Description

Overview

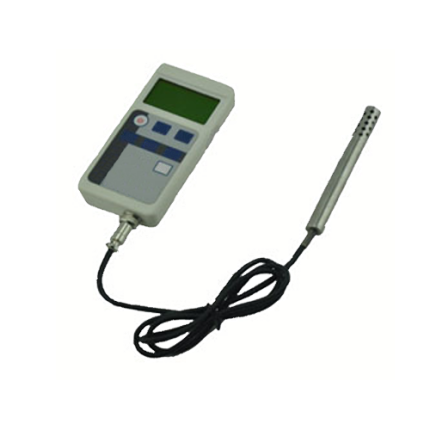

GAOTek Coating Thickness Gauge with 0 Span Calibration (Light Weight) is designed to magnetic and nonmagnetic materials in high resolution and wide measuring range of 1 μm to 1250 μm. It uses magnetic induction method and eddy current method to measure thickness of magnetic coating on non-magnetic base. This light weight instrument is suitable for use in harsh conditions. This instrument provides under voltage and error indicator, automatic shutdown, zero calibration, span calibration and prompt beep operation function. This rugged and versatile device can be used in the field of chemical industry, commodity inspection, manufacturing, metal processing industry and other testing.

Key Features

- Zero calibration and span calibration

- Automatic Shutdown

- Under voltage and error indicator

- Prompt beep operation

- Light weight, portable and durable

- Ruby wear probe

- Suitable for use in harsh conditions

Technical Specifications

| Measuring Principle | Magnetic induction method and Eddy current method |

| Measuring Range | 1 μm to 1250 μm |

| Workpiece | convexity of the minimum radius of curvature (in) 0.19, (mm) 5/Au 25 |

| Minimum Contact Area of Diameter | 0.39 in x 0.39 in (10 mm x 10 mm) |

| Resolution | 1 μm |

| Measurement Accuracy | ± [(1~3) H +1] μm (full scale calibration) |

| Matrix Street Thickness | 0.007 in (0.2 mm) |

| Power | Four 1.5-volt AAA battery |

| Temperature | 32 °F to 140 °F (0 °C to 60 °C) |

| Humidity | 20 % to 75 % |

| Dimensions | 4.40 in × 2.71 in × 1.10 in (112 mm × 69 mm × 28 mm) |

| Weight | 0.18 lbs (82 g) (without batteries) |

Additional Information

Materials

Gauge, Reference Fe Base, Certified Plastic Shims, Battery

Operation Guide

- Power-on and Warm-up

Keystroke once; wait until ![]() is displayed on the LCD. Now the gauge is ready for measurements.

is displayed on the LCD. Now the gauge is ready for measurements.

- Zeroing

Keystroke twice; when ![]() is displayed, place flat on surface; hold steady.

is displayed, place flat on surface; hold steady.

After measurement is obtained, ![]() is shown and gauge beeps. Then lift the gauge.

is shown and gauge beeps. Then lift the gauge.

3. Two-Point User Calibration

Keystroke three times; gauge enters into the mode of two-point user calibration.

When ![]() is shown on the LCD, please conduct a measurement on the base. When

is shown on the LCD, please conduct a measurement on the base. When ![]() is shown on the LCD, place Shim S1 on the base and conduct a measurement on Shim S1. When

is shown on the LCD, place Shim S1 on the base and conduct a measurement on Shim S1. When ![]() is shown on the LCD, place Shim S2 on the base and conduct a measurement on Shim S2. When

is shown on the LCD, place Shim S2 on the base and conduct a measurement on Shim S2. When![]() is displayed, it is ready for use.

is displayed, it is ready for use.

4. Unit Change

Keystroke four times; convert from ums to mils or vice versa.

5. Reset

Keystroke five times; gauge resets.

Measurement Range: 0 um–1250 um or 0 mil–50 mil

Accuracy: ± [(1%~3%) H+1 um] Note: H is thickness reading

The device powers down after 60 seconds of no activity.