Description

Features

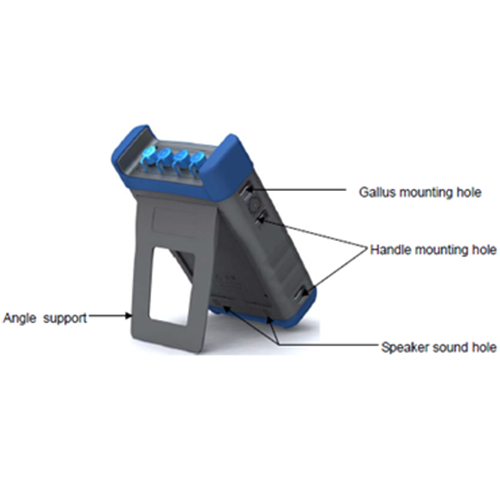

- Handheld, lightweight and convenience for carrying

- Advanced antireflection LCD, visible display interface even outdoor

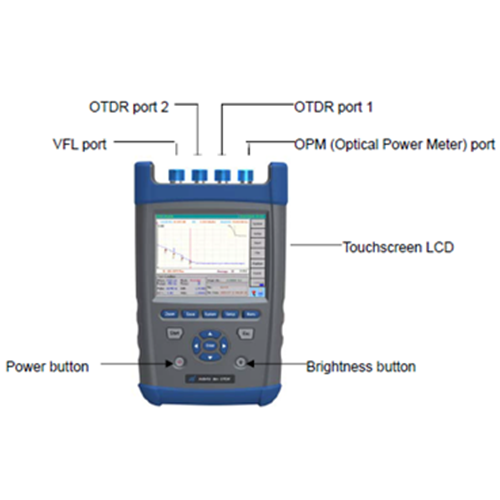

- duplex operation mode of touchscreen and key-press

- 8 m extra-short event dead zone, easy to test optical fiber jumper

- 45 dB high dynamic range, 256 k data sampling points

- Communication light auto monitoring function

- Remote function via Ethernet

- Double USB ports for connection of external USB disk & printer and communication with PC via Sync Active software

- WinCE windows operating system, an operating interface with many languages;

- Built-in optional visual fault locator (VFL), optical power meter, optical source, audio detection, etc. functions

- Universal FC/PC,FC/SC,FC/ST connector type, it is convenient for surface cleaning

- The optical output connector of the device can be replaced randomly which makes cleaning of optical fiber end face convenient

- Large capacity lithium battery allows the instrument to work for more than 8 hours

Technical Specifications

| Optical Output Port Connector | FC-PC (Standard) |

| Screen | 640 in x 480 6.4 in color LCD (Touch-screen) |

| Range | Single mode: 0.24 mi, 0.49 mi, 0.99 mi, 1.98 mi, 4.97 mi, 9.94 mi, 19.89 mi 39.76 mi, 78.53 mi, 34.79 mi, 318.142 mi (0.4 km, 0.8 km, 1.6 km, 3.2 km, 8 km, 16 km, 32 km, 64 km, 128 km, 256 km, 512 km)

Multi-mode: 0.24 ml, 0.49 ml, 0.99 ml, 1.98 ml, 3.97 ml, 9.94 ml, 19.89 mi (0.4 km, 0.8 km, 1.6 km, 3.2 km, 6.4 km, 16 km, 32 km (850 nm) |

| Pulse Width | Single mode: 5 ns, 10 ns, 30 ns, 80 ns, 160 ns, 320 ns, 640 ns, 1,280 ns, 2,560 ns, 10,240 ns, 20,480 ns

Multi-mode: 5 ns, 10 ns, 30 ns, 80 ns, 160 ns, 320 ns, 640 ns, 1,280 ns (850 nm) |

| Refractive Index of Optical Fiber Group | Regulate within range of 1.00000 -2.00000 |

| Fiber Cable’s Coefficient of Correction | Regulate within range of 0.80000 – 1.00000 |

| Range Accuracy | + (0.75 m + sample interval + distance x 2.5 x 10-5) (Ignore error of refractive index) |

| Loss Testing Accuracy Distance Display Resolution | +0.02 dB/km (single mode); 10.2 dB/km (multiple mode); |

| Distance Display Resolution | 6.21 mi (0.0001 km) |

| Loss Threshold | 0.001 dB |

| Minimum Event Dead Zone | slm (single mode); $2 m (single mode) |

| Maximum Range Resolution | 3.10 mi (0.05 m) |

| Waveform Memory Capacity | 2800 Pieces (detail value varies with the memory capacity of the device) |

| Port | USB port, mini-USB port, SD card port |

| VFL | 650 nm 10 nm, 2 mW (typical); CW/1 Hz |

| Optical Power Meter | Wavelength range: 1270 nm-1700 nm

Measurement range: -60 dBm-3 dBm Measurement accuracy: 5 % (-10 dBm, CW) |

| Power Supply | AC/DC adapter: voltage allowable range: 100 V-240 V (1.5 A), frequency allowable range: 50 Hz/60 Hz

DC: 19 V±10% (2A) Lithium battery inside: 14.8 V, battery working time: 8 hours (normal temperature, low lightness, not sampling) |

| Operating Temperature | 32°F-122°F (0°C-50°C)

(Battery Charging: 41°F-104°F (5°C-40°C)) |

| Storage Temperature | 104°F-158°F (40°C-70°C)

(Battery: -4°F-140°F (-20°C-60°C)) |

| Relative Humidity | 5%-95% RH, non-condensation |

| Size | 11.61 in x 7.32 in x 2.95 in (295 mm x 186 mm x 75 mm) |

| Weight | About 5.95 lbs (2.7kg) |