Description

Overview

GAOTek Dew Point Meter with Film Capacitive Humidity Sensor is designed using micro computer technology and developed as an intelligent trace moisture measuring instrument with best performance. Its operation is simple and it has the function of conversion among Td, RH, PPM and software upgrade. It can measure the content of trace moisture in various gases. It is applied in the industries such as petroleum, chemical, cement, metallurgy, iron and steel, desiccant manufacturers and users, semiconductor manufacturing, drying industry, food industry, plastic substrate drying, machinery manufacturing, air separation and other industries to detect the trace moisture content of various gases.

Key Features

- High performance built-in full compensation film capacitor dew-point sensor

- Zero point and slope self-calibration after start, dew point calibration by single point way for full range (patent technology)

- Sensor dry protection device (patent technology)

- Unique gas circuit design, good gas tightness and permeability, water resistance.

- Large screen TFT liquid crystal displays dew point value and the corresponding

- RH % relative humidity value, PPM moisture value

- Color touch screen control.

- Measurement data storage and query

- Intelligent power prompt, intelligent charging protection

- Lithium battery offers power supply long standby

Technical Specifications

| Measurement of Dew Point

(Dew point temperature <0℃, the output of sensor is frost point) |

-112 °F ~ 68 °F (-80 °C ~ 20 °C) |

| Typical Precision | ±35.6 °F (±2 °C) |

| Response Time (Td)

When the gas temperature is 68°F/ 20 °C |

-76 °F → -4 °F (-60 → -20 °C)

5 s (63%), 10 s (90%) |

| -4 °F → -76 °F (-20 → -60 °C)

45 s (63%), 10 min (90%) |

|

| Operation environment | |

| Temperature | -4 °F ~ 140 °F (-20 °C ~ 60 °C) |

| Relative Humidity | 0 ~ 100%RH(non condensation) |

| Pressure | 0 ~ 20 bar |

| Response | 5 -15 s |

| Parameters of complete appliance | |

| Working Flow | no influence |

| Power Supply | Built-in lithium battery (7.2V 8000mAh), AC/DC |

| Battery | >10 h |

| Digital Output | RS232C |

| Dimensions | 11.8 in × 11 in × 5.9 in

(300 mm × 280 mm × 150 mm) |

| Weight | About 11 lbs. (5 kg) |

Additional Information

Packing List

| No. | Commodity | Quantity | Description |

| 1 | Dew Point Meter with Film Capacitive Humidity Sensor | 1 set | Measuring micro-water under normal pressure |

Random Accessories

| 2 | Charger | 1 | Charging the dew-point meter |

| 3 | Φ4 measuring tube | 5 meters | Special PTFE measuring tube |

| 4 | Special fast plug | 1 | Connecting measuring tube with meter |

| 5 | Φ4 flexible pipe | 5 meters | Let out exhaust to safe area (blue) |

| 6 | PTFE tape | 1 volume | For sealing |

| 7 | Bottles of gas fittings | 1 | Measuring bottles of gas on decompressing table |

| 8 | Regulating valve

(with pressure gauge) |

1 | Reduce pressure by connecting switch connector |

| 9 | Serial line | 1 | |

| 10 | Instruction Manual | 1 | |

| 11 | Test Report | 1 | |

| 12 | Certification | 1 | |

| 13 | Meter box | 1 |

Optional Accessories

| 14 | Infrared printer | 1 | |

| 15 | Printer Charger | 1 |

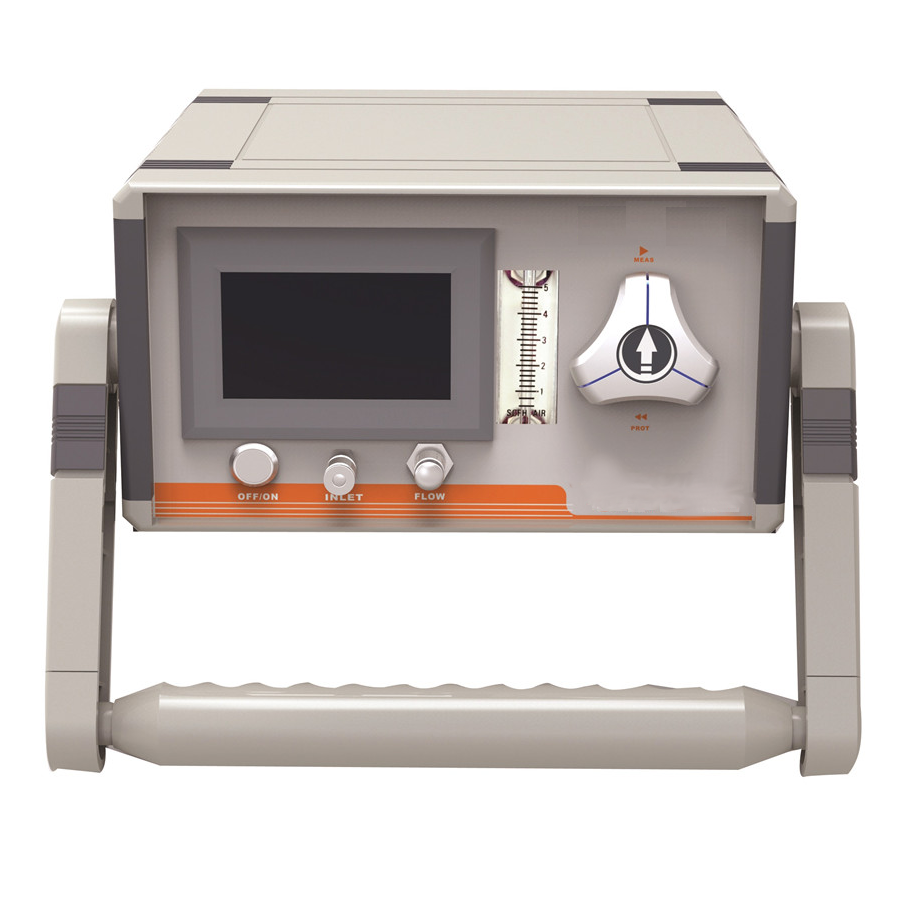

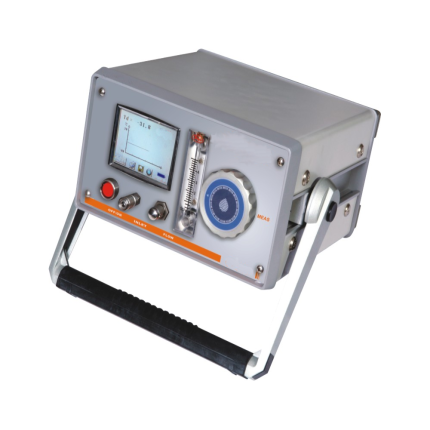

OPERATION PANEL

- Touch display

- Float flow meter

- Protection knob, the arrow points MEAS during measurement, or otherwise it points PROT

- On/Off button

- Gas inlet (rapid inserting interface)

- Gas flow control valve (changing gas flow by adjusting this valve)

BACK PANEL

- Function selector

- Gas outlet

- RS-232 serial interface

- Recharging interface

OPERATING INSTRUCTIONS

Introduction to Starting and Test Interface

Turn on the power supply, start the interface the screen display as follows.The system will do initial setting and memory formatting.

After the startup, meter display is shown in the Figure

Display of main interface includes system time, battery level, measurement data, corresponding curve, menu and storage button. Startup system will do automatic calibration, and the words “automatic calibration” will appear about 1 minute later upon startup. Normally, the automatic calibration will end about 8 minutes later, and the “Finish!” will appear, but it will disappear rapidly. During this period, all of the data relevant to humidity are invalid and unavailable.

Note: If the conditions are not met, the sensing unit will do automatic calibration all the time, until the calibration is passed. If the calibration takes a longer time, please supply the gas with the dew-point temperature of about -30 °C to provide a better automatic calibration condition for the sensing unit.

Click ![]() icon in the interface , current measurement data (including dew-point temperature Td, relative humidity RH, temperature T, and moisture content PPM) will be stored by date. If the storage is successful, the icon will turn green and then gray.

icon in the interface , current measurement data (including dew-point temperature Td, relative humidity RH, temperature T, and moisture content PPM) will be stored by date. If the storage is successful, the icon will turn green and then gray.

Click ![]() icon in the interface , current measurement data (including measuring time, dew-point temperature Td, relative humidity RH, moisture content PPM, temperature T) will be printed through optional external infrared printer. The infrared printer adopts portable thermal printer. Please note that the infrared transceiver of the printer should correspond correctly to the infrared transceiver of the meter, while the distance is not more than 1 meter. If the data is sent successfully, the icon will turn green and then gray.

icon in the interface , current measurement data (including measuring time, dew-point temperature Td, relative humidity RH, moisture content PPM, temperature T) will be printed through optional external infrared printer. The infrared printer adopts portable thermal printer. Please note that the infrared transceiver of the printer should correspond correctly to the infrared transceiver of the meter, while the distance is not more than 1 meter. If the data is sent successfully, the icon will turn green and then gray.

Meter Settings

Functions and use of menu setting:

Click ![]() icon, then the system displays a numeric input interface which requires a password

icon, then the system displays a numeric input interface which requires a password

Click the corresponding figures to input password. The password has four digits, if more than four are input; the system would get the last four digits concealed automatically. Press “ENTER” to confirm after inputting. If the password is right, the system will enter the menu setting interface; and if the password is wrong, it will return to the main interface. (Note: the initial password of the meter when leaving factory is “0000” and users can make a change).

If the password input is right, the system will enter the menu setting interface, which has four menus, i.e. the password change, time setting, storage query and language, containing all the setting and control of the corresponding parameter of the whole system.

Password Modification

Password modified is the password that users set by themselves to enter the menu setting system. The password for the instruments upon delivery is 0000. If change is needed, the user must enter the old password correctly.Click the gray box area “Enter the old password”; and then enter the password entry interface.After entering the old password, press “OK” icon to return the interface . Then click “OK”. If the password input is wrong, the system will prompt red warning as “Wrong password! Enter again!” If the password input is correct,it displays as follows

Enter the new password in the same way . If the format is correct, it shows yellow reminder as “New password saved!”.

Storage Query

Storage query is to examine the measurement records saved by the instrument for inspection. Data storage of this system is done in time sequence. The storage record every day is put in one file which is named in time format of “Year-Month-Day”.

Steps for querying into the data on some day are as follows:

Click the corresponding file and it will turn blue, showing it is selected.Only one file can be selected at a time.

Click ![]() and the system will call out the first piece of record measured on the day and show at the same time the storage space, the number of total pages, the current page and the value of the first piece of parameter.

and the system will call out the first piece of record measured on the day and show at the same time the storage space, the number of total pages, the current page and the value of the first piece of parameter.

Click “Up” and “Down” to view records; click “printer” icon to print the data on this page, click “Back” to return to upper interface. In this interface, the four icons on the left side are inactive.

In case of excessive files, the search method can be used to look up the data on some day.

Click the research input box, and date input interface will pop up . Then input the time to be enquired, the time format is: month with two digits, day with two digits and year with four digits, namely, “YYYYMMDD”. For instance, if we want to inquire the data on “2009-09-14”, just input “20090914” in numeric keypad, then click “Enter”, the system returns to the interface

Click “Start”, and the system will research this file automatically. If the file is not included in the storage, the system will show yellow reminder “No storage record!” For instance, if the file that we stored has no this file “2012-03-04”, but we input “20120304” into the search input box to search it,

If the file to be inquired exists in the storage, it will be shown. For instance, if we want to search the file “2013-07-12”, the system will show Figure

If you want to delete files, the steps are as follows:

Select the file to be deleted, and its name turns blue, showing this file is selected (only one file can be selected at a time).

Click ![]() in the storage interface, and this file is deleted.

in the storage interface, and this file is deleted.

The steps for formatting the whole storage are as follows:

Click ![]() and the system will show the interface below,

and the system will show the interface below,

Click “YES” icon, the system will perform format operation, as shown in Figure 3-16. Users need to wait for a few minutes, to find the not responding time. If you do not format, you can click “NO” to return to storage query interface.

There are at most 9 files on a screen in the storage query interface. If the file number is more than 9, users can click on the scroll bar to scroll.

Instrument Calibration

This instrument can do automatic calibration for low humidity; and high humanity is calibrated with serial line on computers (If the gas to be detected is low humidity gas, the meter will do automatic calibration in use.) In case the instrument requires high humidity calibration or comes to the regulated calibration cycle (once per year), returning it to the factory for calibration is recommended.

Preparation before calibration

Calibration of humidity instrument must be prepared with the instruments and equipments below:

- Standard meter

- Humidity generator

- High purity nitrogen

Note: If the necessary instruments and equipments for the calibration above are not available on the site, the meter can be returned to the factory for calibration.

System figure for calibration

Note: Use Teflon tube and polypropylene tube as the sampling tube. Ordinary steel pipe and plastic tube are prohibited.

Calibration steps

- Connect the Dew-point Meter to computers with serial cable;

- Rotate the functional lock to “CAL” state with key;

- Enter “Super Terminal” on windows platform of computers.

The steps are: “Start”, “Programs”, “Accessories”, “Communication”, “Super Terminal”, “Select Serial Port”, “Set Parameters(set of serial port)”;

Setting of serial port:

Baud rate: 2,400

Data bit: 8

Check bit: None

Stop bit: 1 - Supply standard gas to gas inlet, use the order REG OFF and DCAL OFF to turn off regaining and automatic calibration;

- After readings turn stable, read out the actual data by the order R<CR> and record the actual readings (Rh actual);

- Calculate differential value according to the reference value of data and the actual humidity, RH diff=RH ref-Rh actual;

- Provide the order: CRH 0 0 RH ref RH diff<CR>

Remark: RH ref: reference humidity (%RH), RH diff: difference of reference value and actual humidity (%RH). - Use the order REG ON and DCAL ON to open regaining and automatic calibration;

- Turn off power supply at once; and now, the calibration has been performed!

- Finally, re-use the key to rotate the calibration lock to “WORK” state, and the calibration is completed.

Storage: Under transportation condition, equipment’s shall be kept in environment with temperature of 32 °F ~ 122 °F (0 °C ~ +50 °C) and absolute humidity <85% and without oily, corrosive gas or dust in the air.

Printing Function (Optional)

Infrared printer is an optional accessory. Please keep the infrared ray receiver of the printer directly opposite the infrared emission port on the side of the product during printing. The suggesting distance is less than 60cm.

Printing paper: the width is 57mm; the diameter of stock form is 40mm.

Quality assurance

Before all the products of GAOTek leave the factory, they have been proportionally adjusted and debugged according to requirements of customers. They are also conformed according to related national standards and industrial standards after strict inspection.

We guarantee: products of our company whoever buy, will be repaired and maintained for free within one year since the date of purchase of the product. Any damages or problems under the following situations are excluded from free warranty service:

- Accidents, disasters or improper installation or application

- Unauthorized disassembly and modification of products

- Use under environmental requirements disagrees with products