Description

Features

- Explosion-proof, anti-lightning, anti-static, anti-EMI features

- Complies with national standards and certifications

- Offers 4 mA to 20 mA signal output, voltage output

- Includes relay switch values for safety measures

- Features RS 485 output with optional alarm integration

- Offers wired, LAN, Internet, wireless transmission options

- Wireless options include 433, GPRS, WIFI methods

- Standard infrared remote control for safe operation

- Units switchable, tracks zero point to prevent drift

- Multi-level calibration for accurate readings

- Real-time concentration monitoring via computer

- Data storage, analysis, printing capabilities on computer

- Practical remote-control distance of 15 meters

- Comprehensive safety measures for hazardous environments

- Integrated alarm system enhances safety protocol

Technical Specifications

| Detection Gas | Hydrogen cyanide |

| Scope Of Detection | 0 ppm to 10 ppm, 30 ppm, 100 ppm, 200 ppm, 500 ppm, 1000 ppm, 5000 ppm |

| Resolution | 0.01 ppm, 0.1 ppm, 1 ppm |

| Detection Principle | Electrochemical principles |

| Sensor Life | 2 years |

| Detection Accuracy | ≤ ± 3 % F.S |

| Linearity | ≤ ± 2 % |

| Repeatability | ≤ ± 2 % |

| Uncertainty | ≤ ± 2 % |

| Recovery Time | ≤ 30 S |

| Response Time | T 90 ≤ 20 S |

| Signal Output | Bus system RS485 (RTU), three (four) wire system 4 mA to 20 mA, Optional: 0 mA to 20 mA, 1 V to 5 V, 0 V to 5 V, 0 V to 10 V, wireless transmission, network transmission, SMS alarm. |

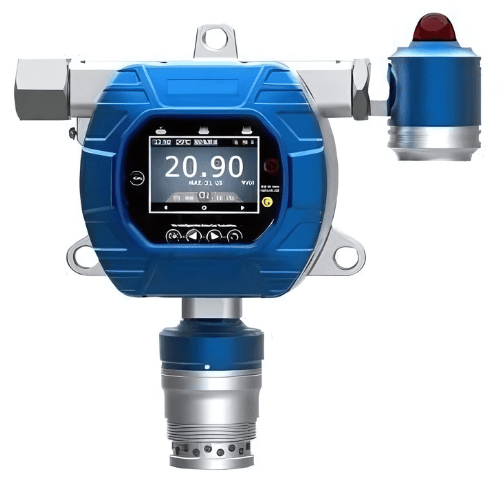

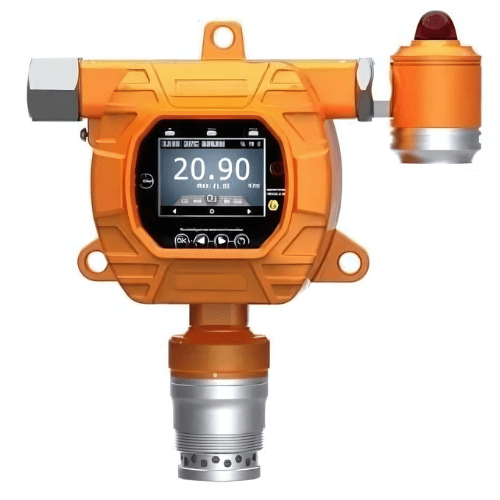

| Display Method | 1.7 inch high-definition color screen display on site |

| Operating Voltage | 12 V DC to 36 V DC, the standard power supply of a single device is 24 V, 1 A or more than 1 A DC regulated switching power supply |

| Power Reference | 24 V, 2.1 A switching power supply can drive 40 toxic gas detectors, or 15 combustible and infrared gas detectors |

| Way of Working | Fixed installation, online detection, diffusion measurement; pipeline, flow, and pump-suction measurement are available. |

| Installation Method | Pipeline type and wall-mounted type. The working pressure of the pipeline type is ± 30 % of the atmospheric pressure, and the pressure needs to be reduced if it exceeds the range. |

| Alarm method | The default is 1 channel, optional 2 passive contact (dry node) output, three-level alarm, and the alarm point can be set. On-site sound and light alarm (optional). |

| Connecting Cables | 4 mA to 20 mA three-core shielded cable, RS 485 select four-core, single wire diameter ≥ 1.5 mm when the distance exceeds 1000 m; the shielding layer is connected to the earth. |

| Protection Level | IP 65 |

| Explosion-Proof | Flameproof, ExdIICT6Gb |

| Packing List | Manual, warranty card, packing box |

| Optional Accessories | Integrated alarm lamp, power adapter, split alarm lamp, drying cylinder, flow-through connector, threaded welding seat, AC pump, DC brushless pump, vacuum pump, rain cover, water vapor filter, U-shaped buckle, 304 or 316 or 316 L stainless steel gas chamber, 304 or 316 or 316 L stainless steel housing |

| Optional Function | Wireless transmission, Hart protocol output, split detection |

| Humidity | ≤ 10 % RH to 95 % RH |

| Temperature | −40 °F to 158 °F (-40 ºC to +70 ºC) |

| Dimensions | 9.37 in x 5.98 in x 3.54 in (238 mm x 152 mm x 90 mm) without alarm, 9.37 in x 8.26 in x 3.54 in(238 mm x 210 mm x 90 mm) with alarm |

| Weight | without alarm 3.04 lb. (1.38 Kg) with alarm 3.52 lb. (1.6 kg) |