Description

Features

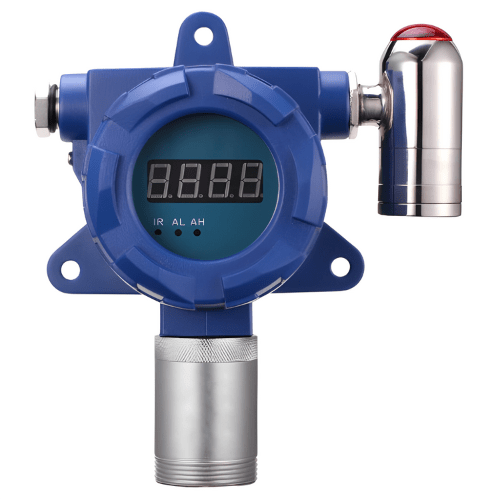

- Being compatible with all kinds of controlled alarms, PLC, DCS and other control system, can be remote monitored

- Explosion-proof design, fast, reliable and stable. Explosion-proof grade: Ex d II CT6

- With self-calibration function, and three standard keys will be used to realize on-site maintenance

- Monitor the ammonia gas concentration in environment or pipeline and alarm

- Two-stage alarm with sound and light, alarm point is settable

- Infrared ray controller can remote control alarm point settings, zero calibration, and address modification

- Can output one or two on-off signals, can drive ventilator or solenoid valve and other external devices

Technical Specifications

| Gas Detected | Styrene |

| Detection Principle | PID |

| Install Methode | Wall-mounted, piping type, flow-type (according to the detected environment) |

| Measure Range | 0 ppm to 50ppm,0 ppm to 100ppm,0 ppm to 500ppm,0 ppm to 1000ppm, 0 ppm to 2000ppm, 0 ppm to 5000PPM |

| Resolution | 0.01 ppm, 0.1 ppm, 1 ppm |

| Precision | ≤± 3% F.S. |

| Signal Output | 4 MA to 20 MA, RS485, relay |

| Response Time | ≤10 S |

| Repeatability | ≤±1 % |

| Zero Shift | ≤±1 %(F.S/year) |

| Temperature | 28 ºF to 122 ºF (-20 ºC to 50 ºC) |

| Explosion-Proof | Ex d II CT6 |

| Recovery Time | ≤10 S |

| Linearity Error | ≤±1 % |

| Humidity | 0 % to 90 %RH |

| Degree Of Protection | IP65 |

| Operating Time | 24 h |

| Dimensions | 7.09 in x 5.90 in x 3.54 in (180 mm x 150 mm x 90mm) |

| Weight | ≤3.53 lb (1.6 kg) |