Description

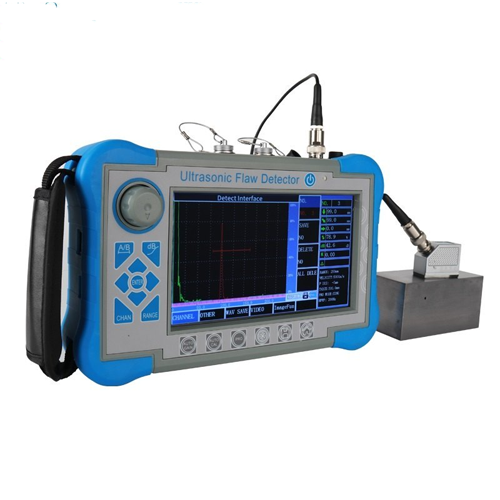

Overview

GAOTek flaw inspection multi-channel detector is a versatile method used to identify hidden defects in various materials, including steel, plastics, composites, and ceramics. It plays a crucial role in weld inspections and is applied to primary metals, infrastructure, petrochemical equipment, in-service testing, manufacturing, and composites. Common applications include examining structural components like beams, pipelines, and aircraft parts for cracks, voids, or other discontinuities.

Feature

- Full Screen Display: Maximizes the visual area for clear echo representation

- Extensive Storage: Can store up to 1000 data sets, including waveforms and parameters

- Precise Measurement: Measures peak values or echo front edges accurately

- Coating-Friendly Thickness Measurement: Measures substrate thickness through coatings without zero calibration

- Peak Memory: Records and displays the highest defect wave for precise defect location.

- Auto Gain Adjustment: Automatically adjusts gain to the set amplitude

- Alarm Alerts: Notifies of incoming or lost waves

- Enhanced Waveform Display: Improves visual contrast for fast scanning without missing data

- Real-Time Clock: Records date and time of saved waveforms

- Display Freeze: Captures waveforms and acoustic range data for later analysis

Technical Specifications

| Working frequency | 0.5 MHz to 15 MHz |

| Sound velocity of material | 1000 m/s to 9999 m/s |

| Operation Mode | Pulse echo, double crystal |

| Pulse shift | 0 in to 39.37 in (0 mm to 1000 mm) |

| Probe zero | 0 us to 199.99 us |

| Gain control | 0 dB to 110 dB (0.1,1 Db to 2,6 dB stepping |

| Vertical linearity error | ≤3% |

| Horizontal linearity error | ≤0.3% |

| Sensitivity margin | ≥60 dB |

| Definition | ≥32 dB |

| Dynamic range | ≥30 dB |

| Average noise level | ≤10% |

| Battery working time | 9 hrs |

| Power supply | 12 V DC, 220 V AC |

| Dimensions | 11 in x 7.5 in x 2.4 in (270 mm x 190 mm x 60 mm) |

| Weight | 4.4lb (2 Kg) including batteries |