels in terms of acceleration, velocity, or displacement.

GAO Tek’s structural vibration meters have the following functions:

- Assessing structural health: GAO’s structural vibration meters are used to assess the health of buildings, bridges, and other structures by measuring their natural frequencies and detecting any changes or abnormalities. This information can be used to identify potential structural issues and make recommendations for repairs or maintenance.

- Monitoring environmental vibrations: Our structural vibration meters are used to monitor the levels of vibrations caused by environmental factors such as wind, traffic, and construction activities. This information can be used to assess the impact of these factors on the structural integrity of buildings and other structures.

- Research and development: GAO’s structural vibration meters are used in research and development projects to study the behavior of buildings and other structures under different conditions.

Our structural vibration meters have the following applications:

- Industrial Equipment Monitoring: GAO’s structural vibration meters are used to monitor the vibrations of industrial equipment such as turbines, pumps, and motors. By measuring the vibrations, engineers can identify potential problems with the equipment and schedule maintenance before failures occur.

- Seismic monitoring: Our structural vibration meters are used to monitor the levels of vibrations caused by earthquakes and other seismic events. This information can be used to assess the safety of buildings and other structures during and after seismic events.

- Compliance monitoring: Many buildings and structures are subject to regulations and standards related to vibration levels. GAO’s structural vibration meters are used to ensure compliance with these regulations and to identify any potential issues that could lead to non-compliance.

Our structural vibration meters can be shipped overnight within the continental U.S. and Canada and can be shipped globally.