Structural Flaw Detectors

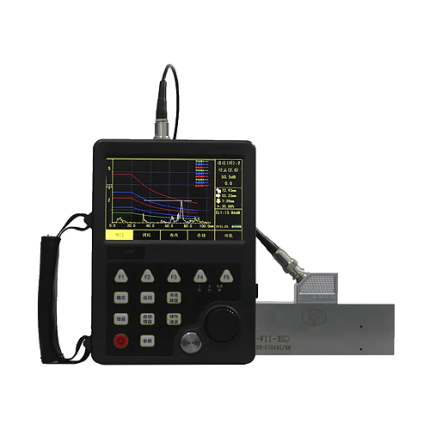

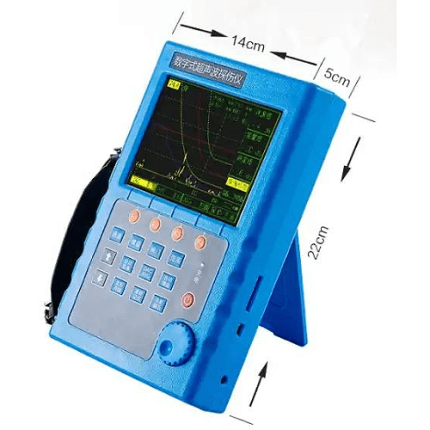

GAO’s structural flaw detectors are devices used to identify defects or flaws in materials, structures, or components. They are primarily used in non-destructive testing (NDT) techniques, which involve testing materials or structures without damaging or altering them. There are various types of structural flaw detectors available, including ultrasonic, radiographic, magnetic particle, liquid penetrant, eddy current, and visual inspection methods. Each type of detector is used to identify different types of flaws, such as cracks, porosity, inclusions, and surface defects. Ultrasonic flaw detectors, for example, use high-frequency sound waves to identify internal flaws in materials, while radiographic flaw detectors use X-rays or gamma rays to penetrate materials and identify flaws.

GAO’s structural flaw detectors are composed of sensor, signal processor, display unit, power source, and data storage.

The other common names for flaw detectors are ultrasonic flaw detectors, non-destructive testing devices, defect inspectors, material integrity analyzers, flaw inspection tools, defect scanners, quality control instruments, flaw assessment devices, flaw assessment tools, imperfection detectors, material inspection devices, ultrasonic testing equipment, NDT inspection tools, and defect identification devices.

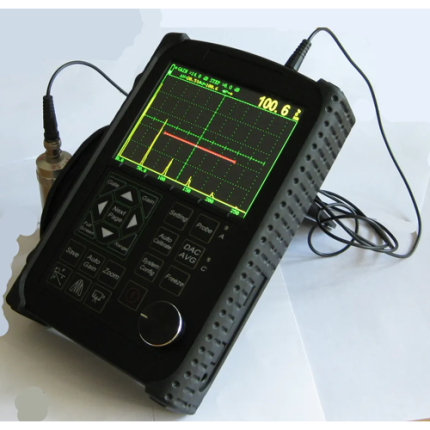

Flaw Detector with Auto Calibration (Spheroidization Rate)

GAOTek 4 G WIFI GPS Camera

GAOTek Automated Display Ultrasonic Flaw Detector

GAOTek Automated Ultrasonic Flaw Detector

GAOTek Automated Ultrasonic Metal Flaw Detector

GAOTek Best Price Digital Ultrasonic Flaw Detector

GAOTek Coating Flaw Detector

GAOTek Coating Flaw Detector

GAOTek Concrete Crack Width Detector

GAOTek Concrete Flaw Detection Machine

GAOTek Concrete Flaw Detector

GAOTek Concrete Flaw Detector Tester

GAOTek Concrete Ultrasonic Flaw Detector Concrete Flaw Detector Tester

GAOTek Current Flaw Detector

GAOTek Curve Detector Testing Machine

GAOTek Detection Ultrasonic Flaw Detector

GAOTek DGT FD800 Ultrasonic Flaw Detector

GAOTek Digital Flaw Detector

GAOTek Digital Flaw Detector

GAOTek Digital Metal Flaw Detector

GAOTek Digital Portable Ultrasonic Flaw Detector

GAOTek Digital Ultrasonic Flaw Crack Detector

GAOTek Digital Ultrasonic Flaw Crack Detector

GAO’s structural flaw detectors have the following functions:

- Non-destructive testing: Our structural flaw detectors are used for non-destructive testing, which allows the inspection of a structure without causing any damage to it. This can be important for assessing the safety and integrity of structures without requiring costly repairs or replacements.

- Identification of defects: GAO’s structural flaw detectors can identify a range of defects, including cracks, voids, and corrosion, which can compromise the strength and safety of a structure.

- Location of defects: Our flaw detectors can accurately locate defects, which allows for targeted repair and maintenance.

- Monitoring of changes: GAO’s flaw detectors can also be used for monitoring changes in structures over time, such as the growth of cracks or the expansion of voids. This can help identify potential problems before they become serious.

- Quality control: Our structural flaw detectors can be used in quality control processes to ensure that structures are built to the required standards and specifications.

GAO’s structural flaw detectors are rugged, portable, versatile and precision measurement instruments. They comply with applicable industry standards such as ASTM E1444, ASTM E164, ASTM E543, ISO 5577, ISO 3452, and EN 12668.

Our structural flaw detectors help our customers comply with relevant U.S. government regulations such as:

- Occupational Safety and Health Administration (OSHA)

- Federal Aviation Administration (FAA)

- American Society of Mechanical Engineers (ASME)

- National Institute of Standards and Technology (NIST) technology

- Federal Railroad Administration (FRA)

Our structural flaw detectors help our customers comply with relevant Canadian government regulations such as:

- Canadian Centre for Occupational Health and Safety (CCOHS)

- Canadian General Standards Board (CGSB)

- Natural Resources Canada

GAO’s structural flaw detectors have the following applications:

- Construction: Our structural flaw detectors are used in the construction industry for quality control, to detect defects in new structures, and ensure they meet the required safety and regulatory standards.

- Maintenance and inspection: Our flaw detectors are used for regular inspections of structures, such as bridges, buildings, and pipelines, to identify defects or damage that may require repair or replacement.

- Automotive industry: GAO’s flaw detectors are used in the automotive industry to inspect and detect defects in parts such as engines, chassis, and bodywork.

- Manufacturing industry: Our structural flaw detectors are used in the manufacturing industry for quality control and to detect defects in products, such as metal castings, plastic molds, and composite materials.

- Oil and gas industry: GAO’s flaw detectors are used in the oil and gas industry to inspect pipelines and other infrastructure for cracks, corrosion, and other defects that can lead to leaks or failures.

Our structural flaw detectors can be shipped overnight within the continental U.S. and Canada, and can be shipped globally.