Description

Overview

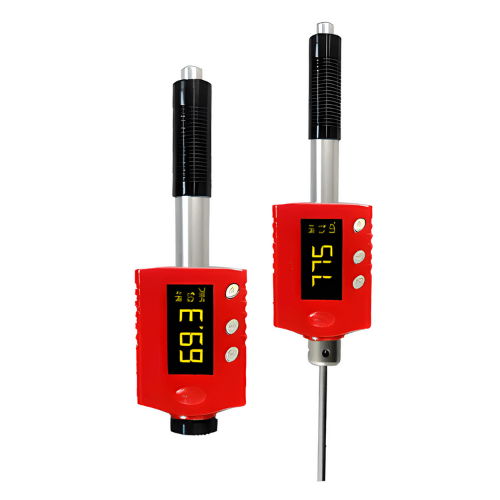

GAOTek Digital Portable Metal Rockwell Hardness Tester is an advanced state-of-the-art palm sized metal hardness tester with many new features. Which is light weight, easy operation, integrated design, high contrast display, low operating temperature, auto compensating for impact direction, etc. It can be widely used for measuring hardness of almost all ferrous and non-ferrous metal materials for scale of Leeb hardness, Rockwell C & B, Brinell, Vickers, Shore and Strength.

Features

- Palm sized and easy operation

- High contrast OLED display

- Auto switch on & off

- Recognize impact direction automatically

- Duplex readings on display

- Large digits and more readings alternatively

- Four display orientations

- Vast memory capacity

- USB/RS 232 interface

- Micro-printer can be used on site

- Recalibration allowed by user

- Liner compensates for angle measurement

Technical Specifications

| Principle | Leeb hardness measurement |

| Accuracy | – 0.3% to 0.3% HL 800 or -2 HL to 2HL |

| Display | digital with high contrast LED |

| Display Mode | Normal or flip |

| Hardness Scale | HL or HRC or HRB or HB or HV or HS or db |

| Measuring Range | HL (170 to 960) or HRC (17 to 70) or HRB (13 to 109) or HB (20 to 655) or HV (80 to 940) or HS (32 to 99.5) or HRA (30 to 88) or db (rm) (255 to 2639) N/mm² |

| Impact Device | D (Internal) D or DL 2 in 1 (Internal, optional) |

| Materials | 11 common metal materials |

| Memory | 3,000 data |

| Statistics Function | Average or Max or Min or value |

| Recalibration | Allowed by user |

| Interface | USB for data transferring to PC and charging battery |

| Indicator | Low battery |

| Power On/Off | Auto |

| Power Supply | 3.7 V Li ion rechargeable battery |

| Working Environment | –40 °F to 158 °F (-40 °C to 70 °C) |

| Standard | ASTM A 956, DIN 50156, GBT 17394 to 1998 |

| Dimension | 5.8 in x 1.7 in x 0.8 in (148 mm x 44 mm x 22 mm) |

| Net Weight | 0.2425 lb (110 g) |