Description

Overview

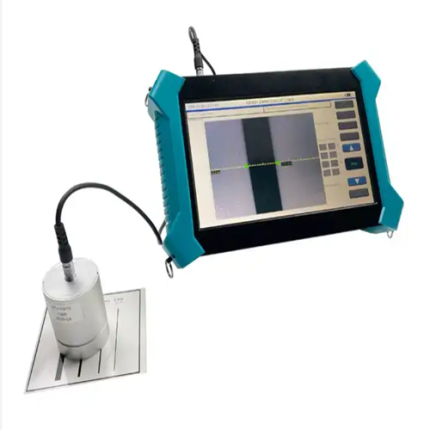

GAOTek ultrasonic welding crack flaw detector, an essential tool in the realm of non-destructive testing (NDT), plays a pivotal role in assessing the integrity of metal components, particularly in welding applications. This highly specialized device utilizes ultrasonic testing principles to probe the internal structure of metals, effectively identifying flaws and defects, including cracks, voids, and discontinuities, without causing any harm to the material. These flaw detectors are widely utilized in various industries, such as aerospace, automotive, construction, and manufacturing, where the reliability and safety of metal components are paramount.

Features

- HD color Screen

- Ultra Low Power Consumption

- Automatic Report Generation

- Strong Performance

- Audible Alarm

- Designed for thin workpiece

- Real time A-scan with adjustable gain

- Though coating measurement

- The net thickness of the substrate can be measured without removing paintings

- Unique multiple-wave verify mode

Technical Specification

| Weight | 0.55 lb (250 g) including batteries |

| Working Temperature | 14 °F to 122 °F (31 ℃ to 104 ℃) |

| Display | 2.4 in QVGA true color OLED screen, contrast 10000:1 |

| Update Rate | Selectable 4 Hz, 8 Hz, 16 Hz |

| Material Velocity Range | 0.02 in/s to 0.39 in/s (500 m/s to 9999 m/s) |

| LCD display | Led display |

| Testing Range | 0.0 in to 0.003 in (0 cm to 1500 cm) |

| Working Frequency | 0.5 MHz to 20 MHz |

| Gain | 110 dB |

| Reject | 80 % |

| Probe Type | Single Dual, Through, Immersion type |

Click Here to Download Technical

Documentation (User Manual or Instruction Manual)