Description

Overview

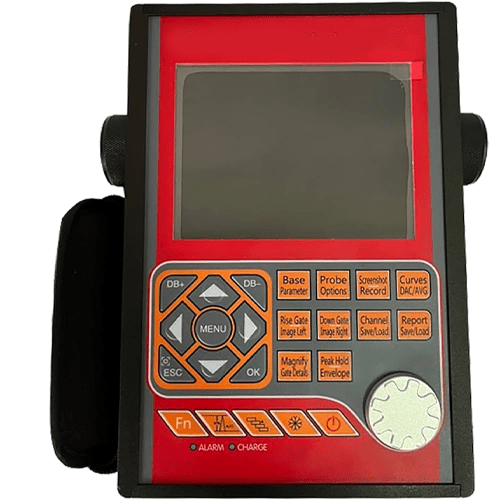

GAOTek ultrasonic flaw detector is a portable industrial digital ultrasonic flaw detector that can detect, locate, evaluate and diagnose various defects (cracks, inclusions, pores, etc.) in the workpiece quickly, conveniently, without damage, and accurately. It can be used both in the laboratory and on the engineering site. This instrument can be widely used in manufacturing, iron and steel metallurgy, metal processing, chemical industry and other fields that require defect detection and quality control. It is also widely used in online safety inspection and Life assessment in the fields of aerospace, railway transportation, boilers and pressure vessels, etc. The instrument can be widely used in locating and sizing hidden cracks, voids, disbands, and similar discontinuities in welds, forgings, billets, axles, shafts, tanks and pressure vessels, turbines, and structural components.

Features

- The core hardware is designed with ARM+FPGA

- Two fully independent gates offer a range of measurement options for signal height or distance using peak triggering

- The echo-to-echo mode allows accurate gate positioning for signals which are extremely close together

- Variable over entire displayed range

- Variable from Gate Start to end of displayed range

- Variable from 0 to 99% Full Screen Height

- Threshold positive/negative with LED Flash

Technical specifications

| Material Velocity | 1000 m/s to 20000 m/s |

| Dynamic range: | 40 dB |

| Pulse displacement | 32 dB |

| Resolving power | 40 dB |

| Pulse energy | 100 V |

| suppression | 0% to 80% |

| Pulsar | Tunable wave pulser |

| noise | < 10% |

| Vertical accuracy | 0.25% |

| Measuring Range: | 0 in to 7.57 in (0 mm to 1500 mm) |