Description

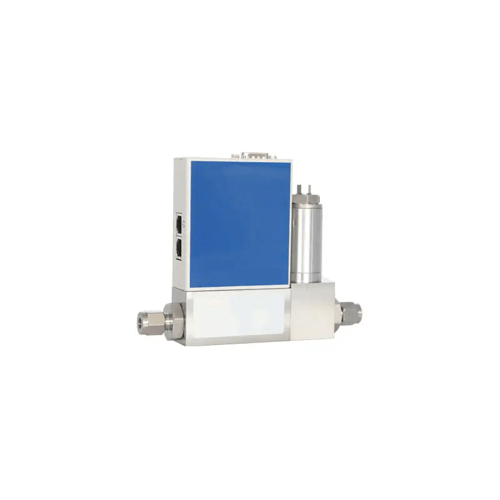

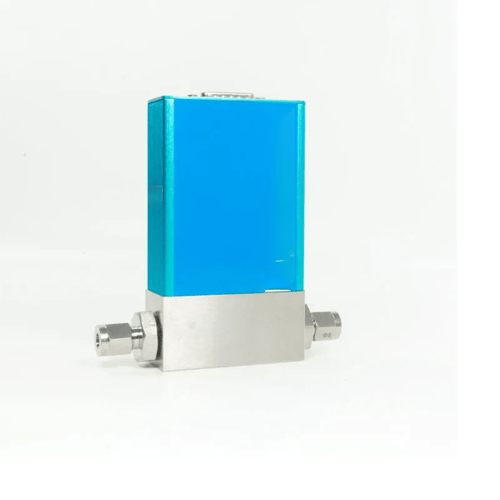

Overview

GAOTek thermal mass flow meter uses the principle of temperature difference calorimetry before and after capillary heat transfer to measure the mass flow of gas without being affected by temperature and pressure. The flow signal measured by the sensor is amplified, and then compared with the set voltage, and the difference is used to drive the control valve, and the flow through the channel is closed-loop controlled to make it equal to the set flow.

Features

- Thermal principle, fast response and high precision

- Tubular shunt, not easy to block

- Suitable for various low-pressure and high-pressure pipelines

- Short preheating time, low zero drift and high reliability

- Analog input/output can use secondary meter / flow computer

Technical Specification

| Measuring range | 100 SCCM to 30 SLM |

| Measurement and control range | Measuring range ratio 100:1 |

| Accuracy | ±0.5% F. S |

| Linear | ±0.5% F. S |

| Repeatability | ±0.2% F. S |

| Response time | Flowmeter: <0.1 sec

Flow controller: <0.2 sec |

| Digital quantity | RS 232 / 485, MODBUS protocol |

| Analog | 0 V to 5 V, 4 mA to 20 mA, 1 V to 5 V |

| Power supply | ±15 V DC, 24 V DC |

| Operating temperature | 32 °F to 122 °F (0 ℃ to 50 ℃) |

| Work pressure | Working pressure drop: 1.45 PSI (<0.01 Mpa) |

| Maximum withstand voltage | 435.1 PSI (3 MPa) / 1450.38 PSI (10 MPa) |

| Electrical connections | DB 15 hole |

| Leak rate | 1 × 10 to 9 SCCS He |

| Temperature Coefficient | ±0.025% F.S / ℃ |

| Base material | 316 L |

| Seal material | Fluorine rubber, neoprene rubber, nitrile rubber |

| Connector | 3 in ,6 in, 1/8 in, 1/4 in |