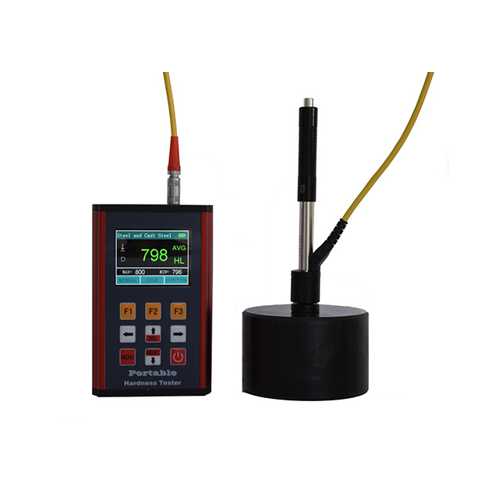

Description

Key Features

- Test values software calibration function

- Software of PC can be installed according to the requirements of user, the function will be more powerful to satisfy the more strict demands of quality control and management.

- Printer be separated from main unit and copies of testing results can be printed as required.

- Using lithium ion rechargeable batteries, Continuous working period: approx. 200 h (no back light on).

- Add New user material function, to meet the need of user can test the special material

Technical Specifications

| Color display | (320×240 TFT) with adjustable backlight. |

| Four new hardness scales | HRA, HB for D impact device of alloy tool steel; HV for cast aluminum alloy |

| Converts | To all common hardness scales(HV ,HB,HRC,HRB,HRA,HS).. |

| USB interface | Multiple communication modes are adopted to meet customized requirements of various users. |

| Equipped | with 7 types of impact devices which need not to be recalibrated when changing them, the system can identify the type of impact device automatically. |

| Storage | Max 600 groups(impact times32~1)of data can be stored at internal non volatile data storage. |

| Preset | When the tested value exceeds the limits, alarm will send out automatically to make convenient for the requirements of batch measurements. |

| Material | “cast steel” is added; HB values can be read out directly when D/DC impact device is used to measure “cast steel” work piece. |

| Application | The assembled machinery and permanently installed parts – Die cavity of molds – Heavy work piece – Failure analysis of pressure vessel, steam turbo-generator set and other equipment – Narrow testing space where work piece installed – Bearings and other parts – Cases which require the test result with normalized original recording – Material identification of the metal material warehouse – Quick tests of large range and multipoint measuring positions for heavy workpiece |