Structural Thickness Gauge Testers

GAO’s structural thickness gauge testers, also known as thickness gauges or thickness testers, are instruments used to measure the thickness or distance between two surfaces of a material. They are widely employed in industries such as manufacturing, construction, automotive, aerospace, and quality control to determine the thickness of materials like metal, plastic, glass, coatings, and more.

GAO’s structural thickness gauge testers are composed of a transducer, display, measurement circuitry, calibration controls, power source, data storage and connectivity, protective casing, control buttons or keypads, and the encoder’s mechanism.

The other common names of thickness gauges are thickness measurement devices, depth gauges, material thickness testers, micrometer gauges, ultrasonic thickness meters, calipers, thickness inspection tools, gauge micrometers, material depth analyzers, ultrasonic material gauges, thickness measuring instruments, depth assessment devices, gauge calipers, material thickness analyzers, and ultrasonic depth meters.

Ultrasonic Thickness Gauge (Couplant, Auto-Calibrate)

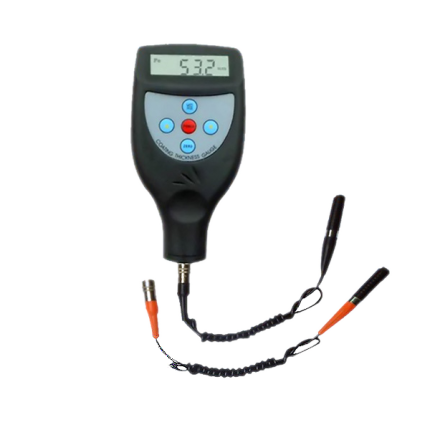

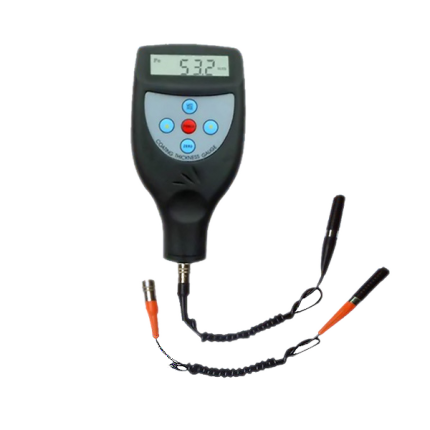

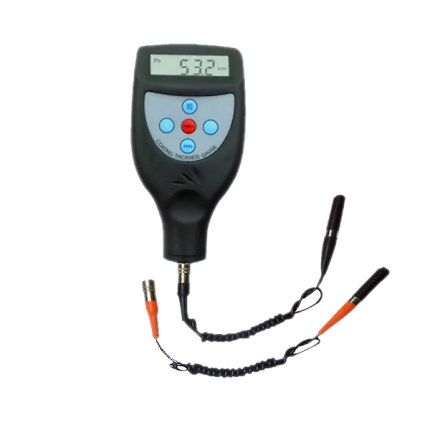

Coating Thickness Gauge with Iron-Based(Non-Ferrous)

Coating Thickness Gauge With C Pad (Eddy Current)

Coating Thickness Tester with Data Log (Auto Power-Off)

Thickness Gauge With Beep (Metric and Imperial)

Coating Thickness Gauge with 2 Work Pattern (Statistic Data)

Coating Thickness Gauge with Non-Magnetic Cover (Light Weight)

Coating Thickness Gauge with Unique Algorithm (Wireless)

A/B scan Ultrasonic Thickness Gauge (Digitized Thickness)

GAO Tek’s structural thickness gauge testers have the following functions:

- Thickness Measurement - The primary function of GAO's structural thickness gauge tester is to measure the thickness of various materials. We provide accurate and precise readings of the distance between two surfaces of a material, allowing for quality control, inspection, and assessment of material thickness.

- Quality Control and Inspection - They enable the verification of material thickness during manufacturing to ensure compliance with specified thickness tolerances and standards. By detecting deviations from the desired thickness, we help identify potential defects or irregularities in the material.

- Multiple Measurement Modes - GAO structural thickness gauge testers offer different measurement modes to accommodate various materials and measurement scenarios. Common modes include single-point mode (for measuring thickness at a specific location), multiple-point mode (for capturing thickness readings at multiple points), and scan mode (for continuous thickness measurements along a surface).

- Data Storage and Recall - Many of our structural thickness gauge testers have built-in memory or storage capabilities. This allows operators to store measurement data, calibration information, and other relevant details. Stored data can be easily recalled and reviewed on the device's display or transferred to a computer for further analysis.

- Calibration and Material Velocity Adjustment - Our structural thickness gauge testers typically provide calibration options to ensure accurate measurements. We can calibrate the gauge using known thickness standards or by adjusting the material velocity setting to match the specific material being measured.

GAO Tek’s structural thickness gauge testers are rugged, versatile, and precise measurement instruments. They comply with applicable industry standards such as ASTM E797, ISO 2808, ISO 2063, ASME Section V, EN 15317, NACE SP0285, BS EN 15317, and MIL-STD-1537.

Our structural thickness gauge testers help our customers comply with relevant U.S. government regulations such as:

- OSHA Regulations

- FDA Regulations

- NIST Handbook 44

- EPA Regulations

- DOT Regulations

Our structural thickness gauge testers help our clients comply with relevant Canadian government regulations such as:

- Measurement Canada

- Health Canada Regulations

- Environment and Climate Change Canada Regulations

- Transportation Regulations

- Canadian Nuclear Safety Commission (CNSC) Regulations

Our structural thickness gauge testers have the following applications:

- Manufacturing and Quality Control - GAO structural thickness gauge testers are used in manufacturing industries to ensure consistent product quality. We provide reliable instruments for processes. Our instruments accurately measure and monitor material thickness to ensure adherence to specifications and quality standards.

- Non-Destructive Testing (NDT) - Our structural thickness gauge testers are integral to non-destructive testing methods. We provide instruments that measure material thickness without causing damage, enabling inspections for structural integrity, corrosion detection, and quality assessment in industries.

- Automotive Industry - In the automotive sector, our structural thickness gauge testers are used for various purposes. We offer instruments that accurately measure the thickness of vehicle body panels, paint coatings, glass, and other automotive components. This ensures proper manufacturing, assembly, and compliance with safety and performance standards.

- Marine and Shipbuilding - Our structural thickness gauge testers are used in the shipbuilding and maritime industries. We provide instruments for measuring the thickness of hulls, tanks, pipes, and coatings on ships and offshore structures. Our instruments ensure structural integrity, reduce corrosion, and comply with safety regulations.

Our structural thickness gauge testers can be shipped overnight within the continental U.S. and Canada, and can be shipped globally.