Description

Overview

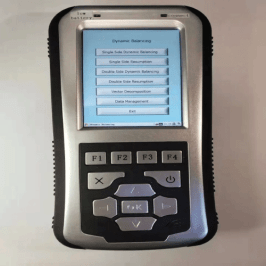

GAOTek portable dual channel vibration analyzer balancer dynamic balance equipment can achieve double sided dynamic balancing correction fast and precisely. The system will automatically calculate the mass size and angle of adding (subtracting) the counterweight. Through the optional vibration analyzing software, we can print all kinds of data information reports. In many cases, a single dynamic balance correction can remove more than 90% of the unbalance of the rotor (shafting) system structure: portable designed, be made up of high speed micro computer and special board.

Features

- The portable dynamic balancing instrument finds extensive application in industrial and mining enterprises

- Offering multiple functions including vibration measurement, vibration analysis, and single and double surface dynamic balancing

- The equipment delivers highly effective balancing results, with straightforward operation, portability, cost effectiveness, and practicality making it an essential tool

- It is suitable for performing dynamic balance correction on various types of rotating machinery

Technical Specifications

| Number of channels | Single / dual channels, and one speed channel is configured |

| Independent signal | Absolute independent signal processing of each channel ensures the independence of each channel signal and eliminates interference between channels |

| Uniformity | Hardware Multi channel simultaneous sampling and holding ensures the absolute same phase of Multi channel vibration signals |

| Gain amplification | The hardware program to controlled gain amplifier can automatically adjust the magnification of 1, 2, 4, 8, 16, 32, 64, 128 and 256, which effectively improves the signal to noise ratio of the signal |

| Multiple filtering | Hardware multiple signal filtering to obtain the target signal flexibly to the greatest extent. Low pass filtering: 600 Hz to 15K Hz section adjustable High pass filtering: 0.1 Hz, 10 Hz, 400 Hz, 1k Hz Anti-aliasing filtering: hardware automatic adjustment |

| Hardware integration processing | Hardware integration processing (without integration, primary integration and secondary integration). If an acceleration sensor is used, three signals of acceleration, velocity and displacement can be obtained |

| High precision AD converter | 14-bit A/D, effectively improve the system accuracy. |

| Rich trigger sources | Internal vibration signal trigger and external speed signal trigger ensure various complex applications |

| System frequency analysis range | 0.1 Hz to 100 KHz |

| Number of spectral lines FFT | 100, 200, 400, 800, 1600, 3200, 6400, 12800 |

| Applicable range of speed | Standard type: 300 rpm to 60000 rpm |

| Operating system | Embedded WINXP |

| Storage capacity | 4G |

| LCD | 3.5 in (88.9 mm) true colour LCD, 640 pixels × 480 pixels |

| Touch screen | Full screen touch operation |

| Vibration accuracy | Vibration parameter accuracy 5 % |

| Speed accuracy | Speed accuracy 1 % |

| working temperature | -4 °F to 122 °F (-20 ℃ to 50 ℃) |

| Ambient humidity | 95 % RH non-condensing |

| Residual unbalance | Mass: 1 mg vibration value: velocity: 0.01 m/s displacement: 0.01 um |

| Power Supply | AC / DC power supply, DC adopts high-capacity rechargeable battery |