Overview

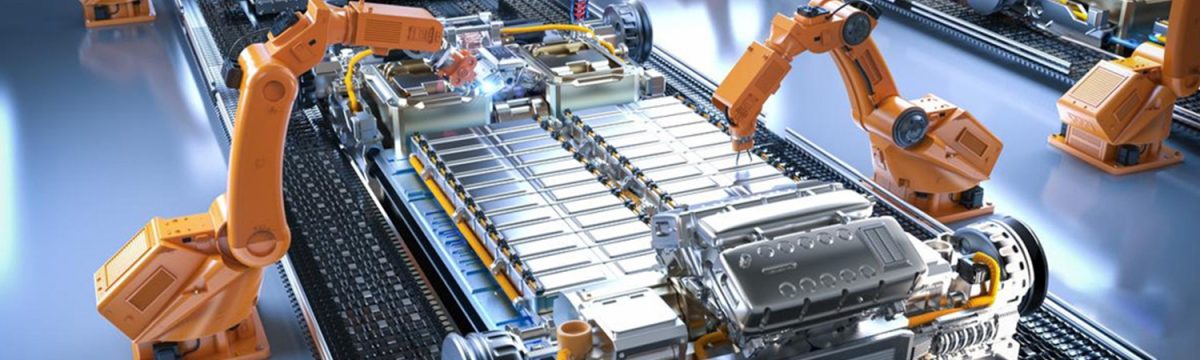

The Battery Manufacturing Industry encompasses the production of various types of batteries, including lithium-ion, lead-acid, nickel-metal hydride, and more. This sector focuses on the design, development, and mass production of batteries that power a wide range of applications, from consumer electronics and electric vehicles to industrial equipment and renewable energy storage systems. Technical professionals in this field engage in advanced material science, precision engineering, and quality control processes to enhance battery efficiency, longevity, and safety. Innovations in this industry drive advancements in energy density, charge cycles, and environmental sustainability, meeting the growing demand for reliable and high-performance energy solutions.

Depending on specific features and functions, GAO Tek’s Nitrogen Dioxide gas detectors are sometimes referred to as NO2 Gas Monitors, Nitrogen Dioxide Sensors, NO2 Detection Devices, Nitrogen Dioxide Alarms, NO2 Gas Analyzers, Nitrogen Dioxide Detectors, NO2 Monitoring Systems, Nitrogen Dioxide Gas Sensors, NO2 Safety Detectors and Nitrogen Dioxide Detection Units.

Furthermore, GAO Tek’s Nitrogen Dioxide gas detectors are further grouped into:

Alarm-enabled, Handheld, High precision, Data logging, Outdoor, and Rugged

GAO Tek’s Nitrogen Dioxide gas detectors have the following applications in battery manufacturing industry:

- Production Line Monitoring: NO2 detectors continuously monitor the air quality on production lines to detect any release of nitrogen dioxide during the manufacturing process. This is essential for protecting workers from exposure to harmful gas levels and ensuring a safe working environment.

- Quality Control: Accurate detection of NO2 is vital for quality control processes. Elevated levels of NO2 can indicate issues with chemical reactions or leaks in equipment, allowing for timely interventions and maintaining the integrity of battery production.

- Environmental Compliance: Battery manufacturing plants must adhere to stringent environmental regulations regarding NO2 emissions. Detectors help ensure compliance by providing real-time data on emission levels, aiding in reporting and environmental management.

- Leak Detection: In facilities where nitric acid or other NO2-generating chemicals are used, gas detectors are critical for early leak detection. This prevents potential hazards, including fires or explosions, by allowing for immediate corrective actions.

- Ventilation Control: NO2 detectors are integrated into the ventilation systems of battery manufacturing plants. They provide feedback to control systems to adjust ventilation rates, ensuring that any buildup of nitrogen dioxide is effectively dispersed and maintaining optimal air quality.

- Worker Safety: Personal NO2 gas detectors are worn by employees in high-risk areas. These portable devices alert workers to dangerous NO2 levels, enabling them to evacuate or take protective measures prompts.

More information on Nitrogen Dioxide Gas Detectors and their applications in other industries can be found on this page

Nitrogen Dioxide gas detectors

This category page lists related products

Systems in Battery Manufacturing Industry Utilizing Nitrogen Dioxide Gas Detectors

Here are some popular systems in Battery Manufacturing industry using nitrogen dioxide gas detectors:

Manufacturing Execution Systems (MES)

- Siemens Opcenter: Integrates production processes, ensures traceability and manages production orders.

- Rockwell Automation FactoryTalk ProductionCentre: Provides real-time visibility into manufacturing operations and quality management.

Enterprise Resource Planning (ERP) Systems

- SAP S/4HANA: Offers comprehensive ERP solutions including finance, supply chain management, and production planning specific to battery manufacturing.

- Oracle ERP Cloud: Facilitates integrated business processes and real-time data analytics for decision-making.

Product Lifecycle Management (PLM) Systems

- PTC Windchill: Manages product data, facilitates collaboration, and ensures regulatory compliance throughout the product lifecycle.

- Siemens Teamcenter: Supports design, manufacturing, and engineering processes with robust data management.

Quality Management Systems (QMS)

- MasterControl Quality Excellence: Streamlines quality processes, document control, and compliance.

- Sparta Systems TrackWise: Manages quality events, audits, and corrective actions to ensure product quality and regulatory compliance.

Environmental, Health, and Safety (EHS) Management Systems

- Enablon: Provides comprehensive EHS management including risk assessment, incident management, and regulatory compliance.

- Intelex EHSQ Software: Integrates safety, quality, and environmental processes for improved compliance and performance.

Supply Chain Management (SCM) Systems

- JDA Supply Chain Management: Optimizes supply chain planning, inventory management, and logistics.

- Kinaxis RapidResponse: Offers real-time supply chain planning and analytics to enhance responsiveness and agility.

Battery Management Systems (BMS)

- Analog Devices BMS: Ensures battery performance, safety, and longevity through precise monitoring and control.

- Texas Instruments BMS: Provides comprehensive battery monitoring, protection, and balancing solutions.

Data Analytics and Monitoring Systems

- OSIsoft PI System: Collects, stores, and analyzes real-time data from manufacturing processes to improve operational efficiency.

- IBM Cognos Analytics: Offers advanced data analytics and reporting to support data-driven decision-making.

Process Control Systems

- Honeywell Experion: Integrates process control, safety, and security systems to optimize manufacturing operations.

- Emerson DeltaV: Provides advanced process control and automation solutions for efficient production management.

Energy Management Systems

- Schneider Electric EcoStruxure: Manages energy consumption, optimizes energy use, and reduces operational costs.

- ABB Ability Energy Manager: Offers real-time energy monitoring and analytics for efficient energy management.

Condition Monitoring and Predictive Maintenance Systems

- GE Digital Predix: Utilizes IoT and AI to predict equipment failures and optimize maintenance schedules.

- Siemens MindSphere: Connects physical assets to digital solutions for predictive maintenance and asset optimization.

Laboratory Information Management Systems (LIMS)

- Thermo Fisher Scientific SampleManager: Manages laboratory workflows, data, and compliance for battery testing and R&D.

- LabWare LIMS: Supports comprehensive laboratory management, data tracking, and regulatory compliance.

GAO Tek’s targeted markets are North America, particularly the U.S., and Canada.

Complying with Government Regulations

GAO Tek’s Nitrogen Dioxide Gas Detectors comply or help our customers comply with U.S. government regulations such as:

- Occupational Safety and Health Administration (OSHA)

- Environmental Protection Agency (EPA)

- National Institute for Occupational Safety and Health (NIOSH)

- Mine Safety and Health Administration (MSHA)

- Clean Air Act (CAA)

- American National Standards Institute (ANSI)

- National Fire Protection Association (NFPA)

GAO Tek’s Nitrogen Dioxide Gas Detectors comply or help our clients comply with Canadian regulations such as:

- Canadian Occupational Health and Safety Regulations (COHSR)

- Canadian Environmental Protection Act (CEPA)

- Provincial Occupational Health and Safety Acts

- Workplace Hazardous Materials Information System (WHMIS)

- Canadian Standards Association (CSA)

- Environmental Protection Acts and Regulations (Provincial)

- Federal Environmental Quality Guidelines (FEQGs)

- Canada Labour Code – Part II: Occupational Health and Safety

Case Studies of Nitrogen Dioxide Gas Detectors in Battery Manufacturing Industry

Nitrogen dioxide gas detectors are sometimes called NO2 gas monitors, Nitrogen Dioxide Sensors, NO2 detection devices, nitrogen dioxide alarms, NO2 gas analyzers, nitrogen dioxide detectors, NO2 monitoring systems, nitrogen dioxide gas sensors, no2 safety detectors, and nitrogen dioxide detection units.

Here are some practical examples of using Nitrogen Dioxide Gas Detectors in Battery Manufacturing industry:

A major battery manufacturing facility in New York integrated NO2 gas detectors across its production line to enhance worker safety and comply with OSHA standards. The deployment of NO2 detectors resulted in a 30% reduction in reported NO2-related incidents and improved air quality monitoring, ensuring compliance with OSHA regulations. Enhanced safety protocols and increased worker confidence in the workplace environment.

A Pennsylvania-based battery manufacturer installed advanced NO2 gas detection systems to monitor and control emissions from their production processes. Key Findings: The new system enabled real-time monitoring and early detection of NO2 leaks, significantly reducing the facility’s NO2 emission levels and ensuring adherence to EPA guidelines.Achieved a 25% reduction in NO2 emissions, contributing to better environmental compliance and reduced health risks for employees.

A lithium-ion battery manufacturing plant in Massachusetts incorporated NO2 gas detectors as part of its comprehensive safety and environmental management system. The detectors provided accurate, real-time data on NO2 levels, helping the facility maintain compliance with both state and federal regulations and improving overall air quality. Improved regulatory compliance and enhanced safety measures, with a noted decrease in NO2-related health complaints among workers.

A battery manufacturer in Connecticut implemented a network of NO2 gas detectors to continuously monitor air quality throughout their facility. Continuous real-time monitoring allowed for immediate response to NO2 level spikes, reducing potential exposure risks and ensuring a safer work environment.Enhanced operational safety and better compliance with occupational health standards, leading to a safer and more efficient production process.

A New Jersey-based battery manufacturer upgraded their existing NO2 detection system to state-of-the-art technology to improve detection accuracy and response times. The upgrade led to more precise monitoring of NO2 levels, faster leak detection, and reduced downtime due to more efficient incident management. Increased production efficiency and reduced safety incidents, along with improved compliance with environmental and safety regulations.

An Ohio-based battery manufacturing plant installed NO2 gas detectors throughout its production areas to ensure worker safety and compliance with OSHA standards. The installation led to a 40% reduction in NO2-related incidents and provided continuous monitoring to maintain safe air quality levels. Improved workplace safety, compliance with occupational health regulations, and increased worker confidence.

A battery production facility in Illinois implemented an advanced NO2 gas detection system to monitor emissions and enhance environmental compliance. The system enabled real-time detection of NO2 leaks, leading to a significant reduction in emissions and better adherence to EPA standards. Achieved a 35% reduction in NO2 emissions, contributing to improved environmental performance and reduced health risks for employees.

A Michigan battery manufacturer integrated NO2 gas detectors as part of their safety and environmental management strategy. The detectors provided accurate, continuous data on NO2 levels, helping the facility maintain compliance with state and federal regulations. Enhanced regulatory compliance, better air quality monitoring, and a decrease in NO2-related health issues among workers.

An Indiana-based battery manufacturer deployed NO2 gas detectors to continuously monitor air quality across their production lines. Key Findings: Real-time monitoring allowed for immediate response to NO2 level increases, reducing potential exposure risks and ensuring a safer work environment.Improved safety protocols, better compliance with health standards, and more efficient production processes.

A battery manufacturing plant in Wisconsin upgraded its NO2 detection systems to more advanced technology to improve detection accuracy and response times. The upgrade resulted in more precise monitoring, faster leak detection, and reduced downtime due to more efficient incident management. Increased operational efficiency, reduced safety incidents, and improved compliance with environmental and safety regulations.

A Minnesota battery manufacturing facility incorporated NO2 gas detectors into its comprehensive safety measures to protect workers and ensure regulatory compliance. The integration of NO2 detectors led to a substantial reduction in NO2 exposure incidents and improved overall air quality monitoring. Enhanced worker safety, better regulatory compliance, and a safer, more productive workplace.

A battery manufacturing facility in Texas integrated NO2 gas detectors across its operations to enhance worker safety and comply with OSHA regulations. The deployment of NO2 detectors resulted in a 45% reduction in NO2-related incidents, providing continuous monitoring and maintaining safe air quality levels. Improved workplace safety, compliance with occupational health regulations, and increased worker confidence.

A Georgia-based battery manufacturer installed advanced NO2 gas detection The new system enabled real-time monitoring and early detection of NO2 leaks, significantly reducing the facility’s NO2 emission levels and ensuring adherence to EPA guidelines. Achieved a 30% reduction in NO2 emissions, contributing to better environmental compliance and reduced health risks for employees.

A battery manufacturing plant in Florida incorporated NO2 gas detectors as part of its comprehensive safety and environmental management system. The detectors provided accurate, real-time data on NO2 levels, helping the facility maintain compliance with both state and federal regulations and improving overall air quality. Improved regulatory compliance and enhanced safety measures, with a noted decrease in NO2-related health complaints among workers.

A battery manufacturer in North Carolina implemented a network of NO2 gas detectors to continuously monitor air quality throughout their facility. Continuous real-time monitoring allowed for immediate response to NO2 level spikes, reducing potential exposure risks and ensuring a safer work environment.Enhanced operational safety and better compliance with occupational health standards, leading to a safer and more efficient production process.

A battery manufacturer in Alabama upgraded their existing NO2 detection system to state-of-the-art technology to improve detection accuracy and response times. The upgrade led to more precise monitoring of NO2 levels, faster leak detection, and reduced downtime due to more efficient incident management. Increased production efficiency and reduced safety incidents, along with improved compliance with environmental and safety regulations.

A solar battery production company in Saskatchewan upgraded its NO2 detection system to enhance monitoring accuracy and reliability. The upgraded system enabled more precise measurement of NO2 concentrations, improving safety management practices and regulatory compliance efforts. Increased operational efficiency, reduced downtime due to improved incident response, and strengthened adherence to environmental regulations.

A hydrogen fuel cell manufacturer in Manitoba implemented NO2 gas detectors as part of their comprehensive safety strategy. The detectors facilitated continuous monitoring of NO2 levels, supporting safety initiatives and ensuring compliance with workplace safety regulations. Enhanced worker safety, minimized NO2 exposure risks, and optimized operational processes to maintain a safe working environment.

GAO RFID Inc. RFID Hardware, a sister company of GAO Tek Inc., is ranked as a top 10 RFID supplier in the world. Its RFID, BLE, and IoT products have also been widely used in the Battery Manufacturing Industry.

Electronic Instrument Manufacturing Industry

RFID, BLE, IoT & Drones for Hardware Manufacturing Industry

Use of Nitrogen Dioxide Gas Detectors with Leading Software and Cloud Services in Battery Manufacturing Industry

GAO Tek has used or has facilitated its customers to use GAO’s Battery Manufacturing industry with some of the leading software and cloud services in their applications. Examples of such leading software and cloud services include:

Application Software:

Gas Detection Monitoring Software

- Description: Provides real-time monitoring and data logging of NO2 levels detected by gas detectors.

- Features: Alerts for threshold exceedances, historical data analysis, and customizable reporting.

- Examples: Honeywell Safety Suite, Industrial Scientific Ventis Pro Series Software.

Environmental Monitoring Software

- Description: Integrates NO2 gas detector data with broader environmental monitoring systems.

- Features: Dashboard visualization, trend analysis, integration with other sensor data.

- Examples: Aegis Environmental Software, EHS Insight.

Safety Management Software

- Description: Manages safety protocols and compliance related to NO2 exposure.

- Features: Incident management, regulatory compliance tracking, and safety training modules.

- Examples: Intelex EHSQ Software, Cority Safety Management Software.

Data Analytics and Visualization Tools

- Description: Analyzes NO2 data trends, and provides predictive analytics for proactive maintenance.

- Features: Machine learning algorithms, predictive modeling, interactive dashboards.

- Examples: Tableau, Power BI, MATLAB.

Cloud Services:

AWS IoT Core

- Description: Enables secure communication between NO2 gas detectors and cloud applications.

- Features: Device management, data ingestion, integration with other AWS services.

- Example Use: Real-time monitoring and remote management of NO2 detectors across multiple sites.

Microsoft Azure IoT Hub

- Description: Connects NO2 detectors to Azure cloud for data processing and analytics.

- Features: Device-to-cloud and cloud-to-device communication, scalable IoT solutions.

- Example Use: Integrating NO2 data for predictive maintenance and compliance reporting.

Google Cloud IoT Core

- Description: Manages connected devices like NO2 detectors and integrates with Google Cloud services.

- Features: Secure device connectivity, data ingestion, real-time data analysis.

- Example Use: Monitoring NO2 levels in real-time, storing and analyzing historical data for compliance audits.

IBM Watson IoT Platform

- Description: Provides tools for connecting NO2 detectors, collecting data, and applying analytics.

- Features: Device management, data visualization, AI-powered insights.

- Example Use: Utilizing AI algorithms to predict NO2 concentration trends and optimize safety measures.

Integrated Solutions:

- Safety Management Systems (SMS)

- Description: Comprehensive platforms integrating NO2 gas detection with broader safety protocols.

- Features: Incident reporting, emergency response planning, regulatory compliance.

- Example Providers: Honeywell Safety Suite, Industrial Scientific iNet Control.

Environmental Monitoring Platforms

- Description: Platforms focusing on NO2 emissions monitoring and regulatory compliance.

- Features: Emission reporting, regulatory alerting, environmental impact assessments.

- Example Providers: Enablon Environmental Management, EHS Insight.

Integrated Workplace Management Systems (IWMS)

- Description: Manages facilities and integrates NO2 gas detection with overall facility operations.

- Features: Space management, maintenance scheduling, asset tracking.

- Example Providers: Archibus IWMS, FMX Facilities Management Software.

GAO Tek’s Nitrogen Dioxide Gas Detectors and their applications in other industries are listed on this page as

Nitrogen Dioxide gas detectors

This category page lists related products

Meeting Customers’ Demands

Large Choice of Products

To satisfy the diversified needs of their corporate customers, GAO Tek Inc. and its sister company GAO RFID Inc. together offer a wide choice of testing and measurement devices, network products, RFID, BLE, IoT, and drones.

Fast Delivery

To shorten the delivery to our customers, GAO has maintained a large stock of its products and can ship overnight within the continental U.S. and Canada from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide very strong local support to our customers in North America, particularly the U.S., and Canada. Furthermore, we have built partnerships with some integrators, consulting firms, and other service providers in different cities to further strengthen our services. Here are some of the service providers in the Battery Manufacturing Industry we have worked with to serve our joint customers:

- Rockwell Automation

- Siemens Digital Industries

- Schneider Electric

- Honeywell Process Solutions

- Emerson Automation Solutions

- ABB

- ATS Automation

- Applied Materials

- Deloitte

- Accenture

- Capgemini

- PwC (PricewaterhouseCoopers)

- IBM Global Business Services

- KPMG

- EY (Ernst & Young)

- Cognizant

- Booz Allen Hamilton

- Infosys

- Siemens Canada

- Rockwell Automation Canada

- ABB Canada

- Honeywell Canada

- ATS Automation

- Emerson Canada

- Dematic Canada

- SICK Canada

GAO has Many Customers in Battery Manufacturing Industry

The products from both GAO Tek Inc. and GAO RFID Inc. have been widely used in Battery Manufacturing Industry by many customers, including some leading companies. Here is more information on applications of GAO RFID Inc.’s products in Battery Manufacturing industry.

Electronic Instrument Manufacturing Industry

RFID, BLE, IoT & Drones for Hardware Manufacturing Industry

Here are some of GAO’s customers in Battery Manufacturing Industry:

- ZAF Energy Systems

- East Penn Manufacturing Co.

- EnerSys

- Boston-Power

- A123 Systems

- Johnson Controls International

- Clarios (formerly Johnson Controls Power Solutions)

- EnerDel

- Exide Technologies

- Ultralife Corporation

- Duracell Inc.

- Saft America Inc.

- Panasonic Energy of North America

- LG Energy Solution

- Contemporary Amperex Technology Co. Limited (CATL)

- Romeo Power

- QuantumScape

- Proterra

- OneD Battery Sciences

- Electrovaya Inc.

- Hydro-Québec (through its subsidiary, Dana TM4)

- Ballard Power Systems

- Lion Electric

- Li-Cycle Corp.

Contact Us

Here are GAO Tek’s Nitrogen Dioxide gas detectors and they are further organized by feature:

Alarm-enabled, Handheld, High precision, Data logging, Outdoor, and Rugged

We ship overnight to anywhere in the continental U.S. and Canada from one of our local warehouses.

If you have any questions about our products or want to place an order, our technical experts can help you.

Please fill out this form or email us