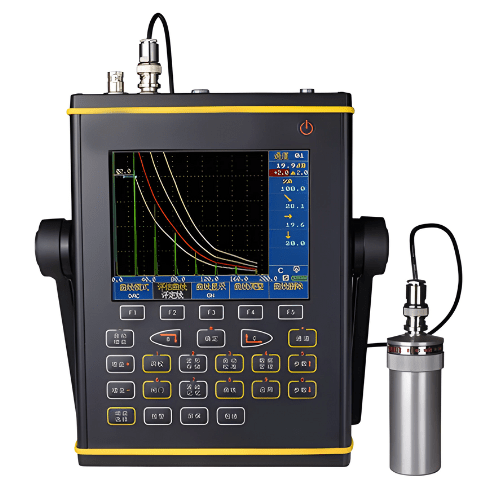

Description

Features

- Widely applicable. Capable of detecting equipment such as porcelain insulators, bushings, transformer boxes, generator bearings, etc.

- Recognized by national grid regulations. Compared with other products, the ultrasonic testing method is a mechanical testing method recognized by the State Grid regulations

- The detection rate of insulator defects can reach 100%, and it can detect internal small defects with high sensitivity, which is incomparable to other products in terms of effectiveness;

- Equipped with dedicated probes, achieving perfect matching with the surface of the test object, and quickly detecting internal defects in the equipment;

- The standard DAC curve for built-in post insulator flaw detection automatically emits an alarm when internal cracks exceed the standard, indicating internal defects

- Equipped with automatic probe correction function and curvature surface correction function

- Provide supporting upper computer software to facilitate communication with computers

Technical Specifications

| Working Frequency | 0.5 MHz to 20 MHz |

| Gain Adjustment | 110 dB (set manual 0.1dB, 2dB, 6dB steps) |

| Detection Range | 0 in to 393.7in (0 mm to 9999 mm) steel longitudinal wave |

| Vertical Error | ≤ 3% |

| Horizontal Error | ≤ 0.1% |

| Resolution | >42 dB (5P14) |

| Sensitivity | >62dB (depth 200mm Φ 2 flat bottom holes) |

| Display Screen | TFT true color display screen |

| Data Storage | Store 21 sets of flaw detection parameters and 1000 flaw detection echoes |

| Supply Voltage | The direct current (DC) 7.4V battery operates continuously for 12 hours; |

| AC 220 V | |

| Ambient Temperature | -13°F to 122°F (-25 ℃ to 50 ℃) |

| Relative Humidity | 20% to 95% RH |

| External Dimensions | 8.27 in x 6.61 in x 1.97 in (210 mm x 168 mm x 50 mm) |

| Weight | 3.97 lbs (1.8 kg) |