Description

Features

- Digital interfaces enable connection to higher-level systems

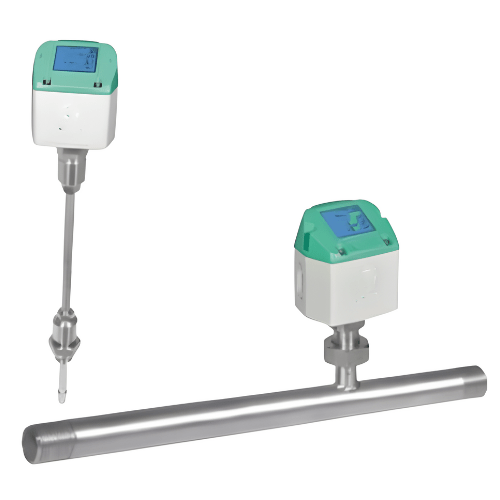

- It is an easy and awardable installation

- Units freely selectable via keys at the display

- Compressed air counter up to 1.999.999.999 m³

- High measuring accuracy in the lower measuring range

- Negligibly small loss of pressure

- Calorimetric measuring principle, no additional pressure/temperature measurement

- Comprehensive diagnosis functions can be read out

Technical Specifications

| Parameters | m³/h, l/min (1000 mbar at compressed air, or Nm³/h, Nl/min (1013, mbar) for gases |

| Units Adjustable Via Keys At Display | m³/h, m³/min, l/min, l/s, ft/ min, cfm, m/s, kg/h, kg/min, g/s, lb/min, lb/h |

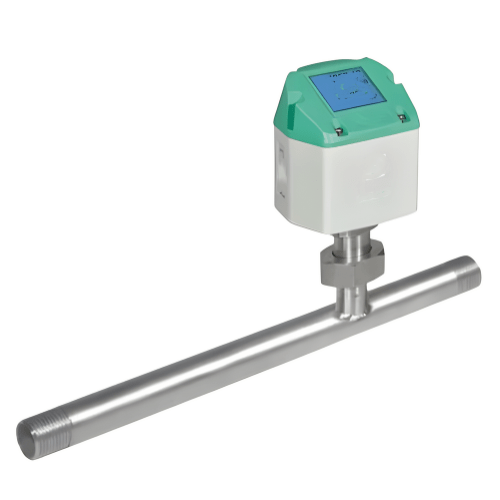

| Sensor | Thermal Mass Flow Sensor |

| Measuring Medium | Air, Gases |

| Gas Types Are Adjustable Over CS Service | Air, Nitrogen, Argon, Helium, CO2, Oxygen, Vacuum |

| Accuracy (M.V.: Of Meas. Value) (F.S.: Of Full Scale) | ± 1.5 % of m.v. ± 0.3 % of f.s. on request ± 1.0 % of m.v. ± 0.3 % of f.s. |

| Operating Pressure | -1 to 16 bars optional to PN 40 |

| Digital Output | RS 485 interface (Modbus-RTU), Optional: Ethernet-Interface PoE), M-Bus |

| Analog Output | 4 mA to 20 mA for m³/h e. g. l/min; |

| Pulse Output | 1 Pulse per m³ or per liter galvanically isolated. Pulse value can be set on the display. Alternatively, the pulse output can be used as an alarm relay |

| Supply | 18 VDC to 36 VDC, 5 W |

| Burden | < 500,000 |

| Housing | Polycarbonate (IP 65) |

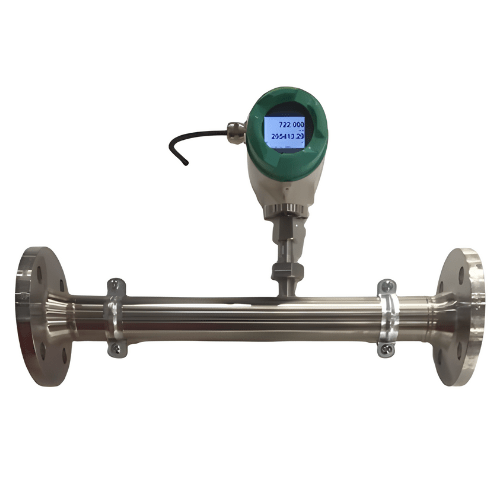

| Measuring Section | Stainless Steel, 1.4301 or 1.4571 |

| Process Connection | Flange (to DIN EN 1092-1e. g. ANSI 150 Ibs or ANSI 300 Ibs) |

| Ø Casing | 2.56 in (65 mm) |

| Operating Temperature | -22 °F to 176 °F (-30 °C to 80 °C) |