Description

Overview

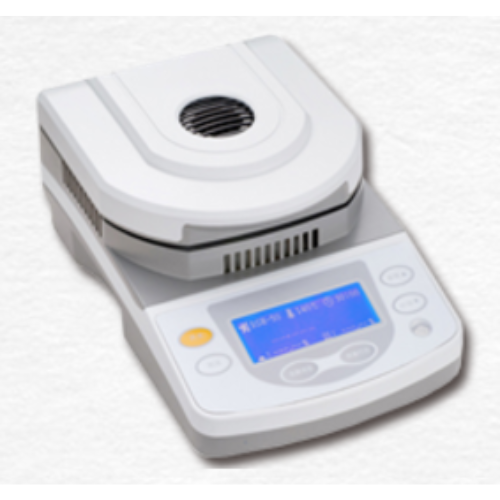

GAOTek Moisture Analyzer with High Precision (Automatic Peeling) is designed with high resolution lattice LCD backlight and can be used to test the moisture of products with various weighing range. It provides the high precision heat insulation type sensor. The testing time is shorter and can measure immediately and continuously with automatic peeling function. It supports RS232 Interface and can be directly connected to computer and printers. GAOTek Moisture analyzer can be used to test the free content of chemical raw materials, grain, mineral, biological product, food, pharmaceutical raw materials, paper, textile raw materials etc.

Key Features

- High resolution back window matrix liquid crystal display.

- Easy to operate in dark places.

- Halide torch used for heating and drying.

- Touch tone chain plate makes the operation easier.

- High precision heat insulation type sensor.

- Continuous and quick measurement.

- Accurate measurement through zero drift correction

- Water resistance and dustproof.

Technical Specifications

| Weighing Range | 0.35 oz.(10 g) | 1.76 oz.(50 g) | 1.76 oz. (50 g) | 1.76 oz. (50 g) | 3.53 oz. (100 g) |

| Readability | 0.15 gr

(10 mg) |

0.08 gr

(5 mg) |

0.02 gr

(1 mg) |

0.15 gr

(10 mg) |

0.02 gr

(1 mg) |

| Repeatability

(3 g Samples) |

0.50 % | 0.30 % | 0.20 % | 0.50 % | 0.30 % |

| Minimum Sample Amount | 0.02 oz. (0.5 g) | ||||

| Advised Sample Amount | 0.11 oz. to 0.35 oz. (3 g to 10 g) | ||||

| Heat up Time | 1 minutes to 99 minutes, 1 minutes interval | ||||

| Interface | RS232 | ||||

| Temperature Program | Standard | ||||

| Heating Temperature Range | 122 °F to 356 °F (50 °C to 180 °C) | ||||

| Display Information | Moisture %, Solid %, Weight, Time Data etc. | ||||

| Pan Size | 3.94 in (100 mm) | ||||

| Power Input | 100 V to 120 V (AC), 50 Hz/60 Hz, 3A

200 V to 240 V (AC), 50 Hz/60 Hz, 3A |

||||

| Voltage Fluctuations | -15 % to + 10 % | ||||

| Power Load | 250 W | ||||

| Warm up Time | 30 minutes | ||||

| Power Line Fuse | 0.2 in x 0.79 in (5 mm x 20 mm), 8A 250V (1 piece) | ||||

| Heating Source | Halide Torch | ||||

| Dimension | 10.43 in × 6.3 in × 5.91 in (265 mm × 160 mm × 150 mm) | ||||

| Weight | 11.02 lbs. (5 kg) | ||||

| Humidity | 15 % to 80 % (non-condensing) | ||||

| Storage Temperature | 50 °F to 104 °F (10 °C to 40 °C) | ||||

Additional Information

Ordering Information:

| Models | GT00XX00ZU-A | GT00XX00ZU-B | GT00XX00ZU-C |

| Weighing Range | 0.35 oz.

(10 g) |

1.76 oz.

(50 g) |

3.53 oz.

(100 g) |

| Repeatability

(3 g Samples) |

0.50 % | 0.50 % | 0.30 % |

Accessories:

- Moisture Analyzer

- Draft shield

- Sample pans

- Pan support

- Scale pliers

- Weight pliers

- Weight 0.35 oz./1.76 oz./3.53 oz. (10 g/50 g/100 g)

- User manual

- Power cable

Selecting the Location:

- Operate the Analyzer on a firm, level surface.

- Select a location that is safe and with adequate ventilation. Fire, corrosive or toxic fumes and other hazards associated with the test samples will require specially prepared locations.

- Ensure that the location has easy access to the local AC power supply.

- Avoid locations with rapid temperature changes, excessive humidity, air currents, vibrations, electromagnetic fields heat or direct sunlight.

Installing Components:

- Install and position the Draft Shield

- Install the Pan Support, turn until it engages into position

- Place a sample pan over the pan support

Connecting Power

Verify the input voltage printed on the voltage identification label information and the plug type matches the locations AC power supply.

Connect the given power cable to the power input receptacle at the rear of the Analyzer and into a properly grounded power outlet.

After connecting the Analyzer to the AC supply (standby mode), allow the Analyzer to warm up for at least 30 minutes for best results.

Controls:

| Button | Name | Quick Functions | Button | Name | Quick Functions |

|

On/Off | On (short press)/Off (long press) |  |

Set | Increase value (short or long press) |

|

Tare/Back | Tare

(short press) Back (short press) |

|

Set | Decrease value (short or long press) |

|

Temp | Temperature Setting (short press) |  |

Print/Cal | Print (short press)

Calibrate (long press)

|

|

Time | Time Setting (short press) |  |

Test | Start to test (short press)

|

Operating Modes

Standby Mode:

When the Analyzer is connected to AC power and the display is off, the unit is in Standby mode.

- Start (Short press): Turn on the display and enter the Weigh mode.

- Print (Long press): Displays the RS232 settings. Further, (Short press) Re-enters Standby mode (off).

Weigh Mode:

The display shows the weight of items placed on the pan support.

- Tare (Short press): Set the display weight value to zero

- Start (Long press): Enters Standby mode (Off)

The following operations can be initiated:

- Temp (Short press): Enter into Edit mode for the temperature setting and the value blinks

- Time (Short press): Enter into Edit mode for the time setting and the value blinks

- Start (Short press): Activates Run mode, initiates test with a sample greater than 0.5 g

- Cal (Long press): Initiates weight or temperature Calibration.

Temperature / Time Edit Mode (Preparing a Test)

Temperature editing: (50 °C to 160°C in 5° steps)

- Temp (Short press): Enter into Edit mode for the temperature setting and the value will blinks.

- Set (Short or long press): Increases the value of the temperature setting.

- Set (Short or long press) Decreases the value of the temperature setting.

- Tare (Short press): Accepts the blinking value and returns to weigh mode.

- Start (Short press): Exits Edit mode without saving changes.

Note: After 5 seconds of idleness the blink setting is automatically saved and returns to weigh mode.

Run Mode (Performing a Test)

A moisture determination test is initiated. The results in progress are displayed.

- Start (Short press): Activates Run mode, initiates test with a sample greater than 0.5 g

- % g: Changes the unit of the displayed result: weight (grams) > % Moisture > % Solids.

- Stop (Short press): Manually stops the test in progress.

- Print: Send the current displayed value to the RS232.

Result Mode:

At the end of the test (Run Mode), the display blinks the test result.

- % g: Changes the unit of the displayed result: weight (grams) > % Moisture > % Solids.

- Tare: Exits to weigh mode.

- Print: Sends the current displayed value to the RS232.

How to Prepare a Test

Moisture determinations can be made in simple steps. The three steps are:

(1) Setting the drying temperature.

(2) Setting the drying time.

(3) Preparing the sample to be tested.

- Place the Pan Handler with empty test pan on the Pan Support.

- Press Tare and zero out the pan weight.

- Remove the test pan and place the test sample on to the test pan. The sample must be greater than 0.5 g.

- Spread the sample evenly across the test pan.

- Place the test pan with the sample on the Pan Support. The weight value of the sample will be displayed.

How to Perform a Test:

- Close the Heater Cover.

- Press Start to begin the test (press Start again to stop the test in progress).

- When the test is over, the display will blink showing the final result.

- To change the displayed units, press %, g.

- To print the current displayed value, press Print.

- Press Tare to exit to weigh mode.

Performing a Trial Test

Prior to actual testing, a test run can be performed with these suggested settings:

- Temperature = 120

- Time = AUTO

- Sample = 3 g of water. Place a glass fiber pad (included with the Analyzer) on the test pan, place on the Pan Support. Press Tare to zero the pan weight. Add 3 g of water to the fiber pad.

- Press Start to initiate the test. A perfect result on the trial test would be: 0g, 100% moisture or 0% solids.

TEST OPTIMIZATION

Moisture is determined from the weight loss of a sample dried by heating. The speed and quality of the measurement process will rely on the following parameters. Experimentation will also help ascertain the optimal setup of these parameters:

- Drying temperature

- Drying time

- Sample weight

- Sample preparation

- Type of sample

Sample Weight:

| Sample Weight | Repeatability |

| 0.5 g | ± 1.0 % |

| 1 g | ± 0.6 % |

| 2 g | ± 0.3 % |

| 5 g | ± 0.12 % |

| 10 g | ± 0.06 % |

Types of Samples:

- Liquid substances

- Skin-forming and temperature sensitive substances

- Sugar-containing substances

- Volatile substances

- Poisonous and toxic substances

- Corrosive substances

Communication:

RS232 Pin Connections:

Female DB9 connector:

- Pin 2 Analyzer transmit line (TxD)

- Pin 3: Analyzer receive line (RxD)

- Pin 5: Ground signal (GND)

| RS232 Data Settings | |

| Baud Rate | 9600 mbps |

| Data Bits | 7 bits |

| Parity | N |

| Stop Bits | 2 bits |

Trouble shooting:

| Symptom/ Display | Possible Cause | Remedy |

| Cannot turn On | No power to analyzer | Verify connections and voltage |

| Weight value blinking | Sample weight less than 0.5 g | Increase sample size |

| “Tare” shown | Pan weight needs set to zero | Press Tare |

| “Close Cover” shown | Cover needs to be closed before starting test | Close cover |

| Poor accuracy | Improper calibration | Perform calibration |

| Cannot calibrate | Unstable environment | Move the Analyzer to suitable location |

| Err 7.0 | Incorrect calibration masses

Time out |

Use correct calibration masses |

| Err 8.1 | Pan Support has load during power on | Remove weight from pan support |

| Err 8.2 | Pan Support was removed prior to power on | Install Pan Support |

| Err 8.3 | Weight on Pan Support exceeds capacity | Remove weight from the Pan Support |

| Err 8.4 | Pan Support was removed during weighing | Re-install Pan Support |

| Err 9.5 | Factory calibration data corrupted | Contact the authorized dealer |

| Err 53 | EEPROM Checksum error | Contact the authorized dealer |