Description

Overview

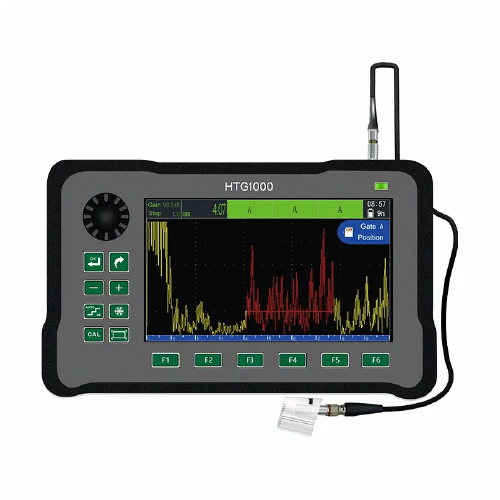

GAOTek Ultrasonic Stainless Steel High Precision Flaw Detector has almost no resistance to ultrasonic waves. while materials that have not undergone hardening treatment will scatter a large number of ultrasonic waves. The detection system records the backscatter signal and processes it with our electronic measuring element, the final hardened depth of the material can be obtained.

Features

- Measurement equipment can be integrated into production process

- Quickly obtain measurement results

- Large number of parts can be evaluated very quickly

- By using workpiece of different sizes can be measured

- The device can move freely

- Parameters can be easily adjusted

Technical Specifications

| Object to be Measured | Depth of the induction hardened layer |

| Measurement Range | 0.02 in to 0.59 in (0.7 mm to 15 mm) |

| Measurement Resolution | 3.93 in (0.1 m) |

| Measurement Repeatability | ±0.00 in (±0.1 mm) |

| Sensibility | 80 dB or more (5 MHz narrow band) |

| Adjustable Gain | Max 120 dB Min 0.1 dB pitch |

| Center Frequency of Receiving Amplification | 1 Mhz to 20 Mhz |

| Vertical Linearity | Within ±2.8% |

| Horizontal Linearity | Within ±0.6% |

| AC Charger | AC 65 W fast charging input 100 V to 240 V ±10 % 50 Hz or 60 Hz ±3 Hz |

| Battery | Lithium-ion battery |

| Charging Time | 1.5 h |

| Operating Time | About 12 h (Varies depending on user usage conditions) |

| Ambient Temperature | 32 ℉ to 122 ℉ (0 ℃ to 50 ℃) (during operation) -4 ℉ to 140 ℉ (-20 ℃ to 60 ℃) (during storage) |

| Display and Screen Size | 5.0-in LCD HD screen |

| External Dimensions (mm) | 7.20 in × 4.44 in × 1.77 in (183 mm × 113 mm × 45 mm) |

| Weight (g) | 1.72 lb (780 gm) |