Description

Overview

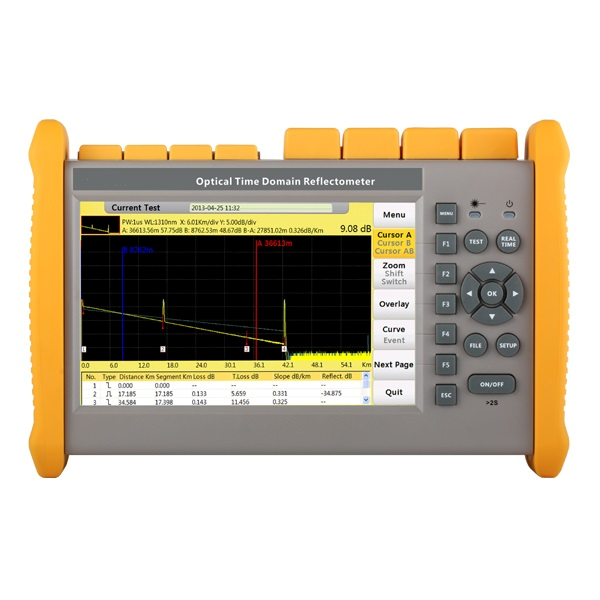

GAOTek’s OTDR with PON Online Test, Multimode and Fiber Microscope is a new generation of intelligent testing devices for fiber communications systems, GAO-OTDR-115 OTDR is specially designed for tough outdoor applications. IP65 protection level, lightweight, easy operation, low- reflection LCD and long battery life makes it perfect for the field testing. This device is a highly integrated platform with features like four module slots, large 7-inch color screen (with a touchscreen option), a high-capacity Lithium-Ion battery, an optional microscope (through universal serial bus [USB] port), and built-in optical test functions, such as PON test module, visual fault locator (VFL), optional power meter and laser source. The versatile features of this device make it suitable for the installation, turn-up, and maintenance of FTTX/Access optical networks.

Features

- Integrated design, smart and rugged.

- IP55 protection level outdoor enhanced,

- 7-inch anti-reflection TFT-LCD display with LED backlight (touch screen function is optional).

- A high-capacity Lithium-Ion battery with 12 hr operating time.

- Built-in VFL

- PON online test module (1625nm) (optional).

- Multi-mode test module (850/1300nm) (optional).

- Optional built-in power meter to verify the presence of the signal.

- Optional built-in Laser source to verify the total loss of the optical network.

- Optional fiber inspection probe to facilitate the Inspection before the connection.

- Support multi-language display and input.

- Can measure Splice loss. Connector loss, Fiber attenuation, Reflection of points, Link optical return loss and distance to fiber events etc.

- 4GB lorge internal memory space, con store more than 40,000 group of results

Applications

- FTTX test with PON networks

- CATV network testing

- Access network testing

- LAN network testing

- Metro network testing

- Lab and Factory testing

- Live fiber troubleshooting

- Technical Specifications

Technical Specifications

| TEST PARAMETERS | |

| Testing Wavelength

(MM: +20 nm, SM: +10 nm) |

Wavelength will vary with different module number. Please refer to the “Ordering Information” Table for more detail |

| Dynamic Range (dB | Dynamic range will vary with different module number. Please refer to the “Ordering Information” Table for more detail |

| Event/Attenuation Dead-zone (m | Event/Attenuation Dead-zone will vary with different module number. Please refer to the “Ordering Information Table for more detail. |

| Pulse Width | Single mode: 3 ns, 5 ns. 10 ns, 20 ns., 50 ns, 100 ns. 200 ns, 500 ns, 1 µs, 2 με 5 με 10 με 20 μα

Multimode: 3 ns, 5 ns. 10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns, 1 με 2 μα |

| Testing Distance | Single mode: 100 m, 500 m, 2km, 5 km, 10 km, 20km. 40 km, 80 km, 120 km, 160 km, 240 km

Multi-mode: 500 m, 2 km, 5 km, 10 km, 20 km, 40 km |

| Sampling Resolution | Minimum 5 cm |

| Sampling Point | Maximum 128,000 points |

| Linearity | Sampling Point |

| Maximum 128,000 points | $0.05 dB/dB |

| scale indication | X axis: 4m-70m/div, Y axis: Minimum 0.09dB/div |

| Distance Resolution | 0.01 m |

| Distance Accuracy | (1m+ measuring distance×3×10-5+sampling resolution) (excluding IOR uncertainty) |

| Reflectance Accuracy | Single moder: 2 dB. multi-mode: 4 dB |

| IOR Setting | 1.4000-17000, 0.0001 step |

| Units | Km, milles, feet |

| OTDR Trace Format | Telcordia universal, SOR, Issue 2 (SR-4731)

OTOR: User selectable automatic or manual set-up |

| Testing Modes | Visual fault locator: Visible red light for fiber identification and troubleshooting

Light source: Stabilized Light Source (CW, 270 Hz, 1 kHz, 2 kHz output) Field microscope probe |

| Visual Fault Locator (VFL) Module (Standard function) | |

| Wavelength (20nm) | 650 nm |

| Power | 10 mw, CLASSIII B |

| Range | 12 km

FC/UPC |

| Launching Mode | CW/2Hz |

| Wavelength Range (=20nm) | 800 nm-1700 nm |

| Calibrated Wavelength | 850 nm/1300 nm/1310 nm/1490 nm/1550 nm/1625 nm/1650 nm |

| Test Range | Type A:-65-5dBm (standard); Type B:-40-+23dBm (optional) |

| Resolution | 0.01 dB |

| Accuracy | +0.35 dB +1 nW |

| Modulation Identification | 270/1k/2 kHz, input > z-40dBm |

| Connector | FC/UPC |

| Optical Laser Source (OLS) Module (Optional function) | |

| Working Wavelength (20nm) | 1310 nm/1550 nm/1625 nm² |

| Output Power | Adjustable-25-0 dBm |

| Accuracy | +0.5 dB |

| Connector | FC/UPC |

| Fiber Microscope (FM) Module (Optional function) | |

| Magnification | 400X |

| Resolution | 1.0 µm |

| View of Field | 0.40 mm x 0.31 mm |

| Storage/working Condition | -0.4°F-95℉(-18-35) |

| Dimension | 9.25 in x 3.74 in x 1.18 in (235 mm x 95 mm 30 mm) |

| Sensor | 1/3 inch 2 million of pixel |

| Weight | 150 g |

| USB | 11/20 |

| Adapter | SC-PC-F (For SC/PC adapter)

FC-PC-F (For FC/PC adapter) LC-PC-F (For LC/PC adapter) 2.5PC-M (For 2.5mm connector, SC/PC, FC/PC, ST/PC) |

| GENERAL SPECIFICATIONS

|

|

| Display | 7 inch TFT-LCD with LED backlight (touch screen function is optional) |

| Interface | 1-RJ45 port, 3 USB port (USB2.0 Type A USB 2 Type B USB×1) |

| Power Supply | 10 V (dc), 100V(ac) to 240V(ac), 50-60Hz |

| Battery | 7.4 V (dc)/4.4Ah lithium battery (with air traffic certification) |

| Operating Time | 12 hours. Telcordia GR-195-CORE

<4 hours (power off) |

| Power Saving | |

| Language | User selectable English, Simplified Chinese, traditional Chinese, French, Korean, Russian, Spanish and Portuguese contact us for availability of others |

| Environmental Conditions |

|

| Dimension | 9.96 in x 6.61 in x 2.89 in (253 mm x 168 mm x 73.6 mm) |

| Weight | 3.31 lbs. (1.5 kg) (battery included) |