Description

Overview

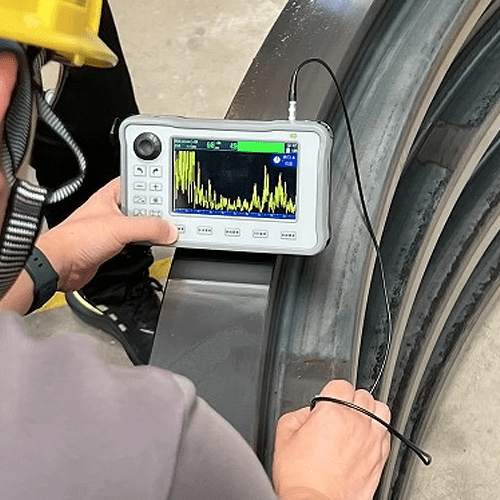

GAOTek ultrasonic depth tester has almost no resistance to ultra- sonic waves, while materials that have not undergone hardening treatment will scatter a large number of ultrasonic waves. The detection system records the backscatter signal and processes it with our electronic measuring elements. Through comprehensive automatic data evaluation, the final hardened depth of the material can be obtained.

Features

- Measurement equipment can be integrated into the production process

- The measurement accuracy is very high

- The error in determining the surface depth value is ± 0.039 in (± 0.1 mm)

- Quickly obtain measurement results

- each measurement only takes a few seconds

- Large numbers of parts can be evaluated very quickly

- By using different wedges, work pieces of different sizes can be measured

- The device can move freely

- total weight: 1.7 lb (780 g)

- Parameters can be easily adjusted according to customer requirements

Technical specification

| Measurement range | 0.02 in to 0.5 in (0.7 mm to 15 mm) |

| Measurement resolution | 0.003 in (0.1 mm) |

| Measurement repeatability | ±0.003 in (±0.1 mm) (per one location) |

| Sensibility | 80 dB or more |

| Adjustable gain | Max 120 dB Min 0.1 dB pitch |

| Vertical linearity | Within ±2.8 % |

| Horizontal linearity | Within ±0.6 % |

| Display | 5 in (12.7 cm) LCD HD screen |

| Charging time | 1.5 h |

| operating time | about 12 h |

| AC charger | AC 65 W fast charging input 100 V to 240 V ±10% 50 or 60 Hz |

| Ambient Temperature | 32 ℉ to 122 ℉ (0 ℃ to 50 ℃) (during operation) 68 ℉ to 140 ℉ (20 ℃ to 60 ℃) (during storage) |

| External dimension | 7.2 in x 4.4 in x 1.7 in (183 mm x 113 mm x 45 mm) |

| Weight | 1.7 lb (780 g) |