Overview

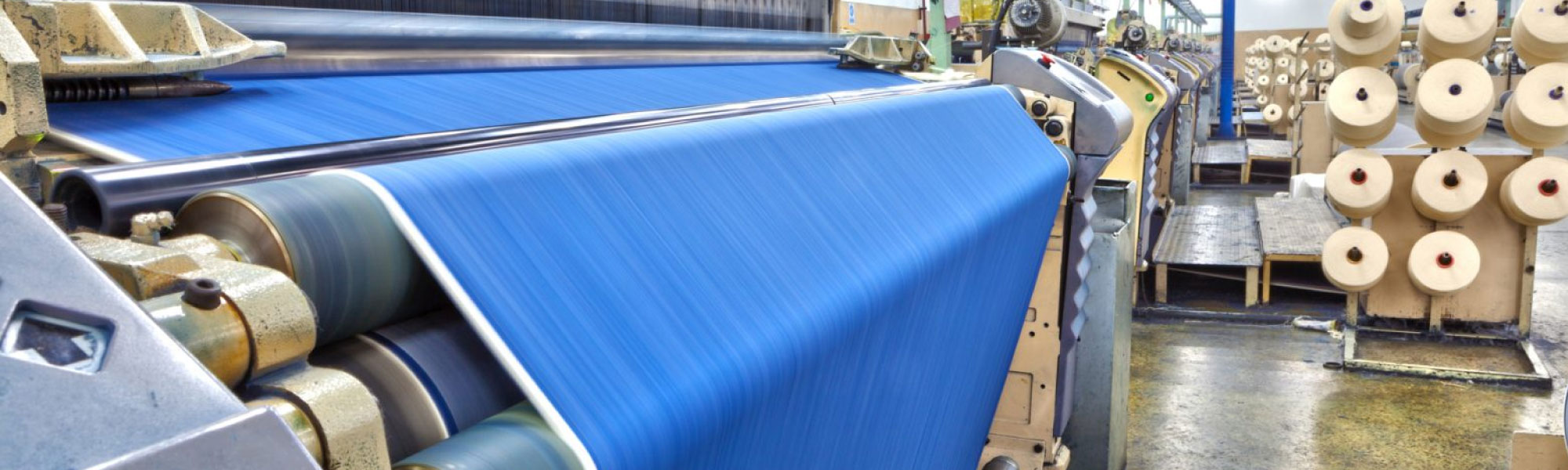

The textile industry is a sector that encompasses the production of various types of fabrics, fibers, and textiles used in clothing, home furnishings, and industrial applications. It is one of the oldest and largest industries in the world, playing a significant role in the global economy. The process of textile production involves several stages, including fiber production, spinning, weaving or knitting, dyeing or printing, and finishing.

Depending on specific features and functions, GAO Tek’s Ion meters are sometimes referred to as:

- Ion-Selective Electrodes (ISE)

- Ion-Specific Electrodes

- Ion Analyzers

- Ion Sensors

- Ion Electrodes

- ISE Meters

- Ion-Sensitive Field-Effect Transistors (ISFETs)

- Ionic Selectivity Meters

- Potentiometric Ion Meters

GAO Tek’s Ion meters have the following applications in Textile Industry:

- pH Measurement in Dye Baths: Ion meters are used to measure the pH level in dye baths during the dyeing process. Maintaining the proper pH is essential for achieving the desired color intensity and colorfastness of the dyed textiles.

- Monitoring of Salt Concentrations: Ion meters are used to monitor the concentration of salts, such as sodium chloride, in different stages of textile processing. Controlling the salt concentration is crucial for achieving consistent dyeing and finishing results.

- Water Hardness Measurement: Ion meters are used to measure the concentration of calcium and magnesium ions in water used for textile processing. Proper water hardness management ensures better performance of detergents and chemicals used in textile treatments.

- Analysis of Wastewater: Ion meters are employed to analyze the concentration of ions in textile wastewater. Monitoring the ions in wastewater helps textile manufacturers comply with environmental regulations and implement effective wastewater treatment strategies.

- Detection of Contaminants: Ion meters can detect the presence of harmful ions or heavy metals in textile materials or processes. Early detection of contaminants helps prevent quality issues and ensures the safety of the end products.

- Quality Control in Textile Finishing: Ion meters are used to measure the concentration of specific ions in finishing chemicals, such as softeners or flame retardants. Precise control of ion concentration ensures the desired properties in the finished textiles.

- Textile Printing: Ion meters are used to measure the pH and ionic balance of printing pastes used in fabric printing. Proper measurements contribute to consistent and vibrant color application on the fabric.

- Analysis of Specialty Textiles: Ion meters are used in the production of specialty textiles like technical textiles or antimicrobial textiles. They help ensure the right chemical treatment and ion balance to achieve specific functional properties.

More information on ion meters and their applications in other industries can be found on this page. Water Ion Meters This category page lists related products Chemical & Life Sciences Products

Complying with Industry Standards

GAO Tek’s Ion Meters comply or help our customers comply with the industry standards such as:

- ISO 9001: This standard sets out the criteria for a quality management system and is applicable to various industries, including textile manufacturing. It focuses on ensuring consistent product quality and customer satisfaction.

- ISO 14001: This standard specifies the requirements for an environmental management system. It helps organizations minimize their environmental impact and comply with relevant environmental regulations.

- ISO 17025: This standard specifies the general requirements for the competence of testing and calibration laboratories. It ensures that the ion meters used for testing in textile laboratories meet the necessary technical and quality standards.

- ASTM D13: This is a committee on textiles that develops standards related to various textile materials and processes. Although it does not specifically address ion meters, it may contain relevant guidelines for their use in textile testing and analysis.

- AATCC: The American Association of Textile Chemists and Colorists develops standards related to color fastness, chemical testing, and other textile-related properties. While not specific to ion meters, these standards may be relevant to their application in textile testing.

- Textile Regulation and REACH: Textile manufacturers may need to comply with specific regulations related to the use of chemicals and substances in textile processing. The REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals) is particularly important for textile companies that import or use chemical substances in the European Union.

- Oeko-Tex Standard: This is an international certification system for textiles, indicating that the textile product has been tested for harmful substances and is safe for human use.

- GOTS (Global Organic Textile Standard): This standard covers the entire production process of organic textiles, including environmental and social criteria. While not directly related to ion meters, it sets guidelines for sustainable and eco-friendly textile manufacturing.

- BCI (Better Cotton Initiative): This initiative sets standards for sustainable cotton production, including environmental and social guidelines for cotton growers and manufacturers.

- ZDHC (Zero Discharge of Hazardous Chemicals): While not specific to ion meters, this is an industry-wide program aiming to eliminate hazardous chemicals from the textile supply chain.

Complying with Government Regulations

GAO Tek’s Ion Meters comply or help our customers comply with the U.S. government regulations such as:

- Toxic Substances Control Act (TSCA)

- Occupational Safety and Health Administration (OSHA)

- Clean Water Act (CWA)

- Resource Conservation and Recovery Act (RCRA)

- Environmental Protection Agency (EPA) Regulations

- Consumer Product Safety Commission (CPSC) Regulations

- Federal Trade Commission (FTC) Textile Labeling Rules

- Flammable Fabrics Act (FFA)

- Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA)

GAO Tek’s Ion Meters comply or help our clients comply with the Canadian regulations such as:

- Hazardous Products Act (HPA) and Consumer Chemicals and Containers Regulations (CCCR)

- Canada Consumer Product Safety Act (CCPSA)

- Canada Labour Code

- Canadian Environmental Protection Act (CEPA)

- Canadian Environmental Assessment Act (CEAA)

- Health Canada Regulations

- Transportation of Dangerous Goods Act (TDGA)

Case Studies of Ion Meters in Textile Industry

Ion meters are sometimes called as:

- Ion-Selective Electrodes (ISE)

- Ion-Specific Electrodes

- Ion Analyzers

- Ion Sensors

- Ion Electrodes

- ISE Meters

- Ion-Sensitive Field-Effect Transistors (ISFETs)

- Ionic Selectivity Meters

- Potentiometric Ion Meters

Here are some practical examples of using ion meters in textile industry:

A textile dyeing facility in the Northeast uses ion meters to monitor and control the pH level in dye baths during the dyeing process. By maintaining the optimal pH, the facility achieves consistent and vibrant color results in their textile products.

A textile finishing plant in the Northeast uses ion meters to monitor the concentration of salts in finishing baths. By controlling the salt levels, the plant ensures consistent and desirable fabric properties in their finished textiles.

A textile manufacturing facility in the Northeast uses ion meters to measure the water hardness in their process water. This information helps them adjust water treatment processes and ensures better performance of chemicals used in textile treatments.

A textile company in the Northeast employs ion meters to analyze the ion concentrations in their wastewater before discharge. Compliance with environmental regulations regarding wastewater quality and ion content is essential to ensure sustainable operations.

A textile testing laboratory in the Northeast uses ion meters to detect the presence of heavy metals or other harmful ions in textile materials. Early detection helps prevent quality issues and ensures the safety of the end products.

A textile printing company in the Northeast uses ion meters to measure the pH and ionic balance of printing pastes used in fabric printing. Accurate measurements contribute to consistent and vibrant color application on the fabric.

A textile dyeing facility in the Midwest uses ion meters to monitor and control the pH levels in their dyeing processes. By maintaining precise pH levels, the facility ensures consistent and high-quality dyeing results in their textile products.

A textile mill in South Carolina was concerned about the safety of their workers. The mill used a variety of chemicals in the manufacturing process, and they wanted to make sure that the workers were not being exposed to harmful levels of these chemicals. The mill decided to use an ion meter to test the air quality in the workplace. The ion meter revealed that the air quality was within safe limits, but the mill was able to make some changes to their ventilation system to further reduce the workers’ exposure to chemicals.

A textile retailer in Mississippi was concerned about the quality of the fabric they were selling. The retailer had received a number of complaints from customers about fabric that was fading or pilling after a few washes. The retailer decided to use an ion meter to test the fabric for ionic contaminants. The ion meter revealed that the fabric was high in negative ions, which were causing the fabric to fade and pill. The retailer was able to find a new supplier of fabric that was free of ionic contaminants.

A textile manufacturer in California was experiencing problems with the quality of their finished products. The fabric was consistently coming out with a slightly stiff feel, even though they were using the same fabric and procedures as they had always used. The manufacturer decided to use an ion meter to test the water used in the finishing process. The ion meter revealed that the water was high in calcium ions, which were causing the stiffness in the fabric. The manufacturer was able to correct the problem by treating the water with a chelating agent.

A textile mill in Oregon was concerned about the safety of their workers. The mill used a variety of chemicals in the manufacturing process, and they wanted to make sure that the workers were not being exposed to harmful levels of these chemicals. The mill decided to use an ion meter to test the air quality in the workplace. The ion meter revealed that the air quality was within safe limits, but the mill was able to make some changes to their ventilation system to further reduce the workers’ exposure to chemicals.

A textile retailer in Washington was concerned about the quality of the fabric they were selling. The retailer had received a number of complaints from customers about fabric that was fading or pilling after a few washes. The retailer decided to use an ion meter to test the fabric for ionic contaminants. The ion meter revealed that the fabric was high in positive ions, which were causing the fabric to fade and pill. The retailer was able to find a new supplier of fabric that was free of ionic contaminants.

A textile manufacturer in Quebec was experiencing problems with the quality of their dyed fabric. The fabric was consistently coming out with a slight yellow tint, even though they were using the same dye lot and procedures as they had always used. The manufacturer decided to use an ion meter to test the water used in the dyeing process. The ion meter revealed that the water was high in iron ions, which were causing the yellow tint in the fabric. The manufacturer was able to correct the problem by treating the water with a chelating agent.

A textile mill in Ontario was concerned about the safety of their workers. The mill used a variety of chemicals in the manufacturing process, and they wanted to make sure that the workers were not being exposed to harmful levels of these chemicals. The mill decided to use an ion meter to test the air quality in the workplace. The ion meter revealed that the air quality was within safe limits, but the mill was able to make some changes to their ventilation system to further reduce the workers’ exposure to chemicals.

A textile retailer in British Columbia was concerned about the quality of the fabric they were selling. The retailer had received a number of complaints from customers about fabric that was fading or pilling after a few washes. The retailer decided to use an ion meter to test the fabric for ionic contaminants. The ion meter revealed that the fabric was high in negative ions, which were causing the fabric to fade and pill. The retailer was able to find a new supplier of fabric that was free of ionic contaminants.

GAO RFID Inc. a sister company of GAO Tek Inc., is ranked as a top 10 RFID supplier in the world. Chemical and Life Science Products

Its RFID, BLE, and IoT products have also been widely used in textile industry.

Use of Ion Meters with Leading Software and Cloud Services in Textile Industry

GAO Tek has used or has facilitated its customers to use GAO’s Ion meters with some of the leading software and cloud services in their applications. Examples of such leading software and cloud services include:

- Ionic Analyzer Pro

- Ion Meter Master

- Ion Meter Lite

- Ion Meter Mobile

- Ion Meter Cloud

- Thing Speak

- Google Cloud Platform

- Amazon Web Services (AWS)

- Origin

- Matlab

- Microsoft Azure

More information on ion meters and their applications in other industries can be found on this page. Water Ion Meters This category page lists related products Chemical and Life Sciences Products

GAO Has Many Customers in Textile Industry

The products from both GAO Tek Inc. and GAO RFID Inc. have been widely used in Textile Industry by many customers, including some leading companies. Here is more information on applications of GAO RFID Inc.’s products in Textile Industry.

Chemical and Life Sciences Products

Here are some of the leading companies in Textile Industry:

- Milliken & Company: A global diversified industrial company known for its innovations in textiles, chemicals, and floor covering products. Milliken is committed to sustainability and environmental stewardship.

- L. Gore & Associates: A technology-driven company that specializes in advanced materials and products. Gore is well-known for its breathable and waterproof Gore-Tex fabric used in outdoor apparel and footwear.

- DuPont: A multinational company that operates in various industries, including textiles. DuPont is a pioneer in developing high-performance fibers and materials for apparel and industrial applications.

- Berkshire Hathaway (Luthai Textile): A subsidiary of Berkshire Hathaway, Luthai Textile is a leading manufacturer of high-quality fabrics and apparel, known for its expertise in cotton and yarn-dyed fabrics.

- American Silk Mills: A luxury textile manufacturer that produces high-end silk fabrics for apparel, home furnishings, and interior design.

- Burlington Industries (International Textile Group): Part of the International Textile Group, Burlington Industries is a renowned textile manufacturer known for its performance fabrics, including those used in activewear and outerwear.

- Cone Denim (International Textile Group): Another division of the International Textile Group, Cone Denim is a leading supplier of denim fabrics to the apparel industry.

- Albany International: A global advanced textiles and materials processing company that serves various industries, including aerospace, filtration, and industrial applications.

- Gildan Activewear: A Canadian manufacturer of basic and activewear apparel, known for its quality and sustainable practices.

- Standard Textile Co: A leading provider of textiles and apparel for the healthcare, hospitality, and home markets.

- Cintas Corporation: A company that provides specialized services, including uniform rental and apparel for various industries, such as healthcare, hospitality, and corporate.

- Sherwin-Williams Company: While primarily known for its paint and coatings, Sherwin-Williams also produces specialty fabrics for industrial applications.

- Fruit of the Loom, Inc: A well-known manufacturer of underwear, casualwear, and activewear for consumers worldwide.

- Parkdale Mills: A leading manufacturer of spun yarns and specialty fabrics for the apparel and home furnishings industries.

- Levi Strauss & Co: An iconic American company famous for its denim jeans and casual apparel.

- Nike, Inc.: A global sportswear and athletic footwear brand that also produces performance fabrics for its apparel lines.

- Lantic Inc.: A Canadian sugar company that also produces a wide range of sustainable and biodegradable fibers for the textile industry.

- Stanfield’s Ltd.: A Canadian company specializing in manufacturing woolen products, including thermal underwear and workwear.