Description

Overview

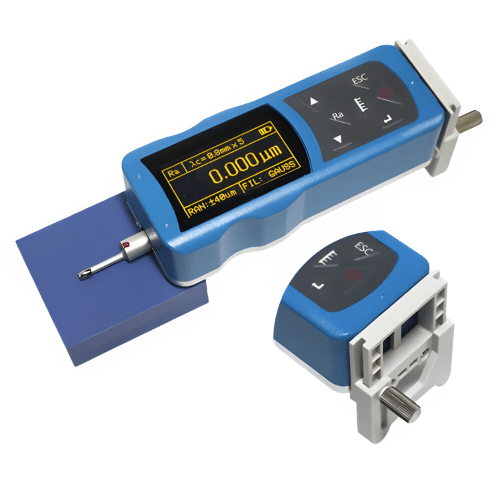

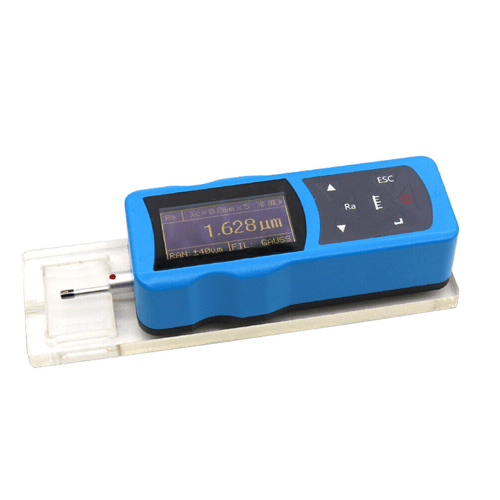

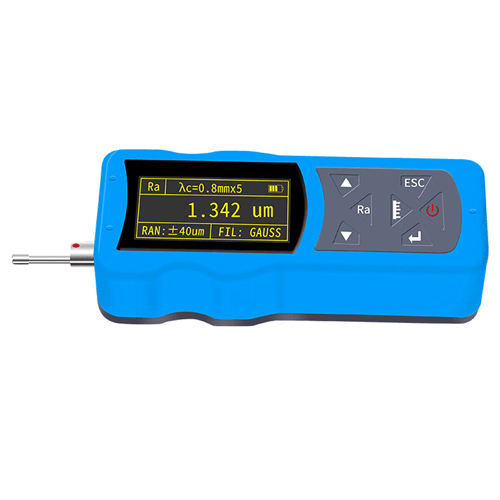

GAOTek Surface roughness tester instrument is used in metal and non-metallic parts surface roughness detection, suitable for a variety of machining parts, machining manufacturing, testing, commodity inspection, and other departments, especially for large workpieces and production lines of on-site inspection, as well as testing, measurement, commodity inspection, and other departments out of the verification, will not cause damage to the workpiece. Measurable workpiece range: plane, outer circle, cone, inner hole, groove, curved surface and other special surfaces (with suitable sensor). Its unique characteristics are that after strict temperature and humidity test, adapt to high temperature and high humidity working environment, especially the southern humid climate measurement value is not affected. High precision, stable measurement value, and leading quality in China.

Features

- Real-time clock for easy data recording

- Power-saving features, including auto sleep and shutdown

- Reliable anti-motor dead circuit, stable software design

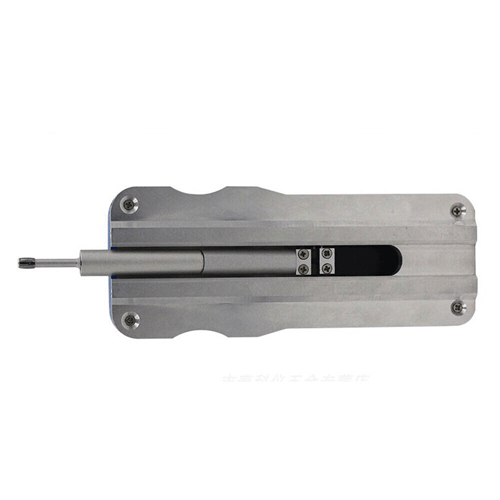

- Robust all-metal shell, portable, high reliability

- Language selection: Chinese/English

- Accessories: curved surface sensor, small hole sensor, etc

Technical Specifications

| Indication Error | ± (7 to 10) % |

| Data Storage | 100 groups |

| Size | 5.5 in x 2.2 in x 1.6 in (141 mm x 55 mm x 40 mm) |

| Net Weight | 0.9 lb (400 g) |

| Accuracy | 0.001 um |

| Max Traver Stroke | (17.5 mm) 0.7 in |

| Power Supply | 220V 50Hz |

| Indicator Error | ≤± 7% |

| Range | ±20 um, ±40 um, ±80 um |

| Point Angle | 90° |