Description

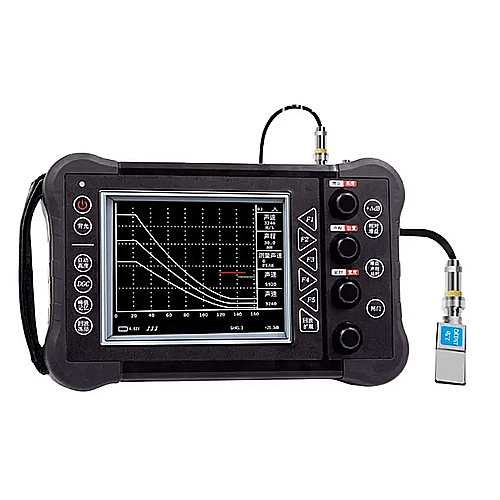

Overview

GAOTek ultrasonic flaw detector are capable of Instrument and probe performance of the type of digital ultrasonic flaw detector is automatic measurement, instrument calibration is automatic, thickness and material sound velocity can be measured, suitable for manual detection of irregular parts such as stamping parts, forging, and die.

Features

- Automatic instrument and probe performance measurements

- Automatic instrument calibration for thickness and material sound velocity

- Customizes flaw detection processes based on the work piece

- Provides real time display of flaw echoes horizontal, vertical and distance

Technical Specifications

| Material Velocity | 1000 m/s to 9999 m/s |

| Gain Margin | 0 dB to 110 dB |

| Vertical Linear Error | ≤3% |

| Horizontal Linear Error | ≤3% |

| Dynamic Range | >32 dB |

| Sensitivity Leavings | >58 dB |

| Resolution | >26 dB |

| Power Supply | Lithium batteries work for 4 hrs to 8 hrs |

| Frequency Bandwidth | 0.4 MHz to 10.0 MHz |

| Inhibition Of Range | 0% to 50% |

| Increment | 0 dB to 20 dB |

| Compensation | -20 dB to 20 dB |

| Noise Level | <10% |

| Working Voltage | DC 9 V to 15 V |

| Operating Temperature | 14 ℉ to 122 ℉ (-10 ℃ to 50 ℃) |

| Storage Temperature | -4 ℉ to 158 ℉ (-20 ℃ to +70 ℃) |

| Test Range | 0 in to 236.22 in (0 mm to 6000 mm) |