Description

Overview

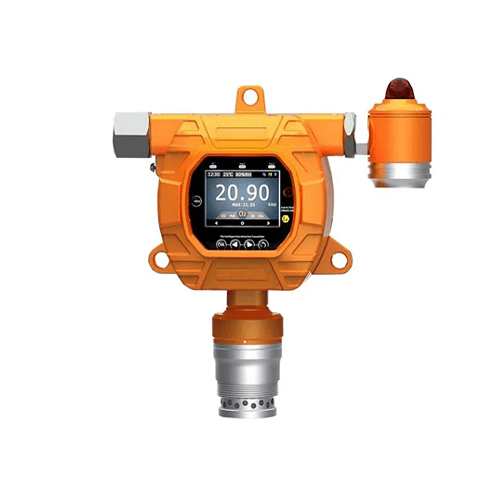

GAOTek gas detector leak analyzer is used for on-site gas concentration detection and alarm for excessive gas concentration. It can detect the concentration of various toxic and harmful flammable gases and display the real-time concentration value and standard signal output on the spot. Use imported brand gas sensors. The main detection principles are electrochemistry, infrared, catalytic combustion, thermal conductivity, and PID photo ions. It has the advantages of stable signal, high sensitivity, and precision, and the flameproof wiring method is suitable for various dangerous places.

Features

- Explosion-proof

- anti-lightning, anti-static

- reverse connectionanti-EMI EMC electromagnetic interference,

- anti-pulse surge current impact.

- Comply with the latest national standards

- Three-wire system or four-wire system

- It also has a standard bus system RS 485 output (RTU format)

- Optional with extra charge wired transmission, LAN, Internet, wireless transmission

- The wireless transmission method can be 433, GPRS, WIFI, and other methods.

- The remote-control distance is 49.21 ft (15 m)

- Each unit can be switched to each other

- It can communicate with the computer

Technical Specifications

| Detection gas | Arsenide AsH3 |

| Scope of detection | 0 ppm to 10 ppm, 50 ppm, 1.000 ppm |

| Resolution | 0.01 ppm, 0.001 ppm |

| Detection principle | Electrochemical principles |

| Sensor life | 2 years |

| Detection accuracy | ≤ ± 3% F.S |

| Linearity | ≤ ± 2% |

| Repeatability | ≤ ± 2% |

| uncertainty | ≤ ± 2% |

| Recovery Time | ≤ 30 S |

| Response time | T 90 ≤20 S |

| Signal output | Bus system RS 485 (RTU), three (four) wire system 4 mA to 20mA, Optional 0 mA to 20 mA, 1 V to 5 V, 0 V to 5 V, 0 V to 10 V, wireless transmission, network transmission, SMS alarm. |

| Display method | 1.7 in (43.2 mm) high definition colour screen display on site |

| Operating Voltage | 12 V to 36 V DC, the standard power supply of a single device is 24 V, 1 A or more than 1 A DC regulated switching power supply |

| Power reference | 24 V, 2.1 A switching power supply can drive 40 toxic gas detectors or 15 combustible and infrared gas detectors |

| Way of working | Fixed installation, online detection, diffusion measurement; pipeline, flow, and pump-suction measurement are available. |

| Installation method | Pipeline type and wall-mounted type. The working pressure of the pipeline type is ± 30% of the atmospheric pressure, and the pressure needs to be reduced if it exceeds the range. |

| Alarm method | The default is 1 channel, optional 2 passive contacts (dry node) output, three-level alarm, and the alarm point can be set. On-site sound and light alarm (optional). |

| Connecting cables | 4 mA to 20 mA three-core shielded cable, RS485 select four-core, single wire diameter 0.06 in (1.5 mm) when the distance exceeds 3,280.84 ft (1000 m); the shielding layer is connected to the earth. |

| Protection level | IP 65 |

| Explosion-proof | Flameproof, ExdIICT6Gb |

| Packing list | Manual, warranty card, packing box |

| Optional accessories | Integrated alarm lamp, power adapter, split alarm lamp, drying cylinder, flow-through connector, threaded welding seat, AC pump, DC brushless pump, vacuum pump, rain cover, water vapor filter, U-shaped buckle, 304 L / 316 L / 316 L stainless steel gas chamber, 304 L / 316 L / 316 L stainless steel housing |

| Optional function | Wireless transmission, Hart protocol output, split detection |

| Working environment | Temperature -40.00 °F to 158.00 °F (-40 °C to 70 °C), humidity ≤ 10% RH to 95% RH (normal) |

| Dimensions | 9.37 in × 5.98 in × 3.54 in (238 mm × 152 mm × 90 mm) without alarm, 9.37 in × 8.27 in × 3.54 in (238 mm × 210 mm × 90 mm) with alarm |

| Weight | without alarm 3.04 lb. (1.38 Kg) with alarm 3.52 lb. (1.6 kg) |