Description

Features

- Used in different kind of industries

- The chip quality is stable

- Has a filter clutter interference

- Use the remote transmission type

- It has an intelligent integrated display

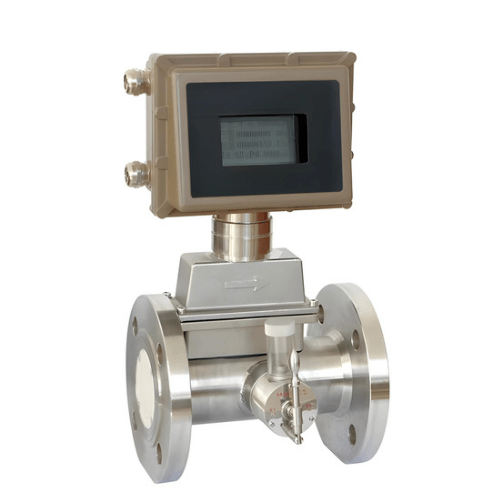

- Temperature and pressure compensation

- Has a new oil injection structure

- More stable in comparison to other types of structures

- Has the option of anti-corrosion

- Can resist to high levels of temperature

Technical Specifications

| Gauge Diameter | 20, 25, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300 |

| Accuracy Class | ± 1.5 %, ± 1.0 % (special) |

| Requirements For Straight Pipe Section | Before ≥ 2 DN, after ≥ 1 DN |

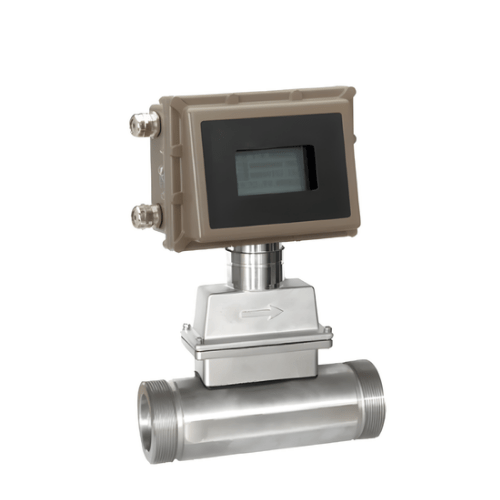

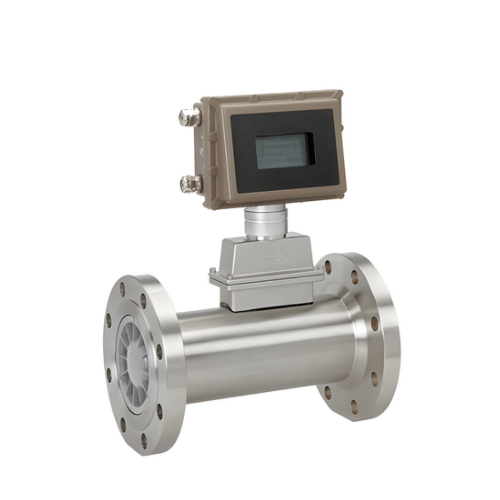

| Instrument Material | Body: 304 stainless steel Impeller: high quality aluminum alloy Converter: cast aluminum |

| Working Power Supply | A. External power supply + 24 V DC ± 15 %, suitable for 4 mA to 20 mA output, pulse output, RS485 B. Internal power supply: a set of 3.6 v 10 ah lithium battery, when the voltage is lower than 2.0, under voltage indication appears |

| Overall Power Consumption | A. External power supply: ≤ 1 W B. Internal power supply: average power consumption ≤ 1 W, can work continuously for more than three years |

| Instrument Display | Liquid crystal display, instantaneous flow, cumulative flow, temperature, and pressure can be displayed with temperature and pressure compensation |

| Signal Output | 20 mA, pulse control signal |

| Communication Output | RS485 communication |

| Signal Line Connection | Internal thread M20 × 1.5 |

| Explosion Proof Grade | ExdllCT6 |

| Protection Level | IP65 |

| Atmospheric Pressure | 86 kpa to 106 kpa |

| Relative Humidity | 5 % RH to 90 % RH |

| Medium Temperature | – 4 °F to + 176 °F (- 20 °C to + 80 °C) |

| Ambient Temperature | – 22 °F to + 149 °F (- 30 °C to + 65 °C) |