Description

Overview

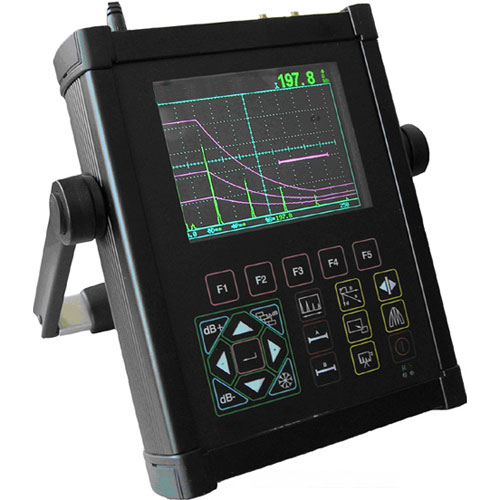

GAOTek HUT800B is a portable industrial nondestructive flaw detector, which can rapidly, easily and accurately inspect, locate, evaluate and diagnose various defects (crack, inclusion and pinhole, etc.) in a work piece without destruction. It can be used both in a lab and field. The instrument can be widely used in any fields that need defect inspection and quality controlling e.g., manufacturing industry, iron & steel metallurgical industry, metalworking, chemical industry, etc., also be broadly used in the active safety inspection and service life evaluation in such fields as aerospace, railway transportation and boiler pressure vessels, etc. It is an essential instrument for non-destructive inspection industry.

Features

- High precision quantified and positioning, catering to near and longer distance testing requirements.

- Near to field blind small to meet the small diameter, thin to walled tube testing requirements.

- Automatic calibration: one button automatic calibration for “zero,” “K value,” “forward,” and “sound speed of materials” of the automatic test probe.

- Automated display precise flaw location (Depth d, level p, distance s, amplitude, equivalent dB, apertures).

- Automated switch three staff gauge (Depth d, level p, distance s).

- Automated gain, Peak Hold, and Peak Memory, enhancing detection efficiency.

- Automatic recording of testing process with dynamic playback (unlimited).

- Φ value calculation: automatic identification of deficiencies in straight probe forging testing, highest wave converted apertures value.

- 100 independent detection channels (expandable), freely input any inspection standard, scene work without test block.

- Memory and playback of 500 A sweep waveforms and data.

- DAC, AVG, TCG curves can be sectioned with unrestricted sampling points, allowing correction and compensation.

- Selection from 14 built inspection standards or input any inspection standard freely.

- Adjustable pulse width and intensity.

- B scan function, providing clear depiction of flaws’ longitudinal cross-sectional shape.

- Computer communication for data management, Excel export, A4 paper inspection report.

- IP65 standard aluminum magnesium alloy shell, durable, waterproof, dustproof, excellent anti interference ability.

- Instrument system upgradable using PC and communication software.

- 260,000 true color super bright large screen with adjustable brightness for various lighting conditions.

- High performance environmental safety lithium battery offers 10 hours of continuous work.

- Real time clock record: tracks and stores real time testing date and time.

- Power failure protection ensures stored data is retained.

- Inspection parameters can be automatically tested or preset.

- Digital inhibition without affecting gain and linearity.

- Gain Compensation corrects Db attenuation due to surface roughness, curved surface, thick work piece long distance testing, and other factors.

- PC end communication software supports soft keyboard operation, computer control of flaw detection host.

Technical Specifications

| Range of scanning (mm) | 0 in x 393.70 in (0 mm x 10000 mm) |

| Frequency range | 0.4MHz to 20MHz |

| Vertical linearity error | ≤3% |

| Horizontal linear error | ≤0.1% |

| Gain control | 110dB |

| Flaw detection sensitivity | ≥ 62dB (deep 7.87 in (200 mm) 2 flat bottomed hole) |

| Resolution | >40dB (5N20) |

| Dynamic Range | ≥32dB |

| Noise level | <8% |

| Repeat transmitting frequency | 100 to 1000Hz |

| Sound Velocity Range | 100 to 15000 (m/s) |

| Working methods | Single crystal testing, double crystal testing, penetration testing |

| Digital suppression | (0 to 80) %, not affect the linearity and gain |

| Working Hours | More than 10 hours of continuous work (lithium battery) |

| Ambient temperature | -4°F to 158°F (-20°C to 70°C) (Reference value) |

| Relative humidity | 20 % RH to 95 % RH |

| Dimensions | 9.37 in x 6.10 in x 1.81 in (238 mm x 155 mm x 46 mm) |

| Weight | 2.20462 lb (1.0KG) |