Description

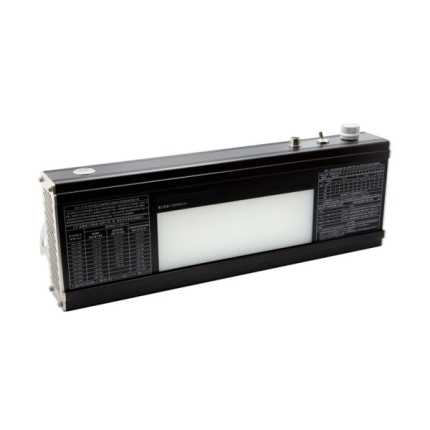

Overview

The GAOTek High accuracy AC Clamp Meter is specially designed for measuring AC current, AC leakage current, and online AC current measuring systems with a wide measuring range of 0 mA ~ 300 A. It offers modern CT-technology and digital integration technology. It has a resolution value of 10 µA. The clamp core adopts special alloy with magnetic shield technology. It is an essential tool for electrical safety testing. This clamp meter comprises of a RS-232 interface, communication cable, and software through which historical data is available for data reading, saving, and printing. This clamp meter complies with IEC1010-1, IEC1010-2-032, Pollution level 2, and CAT III (600 V) safety standards.

Key Features

- Measurement of AC current ranges from 0 mA ~ 300 A

- Upto 600 V line voltage

- Resolution value is 10 µA

- Small in size, high accuracy and flawless function

- High precision, high stability and high reliability for continuous measurement

- Offers peak holding, data holding and data storage functions

- Four Digits LCD Mode

- Online real-time monitoring, Min-AVG-MAX indication and dynamic display

- Data stored in the memory of the meter uploaded to PC via RS232 interface

- Automatic power off to lower the power consumption

- Test mode: Clamp CT and integral mode

- Free from influences of external magnetic field

- Clamp meter widely used in the fields of electricity, communications, railroad, meteorology, oil field, railroad, industries and mining establishments

- IEC1010-1, IEC1010-2-032, Pollution level 2 and CAT III (600 V) safety standards

Technical Specifications

| Test Mode | Clamp CT, Integral approach | ||

| Standards | IEC1010-1, IEC1010-2-032, Pollution level 2,CAT III (600 V) | ||

| Interface | RS-232 | ||

| Measurement Range | 0 mA ~ 300 A (AC) | ||

| Test Position | Tested wire in the jaw center. | ||

| Clamp Size | 1.38 in × 1.57 in (35 mm × 40 mm) | ||

| Resolution | 10 µA (AC) | ||

| Frequency | 50 Hz, 60 Hz (Automatic Identification) | ||

| Accuracy | 0 mA ~ 60 A | ± 1.5 % rdg ±5 dgt | 73.4 ˚F± 41˚F (23 ˚C ± 3 ˚C), below 70 % RH |

| 60 A ~ 200 A | ± 2 % rdg ±5 dgt | ||

| 200 A ~ 300 A | ± 3 % rdg ±5 dgt | ||

| Voltage Range | 600 V (AC) | ||

| Power Consumption | 5 mW | ||

| Sampling Rate | 2 times/second | ||

| Insulating Strength | AC 2 kV/rms (between core and box) | ||

| Data Memory | 99 sets | ||

| Range Shift | Automatic shift | ||

| Display Mode | 4-digits LCD Mode | ||

| Out of Range Indication | OL (indicates on LCD) | ||

| Reading Hold Indication | DH (indicates on LCD) | ||

| Auto Power-off | 5 minutes after power on | ||

| Battery | Zn-Mn dry battery,6F22, 9 V | ||

| Weight | 4.94 oz. (140 g) – with battery | ||

| Dimension | 6.89 in × 2.75 in × 1.5 in (175 mm × 70 mm × 38 mm) | ||

| LCD Dimension | 1.38 in × 0.85 in (35 mm × 21.5 mm)

Display domain: 1.26 in × 0.6 in (32 mm × 15 mm) |

||

| Operating Temperature Humidity | Below 80 % RH | ||

| Storage Temperature Humidity | Below 70 % RH | ||

| Operating Temperature | 32 ˚F to 104 ˚F (0 ˚C to +40 ˚C) | ||

| Storage Temperature | 14 ˚F to 140 ˚F (-10 ˚C to +60 ˚C) | ||

Accessories

Package includes as follows

| Item | Quantity |

| Clamp Tester | 1 pc |

| RS-232 Com cable | 1 pc |

| Battery (6F22 9 V) | 1 pc |

| Software | 1 disk |

| User manual | 1 copy |

| Warranty card/Certification | 1 copy |

Field Application:

Structure of the Leaker:

- Double input toroid

- Upper cover

- Toroid opening cover

- HOLD key

- POWER key

- LCD

- RS232 interface

- Back cover

- Battery cover

Operating method:

Start-up, Shut down:

- To start up the tester press the POWER Once switched on the power key the LCD begin to display.

- To shut down the tester press the POWER

- To reduce the battery consumption the leaker shut down automatically after start up for 5 minutes.

- LCD send the flick notes the leaker is going to shut down automatically after flickering for 30 seconds.

- By pressing POWER key when LCD is flickering the leaker will continue to work for 5 minutes.

- If the LCD displays dark after starting up, it is due to low voltage battery and change the battery immediately.

Measurement:

- Start up the meter

- Release the toroid lever to open the clamp head and clamp conductors.

- Read the LCD data. In case if the display indicates “OL mA “symbol, the current of measured line is beyond the maximum limit of this leaker, shift the gear with much higher range limit.

Peak Holding:

Press the HOLD key continuously while measuring the current more than 3 seconds, the leaker capture peak values of the current. Releasing the HOLD key return to measuring state

Hold, Storage, Access Reading and Deleting:

- By pressing HOLD key for a short time during measurement i.e.) less than 3 seconds “DH” symbol will display, the leaker hold measuring the current and the measured data automatically stored in the memory with a code

- By pressing again HOLD key release the hold state and the leaker continues its measuring.

- In case the stored data reaches 60 groups press HOLD key again “FULL” symbol denotes to storage memory is full.

- To enter into data access mode press HOLD key for long time. It display Unit 1 data storage automatically and press again the HOLD key to turn the pages of stored data. “NULL” display denotes when there is no data stored in the memory. Power off the meter to exit data access mode.

- To clean up the data, enter into data access mode by pressing HOLD key less than 3 seconds all stored data get cleaned up. When the meter displaying “dEL” symbol, it means it has finished clean-up process, and return to measuring state automatically.

Function Quick Look Up:

| POWER key short press | Power on/shutdown/exit |

| HOLD key shot press | Data holding/release/storage |

| HOLD key pressing for more than 3 seconds | Peak holding

(at measuring mode) |

| HOLD key pressing for 3 seconds | Clear data |

| HOLD key + POWER key | Data access/turn pages (HOLD key) |

Display Example and Meaning

- Leakage current measured is 0.25 mA

2. Change the battery if it indicates low

3. Leakage current measured is 0.25 mA and automatically stored unit ID is No.03

4. Access the unit 3 of the stored data

Electrical Signs:

| |

High voltage, Extremely dangerous. Operators should follow the safety rules. There would be dangers of electric shock to cause personal injuries or casualties. |

| |

Dangerous! Operators should follow the safety rules. There would be dangers of electric shock to cause personal injuries or casualties. |

| |

Attention! Operators should follow the safety rules when measuring heavy current. There would be dangers of electric shock to cause personal injuries or equipment damages might be caused. |

| In locations with difficulty to read out data, use the data holding function. If [DH] symbol displayed, discharge data holding state first, and then do the test. |