Chemical and Water Viscometer

GAO’s chemical and water viscometers are instruments used to measure the viscosity, or resistance to flow, of fluids in the chemical and water industries. Viscosity is an important physical property of fluids that affects their behavior and performance in many industrial applications.

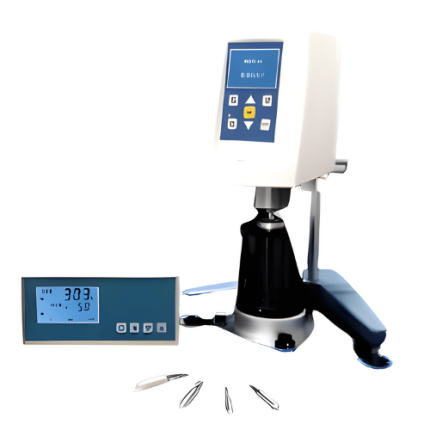

GAO’s chemical and water viscometers are composed of rotating spindle, sample container, temperature control system, control panel, data display and recording system, spindle guards, and power supply.

The other common names of viscometers are viscosity meters, rheometer viscosity analyzers, viscosity testers, flow resistance indicators, fluidity meters, viscous flow meters, shear rate detectors, fluid consistency testers, viscous substance analyzers, viscosity measuring devices, fluid viscosity sensors, thickening rate gauges, flow behavior analyzers, liquid resistance testers, fluid viscosity monitors, shear stress indicators, flow resistance meters, consistency index detectors, viscous fluidity meters, fluid friction analyzers, shear viscosity meters, viscous consistency testers, flow resistance sensors, fluid viscosity profilers, shear rate analyzers, viscous substance profilers, liquid thickness detectors, rheological analyzers, and viscosity sensing devices.

Automatic Kinetic Viscosity Meter Withstand Up to 100 °C – GAOTek

GAOTek Brookfield Dynamic Viscosity Test Instrument

GAOTek Brookfield Viscometers

GAOTek Liquid Brookfield Viscometers

GAOTek Rotational Digital Viscometers

GAOTek 120 W Six Speed Viscometer

GAOTek Adhesive Liquid Viscosity Measurement

GAOTek Automatic Digital Display Rotational Viscometer

GAOTek Automatic Rotational Viscometer

GAOTek Automatic Rotational Viscosity Measuring

GAOTek Brookfield Digital Rotary Viscometers

GAOTek Brookfield Rotational Viscometer

GAOTek Brookfield Rotational Viscometers

GAOTek Brookfield Thermosel Rotational Viscometer

GAOTek Brookfield Viscometer

GAOTek Brookfield Viscometers for Cosmetics Food

GAOTek Clinical Viscometer

GAOTek Cosmetics Rotational Viscometer

GAOTek Cosmetics Rotational Viscometer

GAOTek Digital Brookfield Viscometer

GAOTek Digital Display Brookfield Viscometers

GAOTek Digital Display Viscometer

GAOTek Digital Engler Viscometer

GAOTek Digital Engler Viscometer

GAO Tek’s chemical and water viscometers have the following functions:

- Quality control: GAO’s viscometers are used to ensure that the viscosity of fluids is consistent and within acceptable limits. This is important for maintaining product quality and performance.

- Process optimization: By measuring the viscosity of fluids at different stages of a manufacturing process, our viscometers can help to identify areas where process improvements can be made to optimize production efficiency.

- Product development: Our viscometers are used in the development of new products to determine the optimal viscosity for a given application.

- Troubleshooting: When problems arise in a manufacturing process, GAO’s viscometers can be used to help identify the source of the problem and develop solutions.

- Research: Our viscometers are used for conducting research in the chemical and water industries, where the viscosity of fluids can have a significant impact on their behavior and performance.

GAO Tek’s chemical and water viscometers are rugged, versatile and precision measurement instruments. They comply with applicable industry standards such as ASTM D445, ASTM D446. ISO 3105, ISO 3219, and ISO 1652.

Our chemical and water viscometer comply with relevant U.S. government regulations such as:

- Occupational Safety and Health Administration (OSHA) regulations

- Environmental Protection Agency (EPA) regulations

- Food and Drug Administration (FDA) regulations

- National Institute of Standards and Technology (NIST) regulations

Our chemical and water viscometer comply with relevant Canadian government regulations such as:

- Health Canada regulations

- Environment and Climate Change Canada regulations

- Canadian Standards Association (CSA) regulations

- Transportation of Dangerous Goods (TDG) regulations

Our chemical and water viscometer have the following applications:

- Petroleum and Petrochemicals: GAO’s viscometers are used to measure the viscosity of crude oil, refined petroleum products, lubricants, and other fluids used in the petroleum industry.

- Paints and coatings: Our viscometers are used to measure the viscosity of paint and other coatings to ensure consistent application and drying characteristics.

- Food and beverages: Our viscometers are used to measure the viscosity of food products, such as sauces, dressings, and beverages, to ensure consistent texture and mouthfeel.

- Pharmaceuticals: GAO’s viscometers are used to measure the viscosity of pharmaceutical products, such as suspensions and emulsions, to ensure consistent dosing and ease of administration.

- Cosmetics: Our viscometers are used to measure the viscosity of cosmetic products, such as creams and lotions, to ensure consistency of texture and ease of application.

- Adhesives and sealants: GAO’s viscometers are used to measure the viscosity of adhesives and sealants to ensure consistent bonding and sealing properties.

- Water treatment: Our viscometers are used to measure the viscosity of water and other liquids used in water treatment processes, such as flocculation and sedimentation.

- Biotechnology: Our viscometers are used in biotechnology applications, such as measuring the viscosity of cell cultures and protein solutions.

Our chemical and water viscometers can be shipped overnight within the continental U.S. and Canada, and can be shipped globally.