Description

Overview

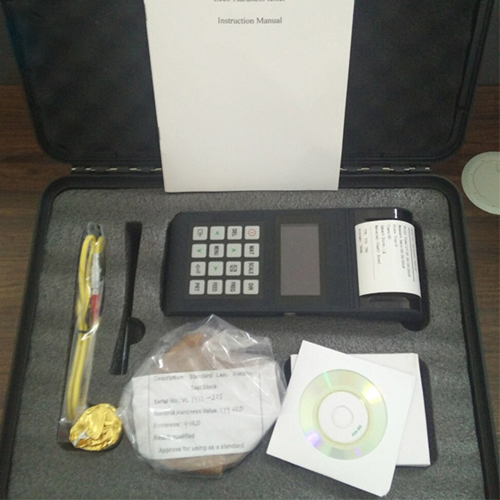

GAOTek portable hardness tester is developed Leeb hardness measurement principle based on the internationally popular metal material hardness tester. It has high accuracy, small size, easy to operate, and a wide range of measurement, especially for large, heavy-duty malleable pieces, example: roll turbine shaft, and applied to the components already installed and cannot be demolished, for example, site hardness testing of pressure vessels, turbine units and other equipment. Leeb hardness tester is widely used in petrochemical, aerospace, electric power, gas, automotive, shipbuilding, railways, machinery manufacturing and other industries.

Features

- Based on the principle of measuring the Leeb hardness, it can be measured in a variety of metal materials

- Easily switch to the hardness of all formats (HL, HB, HRB, HRC, HRA, HV, HS) parallel conversion of the measured value of the hardness

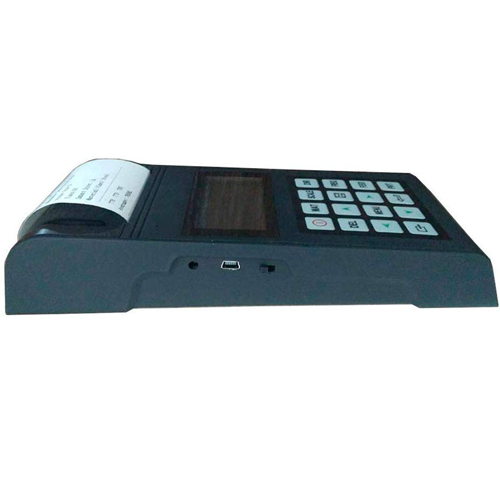

- Using the big screen 128 in x 64 in graphics dot matrix LCD display, information is rich, intuitive

- With bright backlight display, easy to use in the light gray environment

- A host can be equipped with 7 kinds of different impact devices

- Automatic identification of impact device type

Technical Specifications

| Hardness Scale | Richter (HL), Brinell (HB), Rockwell B / C (HRB / C), Rockwell A (HRA), the Victoria’s (HV), Shaw (HS) |

| Measuring Direction | Universal 360 degree |

| Display | Dot matrix LCD, 128 x 64 graphic dot, with backlight |

| Memory | 500 groups data can be stored and re-readable |

| Operating voltage | 6 V NiMH battery pack |

| Charging power supply | 9 V/ 500 mA |

| Charging time | 2.5 hrs to 3.5 hrs |

| Continuous working | About 150 hrs |

| Relative Humidity | ≤ 90% |

| Operating temperature | 14 °F to 122 °F (-10 °C to 50 °C) |

| Storage Temperature | -22 °F to 140 °F (-30 °C to 60 °C) |

| Paper width | 2.26 in ± 0.01 in (57.5 mm ± 0.5 mm) |

| Print Roll Diameter | 1.18 in (30 mm) |