Description

Overview

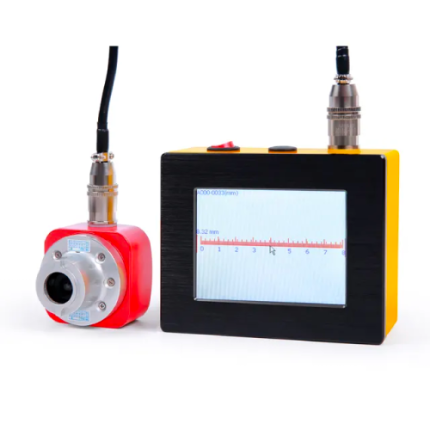

GAOTek metal material flaw crack detector features can quickly, non-destructively, and accurately detect various defects (cracks, inclusions, blowholes, etc.) inside the workpiece. The product is unique in design, easy to operate and durable. It adopts all-Chinese true color liquid crystal display. Different color schemes can be selected according to the environment. The brightness of liquid crystal can be adjusted under strong outdoor light. Master-slave menu design, with digital shuttle wheel, easy to operate, leading technology. It is widely used in aerospace, railway transportation, building steel structures, boiler pressure vessels and other fields. It is a necessary professional precision instrument for defect detection, quality control, in-service safety monitoring and life evaluation in railway, shipbuilding, metallurgy, chemical industry, petroleum and other industries.

Features

- Lower price but high quality, worthy

- Accurate, stable, and good experience

- Conform to Grade 2 working machine standards

- Easy to operate, refuse to wait

- QC measurement mode for auto qualification

- Support PC software to generate test reports

- Smooth appearance, comfortable grip

- Long battery life, energy-saving and environmental

Technical Specifications

| Working principle | Ultrasonic |

| Working frequency | 0.2 MHz to 20 MHz |

| Pulse Width | Square wave width 30 ns to 1000 ns adjustable, step 0.1ns |

| Detection range | 0 to 14000 (Steel longitudinal wave) |

| Pulse shift | -45 to 1000(steel longitudinal wave) |

| Material sound velocity | 300 m/s to 15000 m/s |

| Detection method | Negative wave, positive wave, two-way wave, filter, RF wave |

| Gain adjustment | 0 dB to 110 dB: 0.1/1/2/6 step adjustment |

| Thickness measurement function | non |

| WIFI/HDMI/digital filtering wave | non |

| Sluice gate | Incoming gate, loss gate, single gate reading, double gate reading |

| DAC, AVG Function | DAC curve, AVG curve |

| Attenuator error | Every 12 dB to ±1 dB |

| Vertical linearity error | ≤3% |