Description

Overview

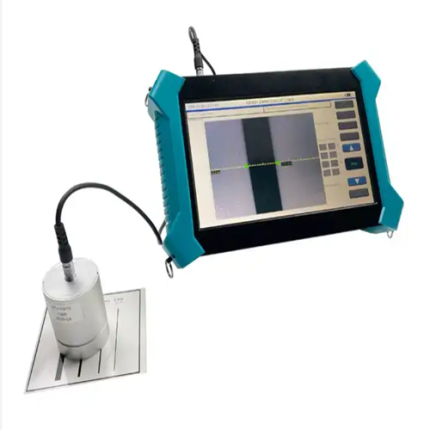

GAOTek non destructive flaw detector is a virtual instrument: wire rope infinite uncertainty. Only the application of virtual instrument technology, replacing the traditional instruments with software, directly sampled and processed by the computer, so as not to miss, not false, like watching movies, full scan of the steel wire rope, the result is accurate, repeatable. Three instruments: according to the regulations of wire rope in different sectors of the scrapping of the national standards, the product application of qualitative, quantitative, electromagnetic positioning, online nondestructive testing of wire rope broken wires, internal and external corrosion, abrasion, metallic cross-sectional area changes, loose strands, jump wire, deformation, material anomalies such as defects. The 3 legal instruments: according to the regulations of the state measurement and the state production safety law, each instrument by the national metrology institutes, according to American standards and Shanghai enterprise standards as the third party inspection, and issue the test report, obtain legal qualification.

Features

- High resolution display

- Precise detection capabilities

- User-friendly interface

- Advanced pulser technology

- Digital signal processing

- Internal data logger

- Gage View interface program

- Test block and couplet

- USB Cable

Technical specifications

| Qualitative wire detection | 99.99 % |

| diameter | 0.87 in to 23 in ( 8 mm to 44 mm) |

| Environment temperature | 14 ° F to 131° F (-10℃ to 50℃) |

| Sensor weight | 7.9 lb (10 kg) |

| Power supply | 5 V |

| Position (L) detection capability | +0.2% |

| The sensitivity of detection repeatability error | ±0.055% |

| Power | Built-in lithium battery |

| size | 11.81 in x 18.11 in x 19.69 in (30 cm x 46 cm x 50 cm) |