Description

Overview

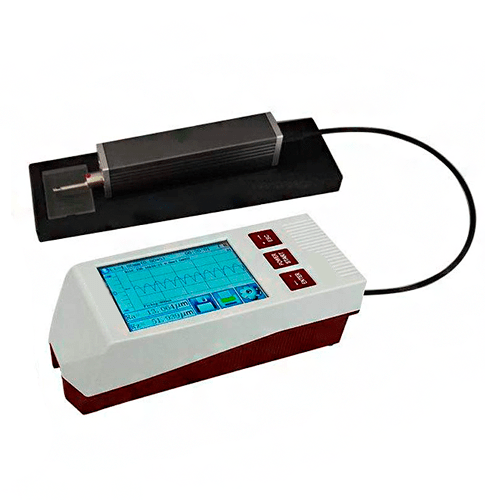

GAOTek Surface Roughness Tester is a high accuracy instrument for measuring surface roughness. It can be used on a variety of machine parts and operates on various surfaces, not only flat but also outer cone, outer cylinder, curved, pinholes, grooves, recesses grooves and axle etc. It complies with international standards ISO, DIN, ANSI, JIS.

Features

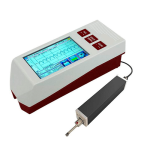

- Compact, lightweight, ergonomic design for easy operation

- Flexible drive unit storage and split option

- DSP chip for high-speed, low-power control and data processing

- Measures various parameters with optional extras

- Measurement range up to 160μm (optional 320μm)

- 5 in (8.89 cm) color LCD touch screen for intuitive display

- Operate with buttons or touch screen

- Mobile APP operation and Bluetooth printing support

- Built-in rechargeable battery with long life

- Large data storage capacity for 100 items

- Real-time clock, auto sleep, and power-saving features

- Reliable circuit design to prevent motor issues

- Language switch between Chinese and English

- Print all or user-set parameters easily

Technical Specifications

| Measurement Range | 1. The Z axis (vertical): ±80 μm or ±160 µm (enhanced model) 2. The X axis (Transverse) : 0.7 in (20 mm) 3. Parameter Range: a. Ra, Rq: 0.005 μm to 30 μm b. Rz, R3z, Ry, Rt, Rp, Rm: 0.02 μm to 320 μm c. Sk : 0 to 100% d. S, Sm : 0.03 in (1 mm) e. tp : 0 to 100% |

| Resolution | The Z axis (vertical): a. 0.01 μm or ±20 μm b. 0.02 μm or ±40 μm c. 0.04 μm or ±80 μm d. 0.08 μm or ±160 μm |

| Measurement item | 1. Parameter: Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, Rz (JIS), Rs, Rsk, Rsm, Rku, Rmr, Ry (JIS); (enhanced model with extra Rmax, RPc, Rk, Rpk, Rvk, Mr1, Mr2) 2. Standard: ISO, ANSI, DIN, JIS 3. Graphic: bearing area curve, roughness profile, primary profile |

| The sampling length (lr) | 0.009 in, 0.03 in, 0.09 in (0.25 mm, 0.8 mm, 2.5 mm) |

| Assessment length (ln) | Ln = lr × n n = 1 to 5 |

| Sensor | 1. Measuring method: skidded 2. Stylus tip: diamond, 90 cone angle, 5 μmR 3. Force: < 4 mN 4. Skid part: hard alloy, skid radius of curvature: 1.5 in (40 mm) 5. Traversing speed: lr = 0.25: Vt = 0.135 mm/s lr = 0.8: Vt = 0.5 mm/s lr = 2.5: Vt = 1 mm/s Return: Vt = 1 mm/s |

| Accuracy | Less than ± 10 % |

| Repeatability | Less than 6% |

| Power supply | DC 5 V, 800 mA |

| Working Environment | Temperature: – 4 °F to 104 °F (- 20 ℃ to 40 ℃); Humidity: < 90 % |

| Outline dimension | Main unit: 2.5 in x 2.0 in x 6.2 in (64 mm x 53 mm x 160 mm) ; drive: 0.9 in x 1.0 in x 4.5 in (23 mm x 27 mm x 115 mm) |

| Weight | 0.8 lb (380 g) |