Description

Overview

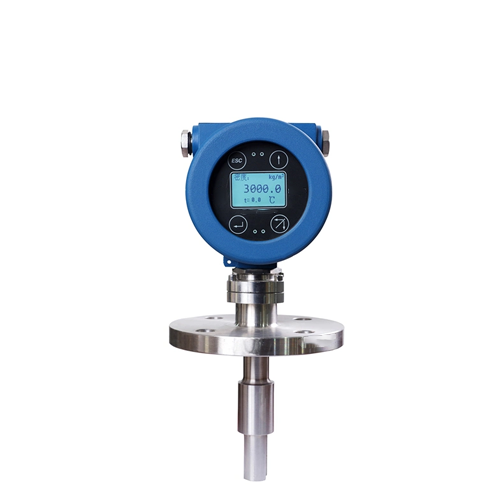

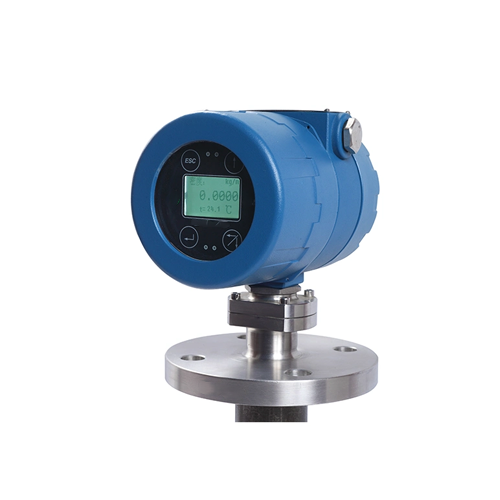

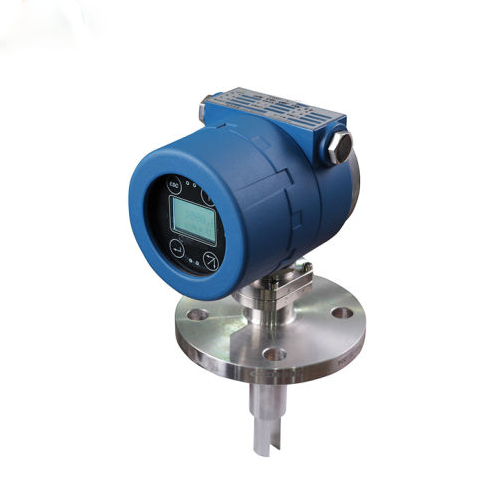

GAOTEK insertion density meter could apply the on-line density testing. It could be applied in the product process controlling based on the basic parameters of density, or the mass controlling system as the solid percentage or the concentration for references. Typical Industries include petroleum chemical industry, wine industry, food industry, pharmaceutical industry, and mineral processing, (for example clay, Carbonate Carbon, Silicate, etc.).

Features

- Liquid Density Measurement: The meter is specifically designed for measuring the density of fuel oil and other liquids. It provides accurate density readings, which are crucial for quality control and fuel blending applications.

- Vibration Tuning Fork Technology: The meter utilizes a vibration tuning fork sensor to measure the liquid density. The tuning fork vibrates at a specific frequency that changes based on the density of the liquid, allowing for precise density measurements.

- Digital Display: The meter is equipped with a digital display that shows real-time density readings in a clear and easy-to-read format. It allows for quick and accurate data interpretation.

- Wide Density Range: It offers a wide density range capability, allowing it to measure a broad spectrum of fuel oil densities typically encountered in various industrial applications.

- Quick and Non-Destructive Measurement: The meter provides fast and non-destructive density measurements. It does not require sample extraction or contact with the liquid, making it convenient and efficient for routine density checks.

- Temperature Compensation: It may feature temperature compensation functionality, accounting for changes in temperature that can affect density readings. This ensures accurate density measurements even in varying temperature conditions.

- User-Friendly Interface: The meter is designed with a user-friendly interface, making it easy to operate and navigate through different settings and options.

- Data Storage and Export: Some models may offer built-in memory to store measurement data. They may also provide data export options, allowing users to transfer density readings to a computer or external device for further analysis or record-keeping.

- Compact and Portable Design: The meter is compact and portable, making it suitable for both laboratory and field use. Its handheld design allows for easy handling and mobility during density measurements.

Technical Specifications

| Density Range | 0.5 – 2.5 g /cc (500 – 2500 kg/m3),other density range can be special ordered |

| Measurement Accuracy | ± 0.002 g /cc (± 2 kg/m3); ± 0.001 g /cc (± 1 kg/m3) |

| Repeatability | 68 °F to 392 °F (20 °C to 200 ºC), other temperature range can be special ordered |

| Pressure Rating | 0 to 4 MPa, other pressure range can be special ordered |

| Viscosity Range | 0 – 20000 cP |

| Temperature Effect | Less than 0.1 kg/m3/ºC (After Calibration) |

| Impact from Pressure | Negligible |

| Built-in Temperature Sensor | PT100 |

| Wetted Parts | Stainless steel 316L Hastelloy alloy |

| Tine Finish | Standard, PFA coated, or Electro-polished |

| Power supply | 24 V DC, ≥ 500 mA/ 220 V AC |

| Outputs | 4 to 20 mA,0 to 1000 Hz, RS485 Modbus RTU |

| Process connection | Flange, chuck connection, etc. Other connection can be special ordered |

| Outer Covering | Aluminum alloy |