Description

Overview

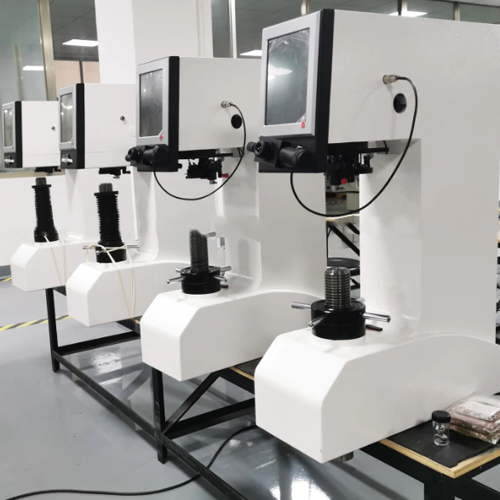

GAOTek Hardness Testers features the hardness tester that operates based on the Brinell hardness testing method, which involves applying a known load to a spherical indenter made of hardened steel or tungsten carbide. The indentation is pressed into the material’s surface for a specific duration, creating an indentation. The tester is equipped with an automatic testing system, which allows for precise and repeatable testing with minimal user intervention. This automation ensures consistent and accurate hardness readings.

Features

- With 12 kinds of measurement scale

- Closed-loop control, with high accuracy load cell, no need to install weights, easy installation, and calibration.

- Measuring indentation automatically, no need to focus

Hardness value display on screen, and with hardness conversion function. - Test force with automatic calibration function, load automatic corrected, much more accuracy.

- Hardness value automatic corrected according to different hardness block

Technical Specifications

| Load accuracy | 0.1%. Better than normal Brinell hardness tester 1% (above 1000 Kgf) |

| microscope magnification | 20X (option: 10X, 15X, 30X) |

| Min measuring unit | 0.625 µm (option:0.3125 µm) |

| Dwell time | 5 s to 60 s |

| Hardness range | 8-650 HBW |

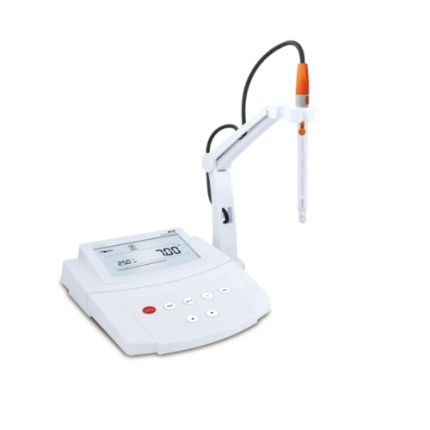

| Data output | LCD display, USB interface saved in USB flash disk (save in Excel format) |

| Executive Standard | ISO 6506, ASTM E10-12, JIS Z2243, GB/T 231.2 |

| Power supply | AC220 + 5%,50 to 60 Hz |

| Overall Dimension | 21.65 in x 8.26 in x 29.52 in (550 mm x 210 mm x 750 mm) |

| Net weight | About 12.12 lb. (5.5 kg) |