Structural Crack Detectors

GAO’s structural crack detectors are devices or systems designed to detect cracks or damage in structural components of buildings, bridges, pipelines, and other infrastructure. These detectors are used to monitor and assess the health of structures, identify potential problems, and facilitate timely repairs to prevent further damage or failure.

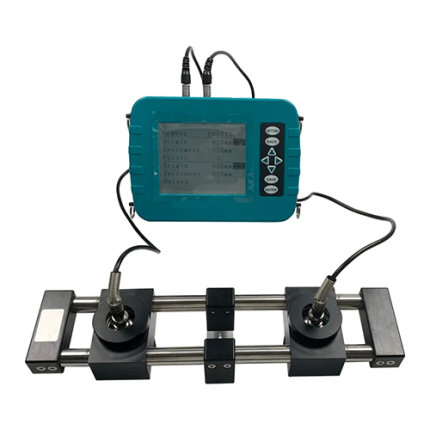

GAO’s structural crack detectors are composed of sensors, data acquisition system, power source, display or output device, mounting hardware, and communication equipment.

The other common names for crack detectors are fracture sensors, fault detectors, flaw identifiers, breakage detectors, defect finders, imperfection sensors, damage detectors, flaw detectors, weakness identifiers, break detectors, deficiency sensors, fault finders, damage identifiers, and fracture detectors.

GAOTek Digital Crack Detector

GAOTek Digital Crack Detector

GAOTek Accurate Concrete Crack Detector

GAOTek Accurate Concrete Crack Detector

GAOTek Automated Flaw Display Detector

GAOTek CDDL Crack Ultrasonic Concrete Cover Thickness Tester

GAOTek Coating Crack Detector

GAOTek Concrete Automatic Digital Crack Detector

GAOTek Concrete Crack Depth and Width Detector

GAOTek Concrete Crack Depth and Width Detector

GAOTek Concrete Crack Depth And Width Detector

GAOTek Concrete Crack Depth And Width Detector

GAOTek Concrete Crack Depth Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector

GAOTek Concrete Crack Detector – Compact Size

GAOTek Concrete Crack Detector Meter

GAO’s structural crack detectors have the following functions:

- Early detection of cracks and damage: One of the primary functions of GAO’s structural crack detectors is to detect cracks and other types of damage in structural components before they lead to failure. Early detection allows for prompt repairs, which can prevent more significant damage and potential safety hazards.

- Monitoring structural health: GAO’s structural crack detectors can continuously monitor the health of structures over time, providing important information about changes in structural conditions and identifying potential problems as they arise.

- Assessing structural integrity: By identifying cracks and other types of damage, our structural crack detectors can help assess the overall integrity of a structure and determine whether it is safe for use.

- Predicting potential failures: Our structural crack detectors can be used to predict potential failures by identifying patterns of damage or changes in structural conditions that may indicate an increased risk of failure.

- Facilitating repairs: Once cracks or damage are detected, GAO’s structural crack detectors can help facilitate repairs by identifying the location and extent of the damage, providing important information for planning and executing repairs.

GAO’s structural crack detectors are rugged, versatile and precision measurement instruments. They comply with applicable industry standards such as ASTM E1417, ASTM E164, ASTM E543, ASNT SNT-TC-1A, ISO 9712, and EN 4179.

Our structural crack detectors help its clients to comply with relevant U.S. government regulations such as:

- Federal Aviation Administration (FAA) - Part 43

- Occupational Safety and Health Administration (OSHA)

- Pipeline and Hazardous Materials Safety Administration (PHMSA) - Part 192

- Nuclear Regulatory Commission (NRC) - Part 50

Our structural crack detectors help its clients to comply with relevant Canadian government regulations such as:

- Transport Canada - Canadian Aviation Regulations (CARs) - Part V

- Canadian Standards Association (CSA) - CSA W178.1

- National Energy Board (NEB) - Onshore Pipeline Regulations

- Canadian Nuclear Safety Commission (CNSC) - Radiation Protection Regulations

- Canadian Welding Bureau (CWB) - CSA W178.2

GAO’s structural crack detectors have the following applications:

- Building inspection: GAO’s structural crack detectors are used to inspect buildings for cracks or other types of damage. This is important for ensuring the safety of occupants and preventing potential structural failures.

- Bridge inspection: Bridges are subject to a variety of stresses and strains, which can lead to cracks and other types of damage. GAO’s structural crack detectors are used to inspect bridges for potential problems and identify areas that require maintenance or repair.

- Pipeline inspection: Pipelines are used to transport oil, gas, and other fluids over long distances. Our structural crack detectors are used to inspect pipelines for cracks and other types of damage that could lead to leaks or failures.

- Wind turbine inspection: Wind turbines are subject to significant stresses and vibrations, which can lead to cracks and other types of damage. Our structural crack detectors are used to inspect wind turbines for potential problems and identify areas that require maintenance or repair.

- Aircraft inspection: GAO’s structural crack detectors are used to inspect aircraft for potential cracks or other types of damage that could compromise the safety of passengers and crew.

- Power plant inspection: Power plants are subject to high temperatures and pressures, which can cause structural components to degrade over time. Our structural crack detectors are used to inspect power plants for potential problems and identify areas that require maintenance or repair.

Below are our resource pages containing useful information on Crack Detectors:

FAQ on Crack Detectors

How to Choose a Crack Detector

Components of a Crack Detector

Operation, Maintenance, Calibration of a Crack Detector

Customers of Crack Detectors in the U.S. and Canada

Applications of Crack Detectors in Finance and Insurance Industry

Applications of Crack Detectors in Agriculture Industry

Applications of Crack Detectors in Accommodation and Food Services Industry

Our structural crack detectors can be shipped overnight within the continental U.S. and Canada, and can be shipped globally.