Description

Overview

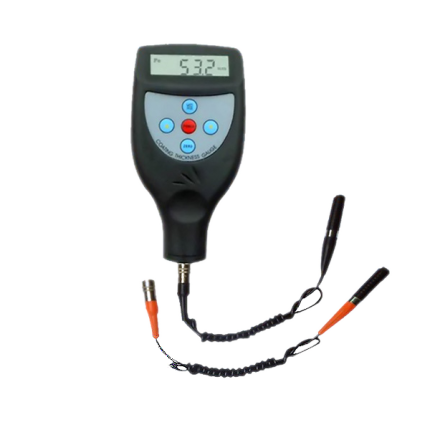

GAOTek Thickness gauge uses Hi-sensible sensor for precise measurement in Metric/Imperial values with built-in beep sound indication. This product is suitable for monitoring all kinds of vibrating mechanical facilities, specially the vibration measurement of rotating and reciprocating machinery. The unit can also measure acceleration, velocity and displacement, which is widely used in mechanical manufacturers.

Key Features

- Zero point, two point and basic, three different calibration

- Measuring mode: Single, Continually and Difference

- Data store/ Data recall/ Data delete function

- Data Analysis: Average, Maximum, Minimum, Standard deviation and measuring times

- Beep sound indication

- Measure in Metric/Imperial

- A LCD backlight display that visually displays the value of the measurement and its state.

- Accurately measures the three important values that are used in a variety of fields, which are acceleration, velocity and displacement.

- Gives the user the choice of changing the vibration frequency.

- A high sensitivity probe for accurate measurements

- The sensitivity probe is equipped with a long and a short probe head which allows for different measurement situations.

- A low power indication function

- An automatic power-off function for battery saving

- Portable, compact and easy to use device that allows the user to use the device anywhere.

- Equipped with an AC signal output interface

- Backlight LCD display

Technical Specifications

| Range | 0 to1800 m |

| Resolution | 0.1um/1 m |

| Accuracy | (3%H+1) |

| Technical parameter | Technical index |

| LCD display | 3 1 /2 display |

| Power supply | 3*1.5V AAA alkaline battery |

| Operation current | Around 25mA |

| Battery life | Continuously 20 hour |

| Auto off | 1 min. |

| LCD backlight function | 7 second |

| Operation temperature | 0 to 40 |

| Operation humidity | 10 to 95%RH |

| Low battery indication | 2.8V 0.2V |

| Product size | 2.8×1.38 x5.7in (72x35x145mm) |

How to Use

- An even firmly-coated standard piece with a known thickness could be used as a Standard Piece, and in terms of the application of this product, the coating must be non-magnetic.

- Substrate: The standard substrate’s roughness and magnetism must be close to those of the material to be measured. To identify the suitability of the substrate, compare the outputs from the standard piece with the material to be measured.

- If the thickness of the material is in the range of the regulated, two methods could be selected to calibrate. To calibrate a metal Standard Piece with the same thickness as the material to be measured; use a similar magnetic and electricity standard metal gasket piece which have enough thickness for calibration. Be sure there is no spacing between substrates.

- If the curvature of the material is too big to be calibrated on the flat surface, please ensure that the coated standard piece’s curvature has the same thickness as the material to be measured.