Overview

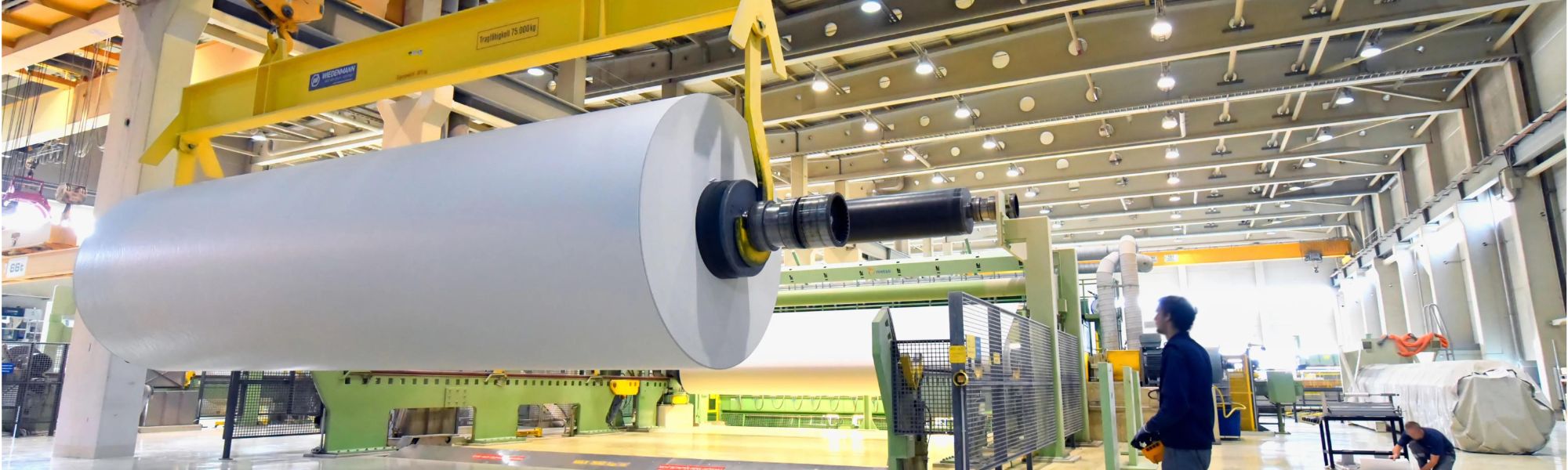

The paper and pulp industry are responsible for producing paper, paperboard, and paper-based products, as well as manufacturing pulp, the key raw material used in paper production. This sector is vital for creating a wide array of items like packaging, printing materials, writing surfaces, and tissues. The process of papermaking involves several stages, starting with pulping, where wood or plant sources are broken down into fibers through chemical, mechanical, or semi-chemical methods. Following pulping, bleaching might occur to enhance brightness and whiteness. The resulting pulp is mixed with water to form a slurry, which is then transformed into sheets via methods like paper machines. After pressing and drying, the paper is often finished with processes like calendaring and coating to meet specific requirements. This versatile industry has embraced sustainability through recycling and eco-friendly practices, continually adapting to minimize its environmental footprint.

Despite digital advancements, the paper and pulp industry remains essential, serving as a foundation for communication, packaging, and various daily items. Depending on specific features and functions, GAO Tek’s “Ion meters” are sometimes referred to as Ion Concentration Analyzers, Ion Selective Electrodes (ISE), Ion Measurement Devices, Ion Sensing Instruments, Ion Analytical Instruments and Ion Detection Meters.

GAO Tek’s ion meters have the following applications in paper and pulp industry:

- Effluent Monitoring: GAO paper and pulp industry generates wastewater containing various chemicals and ions from the pulping and bleaching processes. Ion meters can be used to monitor the concentration of ions such as chlorine, sulfate, and sodium in effluent streams. This ensures compliance with environmental regulations and helps in controlling the quality of discharged water.

- Chemical Recovery: GAO Tek Chemical recovery processes in pulp production involve recycling chemicals like sodium hydroxide and sulfuric acid. Ion meters can be used to monitor the concentration of these ions in different stages of the recovery process, ensuring efficient and cost-effective chemical reuse.

- pH Monitoring: Maintaining the correct pH levels in various stages of paper production is crucial for optimal results. Ion meters equipped with pH electrodes can accurately measure the acidity or alkalinity of the pulp, water, and chemical solutions used in the process.

- Control of Additives: Additives like sizing agents, fillers, and retention aids are used to modify paper properties. Ion meters can be employed to monitor the concentration of ions related to these additives, helping maintain consistent product quality.

- Water Quality Management: The quality of water used in the paper and pulp industry impacts the final product’s quality. Ion meters can test the water for ions that might interfere with papermaking processes or affect the quality of the end product.

- Dissolved Salt Analysis: Some paper products, such as packaging materials, require specific levels of salt content to enhance properties like water resistance. Ion meters can measure the concentration of ions like chloride, which is a component of salts.

More information on ion meters and their applications in other industries can be found on this page Water Ion Meters.

This category page lists related ion meters Chemical & Life Sciences Testing Products.

Complying with Paper and Pulp Industry Standards

GAO Tek’s ion meters comply or help our customers comply with the paper and pulp industry standards such as:

- ISO 10703:2007

- ISO 10704:2002

- ISO 12677:2016

- TAPPI T 401

- TAPPI T 222

- ASTM D1695-20

Complying with Government Regulations

GAO Tek’s ion meters comply or help our customers comply with the Mexican government regulations such as:

- NOM-001-SEMARNAT-1996: Environmental standards for paper and pulp mills.

- NOM-002-SEMARNAT-1996: Wastewater discharges in the paper and pulp industry.

- NOM-003-SEMARNAT-1997: Air emissions limits for paper and pulp facilities.

- NOM-004-SEMARNAT-2002: Hazardous waste handling in the paper industry.

- NOM-010-STPS-1999: Chemical handling workplace safety.

- NOM-147-SEMARNAT-2014: Classification and management of special handling wastes.

- NOM-023-STPS-2012: Preventive maintenance for machinery and equipment safety.

GAO Tek’s ion meters comply or help our clients comply with the European regulations such as:

- REACH – Registration, Evaluation, Authorization, and Restriction of Chemicals

- CLP – Classification, Labelling, and Packaging Regulation

- WFD – Water Framework Directive

- EUTR – EU Timber Regulation

- BREFs – Best Available Techniques Reference documents

- Waste Framework Directive – Directive 2008/98/EC on waste

- IPPC Directive – Integrated Pollution Prevention and Control Directive (Directive 2008/1/EC)

- LCP Directive – Large Combustion Plant Directive (Directive 2001/80/EC)

- EMAS – Eco-Management and Audit Scheme

- Seveso Directive – Control of Major Accident Hazards Involving Dangerous Substances Directive (2012/18/EU)

Case Studies of Ion meters in Paper and Pulp Industry

Ion meters are sometimes called as ion analyzers, ion detection instruments, ion measurement devices, ion concentration meters, ion sensing equipment, ion selective meters and ion electrochemical Analyzers.

Here are some practical examples of using ion meters in paper and pulp industry:

In the Northeast U.S. paper and pulp industry, ion meters have proven invaluable. Maine’s pulp mill used them to comply with discharge regulations by tracking chlorides and sulfates. A New York mill optimized chemical recovery with sodium hydroxide and sulfuric acid measurements. Massachusetts ensured product quality via ion management, while Vermont improved pulp quality through precise bleaching control. Connecticut’s wastewater treatment was enhanced, Rhode Island’s pH control refined, and Pennsylvania’s chemical dosages optimized. This case studies underscore ion meters’ adaptability, enhancing efficiency, compliance, and sustainability.

In the Midwest U.S. paper and pulp industry, ion meters have demonstrated their value. Ohio’s paper mill relied on them to meet wastewater standards by tracking sulfates and chlorides. In Illinois, ion meters optimized chemical use, cutting costs, and waste in a pulp mill. An Indiana mill used ion meters for consistent product quality, monitoring calcium and magnesium ions. Michigan’s mill achieved precise bleaching control with ion meters, boosting pulp quality. In Wisconsin, ion meters managed wastewater treatment for compliance and sustainability. Iowa’s paper mill-controlled pH levels using ion meters, streamlining production. Finally, a Minnesota pulp mill enhanced efficiency via ion meters, optimizing resource allocation. These case studies underscore ion meters’ varied benefits in the Midwest’s paper and pulp sector.

In the South U.S. paper and pulp industry, ion meters have proven invaluable. Louisiana’s paper mill used them to preemptively ensure compliance with effluent regulations by monitoring ion concentrations. In Texas, ion meters optimized chemical usage in a pulp mill, reducing costs and waste. Florida’s mill upheld product quality with ion meters, meticulously tracking calcium and magnesium ions. Georgia’s mill improved bleaching precision with ion meters, enhancing pulp quality and process efficiency.

In the West U.S. paper and pulp industry, ion meters have played crucial roles. A California paper mill utilized them for effluent management, adhering to discharge regulations by monitoring ions like chlorides and sulfates. In Oregon, ion meters optimized chemical use in a pulp mill, reducing costs and waste by tracking sodium hydroxide and sulfuric acid. Washington’s paper mill upheld product quality through ion control, meticulously monitoring calcium and magnesium ions.

In the Canadian paper and pulp industry, ion meters have proven their value. In British Columbia, a paper mill employed them to meet effluent regulations by tracking ions like sulfates and chlorides. Alberta’s pulp mill optimized chemical use with ion meters, reducing costs and waste via sodium hydroxide and sulfuric acid monitoring. Ontario’s paper mill upheld product quality, meticulously tracking calcium and magnesium ions. Quebec’s mill improved bleaching precision, enhancing pulp quality through ion meters measuring chlorine.

In the Mexican paper and pulp industry, ion meters have been pivotal in ensuring efficient and environmentally sustainable operations. One notable case study revolves around a major paper mill’s adoption of ion meters to monitor and control the chemical composition of their effluent discharge.

In the European paper and pulp industry, ion meters have played a critical role in optimizing processes and ensuring environmental responsibility. A notable case study features a prominent paper manufacturer that implemented ion meters to monitor alkalinity and pH levels during the papermaking process.

GAO RFID Inc. , a sister company of GAO Tek Inc., is ranked as a top 10 RFID supplier in the world. Its RFID, BLE, and IoT ion meters have also been widely used in cosmetics and personal care product formulation.

Use of Ion Meters with Leading Software and Cloud Services in Paper and Pulp Industry

GAO Tek has used or has facilitated its customers to use GAO’s “ion meters” with some of the leading software and cloud services in their applications. Examples of such leading software and cloud services include:

- LabView

- Metrohm tiamo™

- Thermo Fisher SampleManager™

- Hanna Instruments HI-921

- HORIBA OCMA-500

- YSI KorDSS™

- Vision Air 2.0

- Hach SC Controller

- SevenExcellence

- Microsoft Azure

- AWS (Amazon Web Services)

- Google Cloud Platform

- IBM Cloud

- Oracle Cloud

- SAP Cloud Platform

- Salesforce Lightning

GAO Tek’s ion meters and their applications in other industries are listed on this page.

Other related ion meters can be found at this category page.

Meeting Customers’ Demands

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO Tek Inc. and its sister company GAO RFID Inc. together offer a wide choice of testing and measurement devices, network products, RFID, BLE, IoT, and drones.

Fast Delivery

To shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in paper and pulp industry we have worked with to serve our joint customers:

- Accenture

- IBM

- Deloitte

- Cognizant

- Capgemini

- PwC (PricewaterhouseCoopers)

- Wipro

- HCL Technologies

- Infosys

- TCS (Tata Consultancy Services)

- CGI

- Deloitte Canada

- PwC Canada

- Cognizant Canada

- Accenture Canada

- KPMG Canada

- IBM Canada

- TELUS Business Solutions

- MNP (Meyers Norris Penny)

- Softchoice

- ITI Mex

- TecnoPapel

- InfoPulp

- ProPapelTech

- PulpIT Solutions

- PaperTech MX

- PulpITech EU

- EuroPulpSys

- PaperTechEU

- ITIntegraPulp

- PulpNet Europe

- TechPulp Europe

GAO Has Many Customers in Paper and Pulp Industry

The products from both GAO Tek Inc. and GAO RFID Inc. have been widely used in paper and pulp industry by many customers, including some leading companies. Here is more information on applications of GAO RFID Inc.’s products in paper and pulp industry.

Retail Trade & Rental Industry | RFID Solutions

Here are some of GAO’s customers in paper and pulp industry:

- International Paper

- Domtar

- Verso Corporation

- Sappi North America

- Georgia-Pacific

- WestRock

- Resolute Forest Products

- Canfor Pulp Products (Canfor Pulp Limited Partnership)

- West Fraser Timber Co. Ltd.

- Grupo Gondi

- Bio-Pappel

- Kimberly-Clark de México

- Copamex

- Smurfit Kappa Mexico

- Stora Enso

- UPM-Kymmene Corporation

- Mondi Group

- SCA (Svenska Cellulosa Aktiebolaget)