Description

Overview

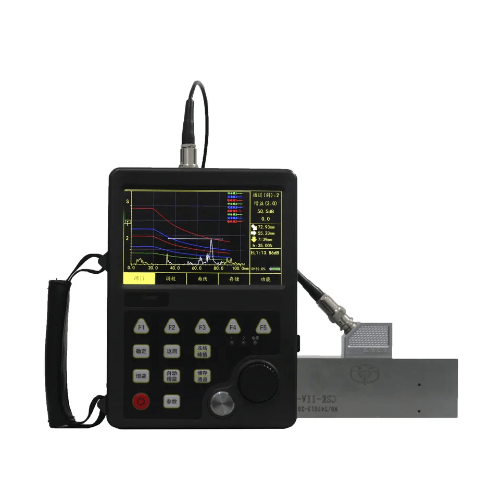

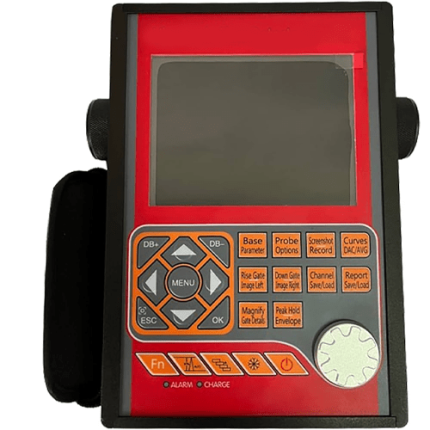

GAOTek coating flaw detector uses some modern high and new technologies, such as ultrasonic flaw detection, thickness measurement, computer, electronic, die and process, and realized the perfect combination of these high and new technologies. For the industry to provide a superior performance, more powerful detection thickness measurement machine.

Features

- Includes a thickness gauge calibration test with separate thickness operation

- Features wireless network function for mobile Internet access

- Equipped with digital filtering for precise frequency band selection

- Intuitive defect display with B scan functionality

- HDMI interface for connecting monitors and projectors

- Card interface for expandable storage capacity and convenient data transfer

- Built in 11 sets of national standards and compatibility with standards

- Offers dynamic waveform storage, playback, and screen copying

- Power saving design with over 10 hours of continuous operation

Technical Specifications

| Transmit Pulse | Square wave, transmit voltage 25 V to 400 V (step 25 V), width 30 ns to 1000 ns (step 0.1 ns, 1.0 ns, 10 ns, 100 ns) |

| Impedance Matching | 50 Ω, 100 Ω, 150 Ω, 400 Ω |

| Frequency Band Selection | 0.5 MHz to 4 MHz, 2 MHz to 8 MHz, 0.5 MHz to 20 MHz |

| Gain Range | 0.0 dB to 110.0 dB (step 0.1 dB, 1.0 dB, 2.0 dB, 6.0 dB) |

| Probe Bias | 0.00 μs to 100.00 μs (step 0.01 μs, 0.1 μs, 1.0 μs, 10 μs ) |

| Vertical Linearity | ≤3% |

| Horizontal Linearity | ≤0.3% |

| Resolution | >36 dB |

| Dynamic Range | ≥32 dB |

| Inhibition | 0% to 99%, Does not affect the linearity and gain |

| RF Output Impedance | 50 Ω |

| Electric Noise Level | <10% |

| Interface | Q9 probe interface |

| Power Supply | Large capacity, 220 V AC (with power adapter) |

| Working Time | More than 10 Hrs |

| Relative Humidity | 20% RH to 95 % RH |

| Ambient Temperature | 14 °F to 104 °F (-10 ℃ to 40 ℃) |

| Dimension | 7.09 in x 5.12 in x 1.57 in (180 mm x 130 mm x 40 mm) |

| Weight | 1.65 lb (0.75 kg) |