Description

Overview

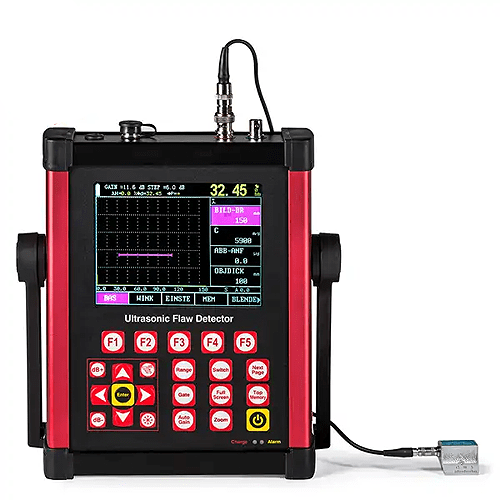

GAOTek Ultrasonic Flaw/Crack Detector is for quickly and accurately detection, positioning, evaluation and diagnosis of various flaws in the workpiece, such as cracks, welds, blowhole, etc. Widely used in electric power, petrochemical, boiler and pressure vessel, steel, military, aerospace, railway transportation, automobiles, machinery, and etc.

Technical Specifications

| Operating Frequency | 0.5 MHz to 20 MHz |

| Scan Range | 0 in to 393.7 in (0 mm to 10000 mm) |

| Velocity Range | 39,370 in/s to 787,401.57 in/s(1000 m/s to 20000 m/s) |

| Vertical linearity error | ≤ 2% |

| Dynamic Range | ≥ 35 dB |

| Horizontal linearity error | ≤ 0.1% |

| Testing sensitivity | ≥ 65 dB (Depth 7.87 in (200mm), Φ2 flat bottom hole) |

| Measuring channel | 500 |

| Storage | 1000 |

| TCG curve | x |

| B Scan | x |

| Gain Range | 0 dB to 130 dB |

| AWS | x |

| Standard Probes | Straight probe: 2.5 MHz, diameter 0.79 in (20 mm), cable Q9Angle probe: 4 MHz, 60 degrees, 0.31 in x 0.35 in (8 mm x 9 mm), cable Q9 to C5 |

| Dimension | 9.45 in x 7.28 in x 2.17 in(240 mm × 185 mm × 55 mm) |

| Weight | 4.08 lb. (1.85 kg) |