Description

Overview

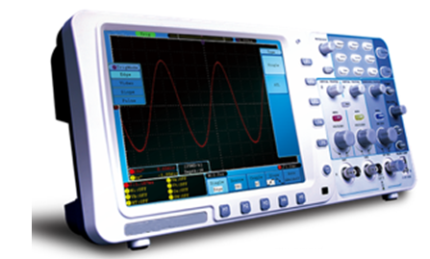

GAOTek Mixed Signal Oscilloscope (Bandwidth 60 MHz/LA-100 MHz, Sample Rate 1 GS/s/LA-2 GS/s, Channel 2 + 1 /LA -16) is a portable all-in-one device designed to detect the average and peak values of wave forms and supports USB transmission with 20 group auto measurement options. It is a 2 in 1 device which combines a digital oscilloscope and a 16 channel logic analyser. It features colour LCD screen, a bandwidth of 60 MHz/ LA- 100 MHz and a sample rate of 1 GS/s – LA- 2 GS/s. The device is capable of performing functions like multiple-waveform calculations, storage and call-out of wave forms, auto-scaling functions etc. This mixed oscilloscope is an all-in-one device which offers a simple front panel with distinct functions, is user friendly and gives the host an ease in operation.

Features

- Dual channel, 2M points on each channel for the Record length

- Reading-out with the cursor

- Twenty automatic measurement functions

- Auto-scale function

- Storage and call-out of waveforms

- Automatic setting function provided capable of fast setting

- Multiple-waveform calculation function

- Implementation of detecting the average and peak values of the waveform

- Built-in FFT function

- Digital real-time oscilloscope

- Colour liquid crystal display of high resolution and high contrast with adjustable back light

- Multiple Language User Interface

- Edge, video, alternate, pulse and slope triggering function

- RS232 or USB communication ports

- Different continuous displaying time

Technical Specifications

| Bandwidth | 60 MHz | |

| Sample Rate | 1 GS/s | |

| Display | 8 inch color LCD, TFT Screen, 640 × 480 pixels | |

| Channel | Dual channels + external trigger | |

| Horizontal Scale (s / div) | 2 ns/div ~ 100 s/div, step by 1 ~ 2 ~ 5 | |

| DC Accuracy (Average) | Average > 16: ± (3 % reading + 0.05 div) for △V | |

| Vertical Sensitivity | 2 mV/div – 10 V/div | |

| DC Gain Accuracy | ± 3 % | |

| Vertical Resolution (A / D) | 8 bits (2 channels simultaneously) | |

| Interpolation | (sin x)/x | |

| Max Input Voltage | 300 V (DC + AC PK – PK) | |

| Probe Attenuation Factor | 1 x, 10 x, 100 x, 1000 x | |

| Trigger Mode | Edge, Video, Pulse, Alternate, Slope | |

| Acquisition Mode | Normal, Peak Detect and Average | |

| Record Length | Max 6 K points | |

| Waveform Storage | 4 waveforms | |

| Automatic Measurement | Vpp, Vavg, Vamp, Vrms, Freq, Period, Vmax, Vmin, Vtop, Vbase, Overshoot, Preshoot, Rise Time, Fall Time, Delay A→B↑, Delay A→B↓, +Width, -Width, +Duty, -Duty |

|

| Waveform Math | +, -, x, , FFT | |

| Power Supply | 100 V – 240 V, ACRMS, 50 Hz / 60 Hz, CAT II | |

| Lissajou’s Figure | Bandwidth | 60 MHz |

| Phase Difference | ±3 degrees | |

| Communication Interface | USB, Support USB Flash Disk Storage | |

| Fuse | 1 A, T grade, 250 V | |

| Dimensions | 14.57 in x 7.09 in x 4.72 in (370 mm x 180 mm x 120 mm) | |

| Weight (without package) | 4.85 lbs (2.2 kgs) | |

| Logic Analyzer – Performance Specifications | ||

| Sample Rate | 20 S/s ~ 1 GS/s | |

| Bandwidth | 100 MHz | |

| Channels | 16 | |

| Record Length | Max 4 M / channel | |

| Input Impedance | 660 kΩ 5 % // 15 ± 5 pF | |

| Trigger Mode | Edge, Bus, State, Data alignment, Data width, Distributed queue triggers | |

| Trigger Position Setting | Pre-trigger, Mid-trigger, Re-trigger | |

| Threshold Voltage | ±6 V (4 settings) | |

| Input Signal Range | ± 30 V | |

| Data Search | Available | |

| Data System | Binary, Decimal, Hex system | |

| Digital Filter | 0, 1, 2 optional | |

| Setting Storage | 10 settings | |

| USB Flash Disk Storage | Available | |

Additional Information

Applications

- Designing and Debugging

- Circuit Function Test

- Identification signals logic information

- Education and training

- Mixed signal circuit test

Standard Accessories

- Passive probe: 2, 1.2 m, 1:1 (10:1)

- Logic Analyzer measurement module

- CD: x 1 (PC link application software)

- RS-232 data line or USB data line

- Battery

- User Manual

- Power line: one, up to the standards of the country in which it is used

Introduction to the Front Panel and the User’s Interface

GAOTek mixed signal oscilloscope offers a simple front panel with distinct functions to users for their completing some basic operations, in which the knobs and function push buttons are included. The knobs have the functions similar to other oscilloscopes. The 5 buttons in the column on the right side of the display screen are menu selection buttons (defined as F1 to F5 from top to bottom respectively), through which, you can set the different options for the current menu. The other push buttons are function buttons, through which, you can enter different function menus or obtain a specific function application directly.

Front Panel

- Power on/off

- Display area

- Control (key and knob) area

- U slot

- LA signal input

- DSO signal input

- Measurement signal output

- Power and charging indication: Green light indicates AC supply and battery full charged; yellow light indicate under charging.

Control (key and knob) area

- Menu option setting: F1 ~ F5

- Switch :

Switch includes two keys and one knob. Press “OSC/LA” to switch between Digital Signal Oscilloscope and Logic Analyzer.

For DSO “cursor” knob and “info” key are idle. But the “cursor” knob takes effect in magnifying or minifying the waveform after FFT operation when the mode is FFT.

For Logic Analyzer, “cursor” knob to adjust current cursor position and “info” key to loading setting info for acquired waveform and current waveform - Function key area

- Vertical control area:

It includes 3 keys and 4 knobs.

For DSO: “CH1 menu” and “CH2 menu” correspond to setting menu in CH1 and CH2, “Wave Math” key refer to math menu, the math menu consists of six kinds of operations, including CH1-CH2, CH2-CH1, CH1+CH2 ,CH1*CH2,CH1/CH2 and FFT. Two “Vertical position” knobs control the vertical position of CH1.CH2 and two “Volts / Div” knob control voltage scale of CH1, CH2.

For LA, “CH1 menu”, “CH2 menu”, “Wave math” keys and “CH2 Volts / Div” knob are idle. “CH1 Vertical”, “CH2 Vertical” to adjust the M1, M2 position in Cursor menu when cursor display is on “CH1 Volts/Div”. - Horizontal control area with 2 knob and 1 key:

For DSO, “Horizontal position” knob control trigger position, “Volts/Div” control time base, “Horizontal menu” key refer to horizontal system setting menu.

For LA, “Horizontal menu” key is idle. “Horizontal position” knob to adjust the position of value displayed currently quickly. “Sec/Div” knob to adjust value resolution displayed currently. - Trigger control area with 4 keys and 1 knob

Digital Storage Oscilloscope

User interface introduction

The Trigger State indicates the following information:

Auto: The oscilloscope is under the Automatic mode and is collecting the waveform under the non-trigger state.

Trig’ d: The oscilloscope has already detected a trigger signal and is collecting the after-triggering information.

Ready: All pre-triggered data have been captured and the oscilloscope has been already ready for accepting a trigger.

Scan: The oscilloscope captures and displays the waveform data continuously in the scan mode.

Stop: The oscilloscope has already stopped the waveform data acquisition.

- Waveform Viewing Area.

- The purple pointer indicates the horizontal trigger position, which can be adjusted by the horizontal position control knob.

- The pointer indicates the trigger position in the internal memory.

- This reading shows the time deviation between the horizontal trigger position and the window centre line, which is regarded as 0 in the window centre.

- It indicates the current function menu.

- It indicates the operation options for the current function menu, which changes with the function menus.

- The purple pointer shows the trigger level position.

- The reading shows the trigger level value.

- The reading shows the trigger source.

- It shows the selected trigger type:

Rising edge triggering

Rising edge triggering

Falling edge triggering

Falling edge triggering

Video line synchronous triggering

Video line synchronous triggering

Video field synchronous triggering

Video field synchronous triggering

- The reading shows the window time base set value.

- The reading shows the main time base set value.

- The two yellow dotted lines indicate the size of the viewing expanded window.

- The icon shows the coupling mode of the CH2 channel.

” — ” indicates the direct current coupling

” ~ ” indicates the AC coupling

” ” indicates GND coupling.

” indicates GND coupling.

- The reading shows the vertical scale factor (the Voltage Division) of the CH2 channel.

- The icon indicates the coupling mode of the CH1 channel: The icon “–” indicates the direct current coupling. The icon “~” indicates the AC coupling .The icon “

” indicates GND coupling.

” indicates GND coupling. - The reading indicates the vertical scale factor (the Voltage Division) of the CH1 channel.

- The information shows the zero point positions of CH1 or CH2 channel.

- The yellow pointer shows the grounding datum point (zero point position) of the waveform of the CH2 channel. If the pointer is not displayed, it shows that this channel is not opened.

- The red pointer indicates the grounding datum point (zero point position) of the waveform of the CH1 channel. If the pointer is not displayed, it shows that the channel is not opened.

- The positions of two purple dotted line cursors measurements.

- The reading shows the frequency of the two channels. It is a 6 digits cymometer. Its measurement range of frequency is 2Hz to full bandwidth. When the triggering mode is edge triggering, it is a one channel cymometer and it can only measure the frequency of the triggering channel. When the triggering mode is alternating triggering, it is a two channel cymometer and it can measure the frequency of two channels.

How to implement the Function Inspection

Make a fast function check to verify the normal operation of the instrument, according to the following steps:

- Connect the Instrument to the Power and Push down the Power Switch Button.

The instrument carries out all self-check items and shows the prompt “Press any Key Enter system“. Press the “8 (UTILITY)” button to get access to the “FUNCTION” menu and push down F2 the menu selection button to call out the function “Recall Factory”. The default attenuation coefficient set value of the probe in the menu is 10X, - Set the Switch in the Oscilloscope Probe as 10X and Connect the Oscilloscope with CH1 Channel.

Align the slot in the probe with the plug in the CH1 connector BNC, and then tighten the probe with rotating it to the right side.

Connect the probe tip and the ground clamp to the connector of the probe compensator. - Press the “7(AUTOSET)”

The square wave of 1 KHz frequency and 5 V peak-peak value will be displayed in several seconds (as shown below)

Check CH2 by repeating Step 2 and Step 3

How to Implement the Probe Compensation

For adjusting the probe compensation, please carry out the following steps:

- Set the attenuation coefficient of the probe in the menu as 10 X and that of the switch in the probe as 10 X, and connect the oscilloscope probe with the CH1 channel. If a probe hook tip is used, ensure that it keeps in close touch with the probe. Connect the probe tip with the signal connector of the probe compensator and connect the reference wire clamp with the ground wire connector of the probe connector, and then press the button “7(AUTOSET)”.

- Check the displayed wave forms and regulate the probe till a correct compensation is achieved (see the figures below)

Displayed Wave Forms of the Probe Compensation

- Repeat the steps mentioned if necessary

Adjust Probe

- How to Set the Probe Attenuation Coefficient The probe has several attenuation coefficients, which will influence the vertical scale factor of the oscilloscope. If it is required to change (check) the set value of the probe attenuation coefficient, press the function menu button of the channels used, then push down the selection button corresponding to the probe till the correct set value is shown. This setting will be valid all the time before it is changed again.

Note: The attenuation coefficient of the probe in the menu is pre-set to 10X when the oscilloscope is delivered from the factory.

Make sure that the set value of the attenuation switch in the probe is the same as the menu selection of the probe in the oscilloscope.The set values of the probe switch are 1 X and 10 X (see fig. below).

Note: When the attenuation switch is set to 1 X, the probe will limit the bandwidth of the oscilloscope in 5MHz. If it is needed to use the whole bandwidth of the oscilloscope, the switch must be set to 10 X.

How to set Utility

Utility function includes recall factory, Language, Carry.

Utility menu as below

| Function | Setting | Instruction |

| Recall factory | Default setting for LA | |

| Language | English

… |

Support multi-languages, choose you preferred system language. |

| Carry | Vector

BMP |

Set data format to be vector and loading data display with “Bin” format

Set data format to be BMP and loading data display with “BMP” format. |

Troubleshooting

In case the oscilloscope is still in the black-screen state without any display after the power is switch on, implement the following fault treatment procedure.

- Check whether the power connection is connected properly.

- Check whether the power switch is pushed down to the designated position.

- Restart the instrument after completing the checks above.

- If this product still cannot work normally, please get in touch with Lilliput and we will be under your service.

After acquiring the signal, carry out the following operations if the wave form of the signal is not displayed in the screen.

- Check whether the probe is properly connected to the signal connecting wire.

- Check whether the signal connecting wire is correctly connected to the BNC (namely, the channel connector).

- Check whether the probe is properly connected with the object to be measured.

- Check whether there is any signal generated from the object to be measured (the trouble can be shot by the connection of the channel from which there is a signal generated with the channel in fault).

- Make the signal acquisition operation again.

The measured voltage amplitude value is 10 times greater or smaller than the actual value.

- Check whether the channel attenuation coefficient and the attenuation ration of the probe used in practical application is match.

There is wave form displayed, but it is not stable.

- Check whether the Source item in the TRIG MODE menu is in conformity with the signal channel used in the practical application.

- Check on the trigger Type item: The common signal chooses the Edge trigger mode for Type and the video signal the Video. Only if a proper trigger mode is applied, the wave form can be displayed steadily.

- Try to change the trigger coupling into the high frequency suppress and the low frequency suppress to smooth the high frequency or low frequency noise triggered by the interference.

No Display Responses to the Push-down of RUN/STOP.

- Check whether Normal or Signal is chosen for Polarity in the TRIG MODE menu and the trigger level exceeds the wave form range.

- If it is, make the trigger level is centered in the screen or set the trigger mode as Auto. In addition, with the AUTOSET button pressed, the above settings can be completed automatically.

After the AVERAGE value sampling is set in the ACQU MODE or the longer duration is set in the DISP MODE, the display rate is slowed down.It is a normal phenomenon.

Maintenance, Cleaning and Repairing

General Maintenance

Please do not store or keep the instrument in the place where the liquid crystal display will be directly exposed to the sunlight for a long time.

Caution: The instrument or probe should not be stained with the spraying agent, liquid and solvent to avoid any damage to it.

Cleaning:

Check the probe and instrument regularly according to their operating state. Clean the external surface of the instrument following the steps shown below:

- Please wipe the dust from the instrument and probe surface with a soft cloth. Do not make any scuffing on the transparent LCD projection screen when cleaning the LCD screen.

- Clean the instrument with a wet soft cloth, please pay attention to the disconnection of power. It is recommended to scrub with soft detergent or fresh water. Please don’t apply any corrosive chemical cleaning agent to prevent the instrument or probe from damage.

Warning: Before power on for operation, it is required to confirm that the instrument has already been dried completely, avoiding any electrical short circuit or bodily injury resulting from the moisture.