Description

Overview

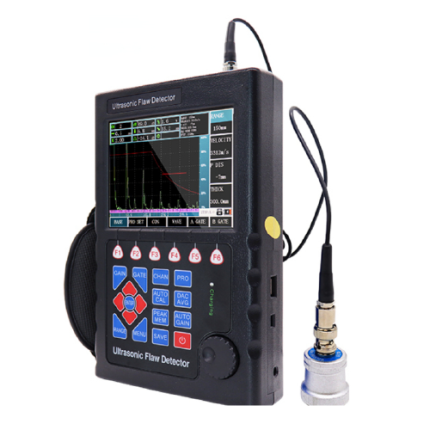

GAOTek Flaw Detector with 100 Independent Setup (3 Staff Gauge) is a portable industrial non-destructive flaw detector, which can rapidly inspect, evaluate and diagnose various defects (crack, inclusion and pinhole, etc.) in a work piece without destruction. This instrument can be widely used in any fields that need defect inspection and quality controlling e.g. manufacturing industry, metallurgical industry, metal working, chemical industry, etc., also be broadly used in the active safety inspection and service-life evaluation in such fields as aerospace, railway transportation and boiler pressure vessels, etc. It is an essential instrument for non-destructive inspection industry.

When the ultrasonic wave propagates in a job, one can detect the defect in it by the influence on the propagation of ultrasonic wave based on the acoustic characteristic demonstrated by the defect in the material. Based on this principle, by using ultrasonic wave one can measure such defects as crack, pinhole and inclusion in such media as metal, non-metal and composite, etc.

Key Features

- Automated calibration of transducer zero offset and/or velocity

- Automated gain, Peak Hold and Peak Memory

- Automated calculation of the size of flaw with wide bottom type in AVG function Automated display with precise flaw location

- Automated switch with three staff gauge

- High contrast viewing of the waveform from bright, direct sunlight to complete darkness and easy to read from all angles

- Large memory size of 500 A graph

- USB port present and easy communication with PC

- High-speed capture with very little noise

- Solid metal housing (IP65) and 6 dB DAC functions

- Li battery with continuous working time up to 10 hours

- Easy lock and unlock function of system parameters and electronic clock calendar Powerful pe software and reports can be exported to excel

Technical Specifications

| Range of scanning | 0 – 236.22 in (6000 mm) |

| D-delay | -20 ms — +3400 ms |

| P-delay | 0.0 – 99.99 ms |

| MTLVEL | 1000 m/s – 15000 m/s |

| Frequency range | 0.5 MHz — 10 MHz |

| Gain adjustment | 0 – 110 dB |

| Reject | 0% – 80 % of screen height, step: 1%

|

| Vertical linear error

|

Vertical linear error is not more than 3%

|

| Horizontal linear error

|

Not more than 0.2 % in the scanning range

|

| Sensitivity Leavings

|

>62 dB |

| Dynamic range

|

>34 dB |

| Alarm | Three modes, i.e. forbidden wave, loss wave and auto |

| A – Scan display area | Full screen or local, A-Scan display freezing and de-freezing A-Scan filling |

| Data save | 500 A-Scan images (including setting of instrument) |

| Battery | Li battery 7.4V 4800 mAh

|

| Weight | 3.97 lbs (1.8 kg) |

| Power adaptor | Input 100 V – 240 V/ 50 Hz – 60 Hz

Output 9 V DC/15 A |

| Working temperature | -4 °F to – 58°F (-20°c – 50°c) |

| Working humidity | 20% – 90% |

| Overall Humidity | 9.45 in x 7.09 in x 1.97 in (240 mm 180 mm x50 mm) |