Description

Overview

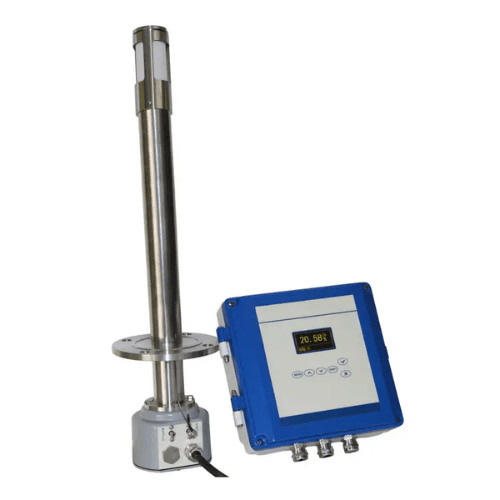

GAOTek industrial flue gas analyzer core component is a zirconia sensor. Compared with similar products on the market, it has the characteristics of high measurement accuracy, short response time, wide measurement range, high use temperature, reliable operation, easy installation, and small maintenance. Therefore, it is widely used in metallurgy, chemical industry, electric power, heating, environmental protection and other industries to analyze the oxygen content of flue gas in various industrial boilers and kilns; the control of pollutants in medical waste incinerators; the control of pollution emissions by CEMS; the steel refining Application of furnace VOD.

Technical specifications

| Test principle | Zirconia |

| Display mode | 4-digit bright LED display |

| Test range | 0.01% to 25.00% O2 |

| Accuracy | ±1.0% FS |

| Resolution | 0.01% |

| Stability | <±0.5% FS |

| Response time | T90≤20s |

| Analog output | 4 mA to 20 mA (default) or 0 mA to 20 mA or 0 mA to 24 mA. DC (non-isolated output, load resistance is less than 500Ω) 0-5V. DC (non-isolated output, load resistance greater than 10K ohm) |

| Communication interface | RS232 (default) or RS485 |

| Working power | AC220V 50 Hz or 60 Hz, power consumption ≤100W |

| Sampling method | Plug-in |

| Calibration method | Online calibration |

| Background gas | Combustion flue gas (except strong corrosion and reducing gas) |

| Hole size | Φ45 mm to Φ60 mm |

| Connection | Instrument and probe connection cable (standard 10 meters) |

| Probe length | Standard length is 0.000621371 mi (1 m) |

| Installation | Instrument: Wall-mounted Probe: plug-in, DN65 standard flange connection |

| Working temperature | Instrument: 14°F to 122°F (-10°C to +50℃) Probe: conventional type: 32°F to 392°F (0°C to 200℃) |