Description

Overview

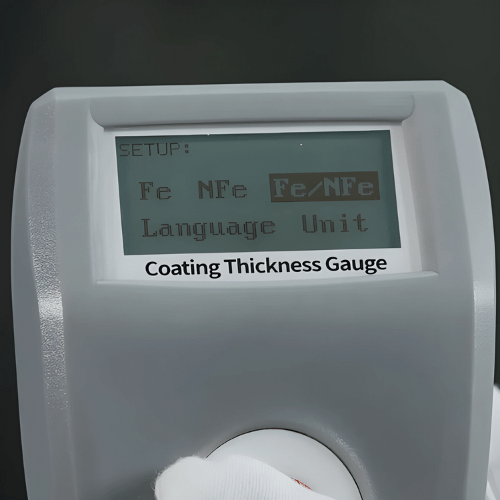

GAOTek wide measurement range coating and material thickness gauge also called coating thickness tester is an instrument that separates the host from the probe. The measuring range is 5000 μm and the meter can automatically identify the measuring substrate. This instrument uses both Hall Effect and eddy current measurement principles to measure the non-magnetic coating thickness on magnetic substrates and the non-conductive coating thickness on non-magnetic substrates. It is a dual-use instrument for both ferrous and non-ferrous substrates.

Features

- No calibration needed, simple zero adjustment for measurement

- Probe supports trigger power-on, auto substrate identification, and switching

- DC-223 tester measures materials up to 5mm thick

- Advanced digital probe technology ensures accuracy and repeatability

Technical Specifications

| Probe tip | Ruby fixed |

| Measuring principle | Fe: Hall Effect or NFe: Eddy current |

| Measuring range | Fe 0.0 μm to 5000 μm NFe 0.0 μm to 3000 μm |

| Resolution | 0.1 μm (0 μm to 99.9 μm) 1 μm (100 μm to 999 μm) 0.01 mm (1.00 mm to 5.00 mm) |

| Accuracy | ≤± (3% reading+2 μm) 0 μm to 3000 μm ≤± (5%reading+2 μm) 3000 μm to 5000 μm |

| Unit | μm / mil |

| Measuring interval | 0.5 s |

| Minimum measuring area | Ø0.98 in (Ø25 mm) |

| Minimum curvature | Convex 0.2 in (5 mm) or Concave 0.98 in (25 mm) |

| Minimum substrate thickness | Fe 0.008 in (0.2 mm) or NFe 0.002 in (0.05 mm) |

| Display | 128 × 64 dot matrix LCD |

| Power supply | 2 pcs of 1.5V AA alkaline battery |

| Range of operation temperature | 0 °F to 122 °F (0 ℃ to 50 ℃) |