Ultrasonic & Mass Flow Meters

GAO’s ultrasonic & mass flow meters are two types of instruments used in construction and engineering. Ultrasonic meters use ultrasonic waves to detect and measure the thickness of materials, such as steel plates, concrete walls, and pipes. These devices send high-frequency sound waves through the material and measure the time it takes for the waves to bounce back. By analyzing the time and intensity of the reflected waves, ultrasonic meters can determine the thickness of the material. Mass flow meters, on the other hand, are devices used to measure the flow rate of fluids, such as water or gas, in pipes or channels. They use a variety of methods to measure the flow rate, including thermal mass flow meters, and differential pressure meters. The information gathered by mass flow meters is essential in the design and operation of many types of, such as water treatment plants, chemical processing facilities, and HVAC systems.

GAO’s ultrasonic & mass flow meters are composed of transducer, pulser or receiver, display, data logger, flow sensor, transmitter, control unit, and output unit.

The other common names of ultrasonic and mass flow meters are acoustic flow meters, sonic flow meters, doppler flow meters, transit-time flow meters, time-of-flight flow meters, clamp-on flow meters, non-intrusive flow meters, liquid ultrasonic flow meters, gas ultrasonic flow meters, portable ultrasonic flow meters, in-line ultrasonic flow meters, inline acoustic flow meters, mass flow controllers (MFCs), mass flow sensors, coriolis mass flow meters, thermal mass flow meters, gas mass flow meters, liquid mass flow meters, micro flow meters, insertion mass flow meters, inline mass flow meters, compact mass flow meters and high-pressure mass flow meters.

Clamp-On Ultrasonic Flow Meter with Wireless IoT Communication – GAOTek

Compact and Wall-mounted Housing Stainless Steel Flowmeter – GAOTek

Electromagnetic Flowmeter for Advanced Process and Custody Transfer – GAOTek

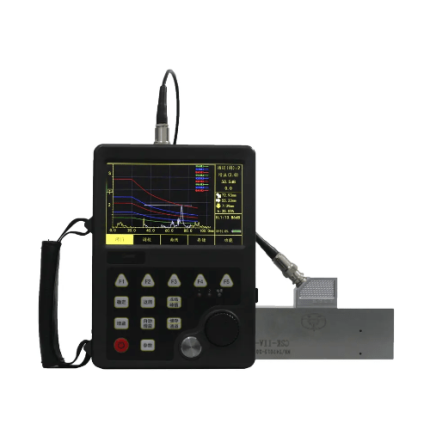

GAOTek Digital Ultrasonic Flaw Detector

GAOTek Digital Ultrasonic Flaw Detector

GAOTek Portable Digital Ultrasonic Flaw Detector

GAOTek Ultrasonic Testing Concrete

GAOTek Bracket Sensor Portable Ultrasonic Flow Meter

GAOTek Calibration Steam Flow Meter

GAOTek Carbon Steel Ultrasonic Flow Meter

GAOTek Cheap Ultrasonic Flow Meter

GAOTek Clamp On Ultrasonic Flow Meter

GAOTek Clamp On Ultrasonic Flow Meter

GAOTek Clamp-On Ultrasonic Liquid Flow Meter

GAOTek Compressed Air Flow Meter

GAOTek Diesel Fuel Oil Mechanical Flow Meter

GAOTek Diesel Micro Flow Meter

GAOTek Diesel Paddle Wheel Water Flow Meter

GAOTek Digital Electromagnetic Ultrasonic Flow Meter

GAOTek Digital Electromagnetic Ultrasonic Liquid Flow Meter

GAOTek Digital Portable Ultrasonic Flow Meter

GAOTek Digital Portable Ultrasonic Flow Meter

GAO Tek’s structural ultrasonic & mass flow meters have the following functions:

- Measure thickness: The primary function of our structural ultrasonic meters is to measure the thickness of materials, such as steel plates, concrete walls, and pipes. This information is used to assess the structural integrity of the material and to detect any signs of corrosion or other defects.

- Identify flaws: GAO’s structural ultrasonic meters can also be used to identify flaws in materials, such as cracks, voids, or delaminations. This information can be used to determine the need for repairs or to assess the safety of the structure.

- Provide data logging: Our ultrasonic meters are equipped with data logging capabilities, which allow operators to record thickness readings over time. This information can be used to track changes in material thickness and to identify trends that may indicate corrosion or other problems.

- Measure flow rate: The primary function of our mass flow meters is to measure the flow rate of fluids, such as liquids and gases, in pipes or channels. This information is used to monitor and control the flow of fluids in a variety of applications, such as chemical processing, water treatment, and HVAC systems.

- Ensure accuracy: GAO’s mass flow meters are designed to provide highly accurate flow rate measurements, which are essential in many industrial processes. They can be calibrated to ensure that the readings are consistent and reliable over time.

- Control flow: Our mass flow meters can also be used to control the flow of fluids in a system. They can be integrated with other equipment, such as pumps or valves, to ensure that the flow rate remains within a specified range.

GAO Tek’s structural ultrasonic & mass flow meters are rugged, versatile and precision measurement instruments. They comply with applicable industry standards such as ASTM E119, ASTM E2126, ACI 318, AISC 360, and ASCE 7.

Our structural ultrasonic & mass flow meters help our customers comply with relevant U.S. government regulations such as:

- Occupational Safety and Health Administration (OSHA) regulations

- National Fire Protection Association (NFPA) regulations

- Federal Aviation Administration (FAA) regulations

- Department of Transportation (DOT) regulations

Our structural ultrasonic & mass flow meters help our clients in complying with relevant Canadian government regulations such as:

- Canadian Standards Association (CSA) regulations

- Occupational Health and Safety (OHS) regulations

- Transportation Association of Canada (TAC) regulations

- Canadian Aviation Regulations (CARs)

Our structural ultrasonic & mass flow meters have the following applications:

- Inspection of structural materials: GAO’s structural ultrasonic meters are used in the inspection of materials used in construction, such as steel, concrete, and pipes. They are used to detect cracks, voids, and other defects that may affect the structural integrity of the material.

- Corrosion detection: GAO’s ultrasonic meters are also used to detect corrosion in metals, such as pipes and tanks. By measuring the thickness of the metal, operators can identify areas where corrosion has occurred and take corrective action.

- Aerospace and aviation: Our ultrasonic meters are used in the aerospace and aviation industries to inspect aircraft components, such as wings, fuselages, and landing gear, for signs of damage or wear.

- Chemical processing: GAO’s mass flow meters are used in chemical processing applications to measure the flow of liquids and gases through pipelines. This information is used to ensure that the correct amount of material is being delivered and to maintain consistent process conditions.

- HVAC systems: Our mass flow meters are used in HVAC (heating, ventilation, and air conditioning) systems to measure the flow of air and water through ducts and pipes. This information is used to optimize the efficiency of the system and to maintain consistent conditions.

- Food and beverage production: Our mass flow meters are used in food and beverage production to measure the flow of liquids, such as milk, juice, and beer, through pipelines. This information is used to ensure that the correct amount of material is being delivered and to maintain consistent product quality.

Below are our resource pages containing useful information on Ultrasonic & Mass Flow Meters:

FAQ on Ultrasonic & Mass Flow Meters

How to Choose an Ultrasonic Mass Flow Meter

Components of an Ultrasonic Mass Flow Meter

Operation, Maintenance & Calibration of a Ultrasonic & Mass Flow Meters

Customers of Ultrasonic and Mass Flow Meters in the U.S. and Canada

Applications of Ultrasonic & Mass Flow Meters in the Automotive Industry

Applications of Ultrasonic & Mass Flow Meters in the Semiconductor Manufacturing Industry

Applications of Ultrasonic & Mass Flow Meters in the Water and Wastewater Treatment Industry

Applications of Ultrasonic & Mass Flow Meters in the Chemical Processing Industry

Applications of Ultrasonic & Mass Flow Meters in the Agriculture and Irrigation Industry

Applications of Ultrasonic & Mass Flow Meters in the Mining and Minerals Processing Industry

Applications of Ultrasonic & Mass Flow Meters in the Oil and Gas Industry

Applications of Ultrasonic & Mass Flow Meters in the Food and Beverage Industry

Applications of Ultrasonic & Mass Flow Meters in Environmental Monitoring Industry

Applications of Ultrasonic & Mass Flow Meters in the HVAC Industry

Our structural ultrasonic and mass flow meters can be shipped overnight within the continental U.S. and Canada, and can be shipped globally.